Patents

Literature

39results about How to "Solve the fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Core-shell type fluorinated acrylate fabric water repellent and preparation method thereof

ActiveCN103788303AExcellent water and oil repellencyDoes not affect breathabilityFibre treatmentEmulsionMoisture permeability

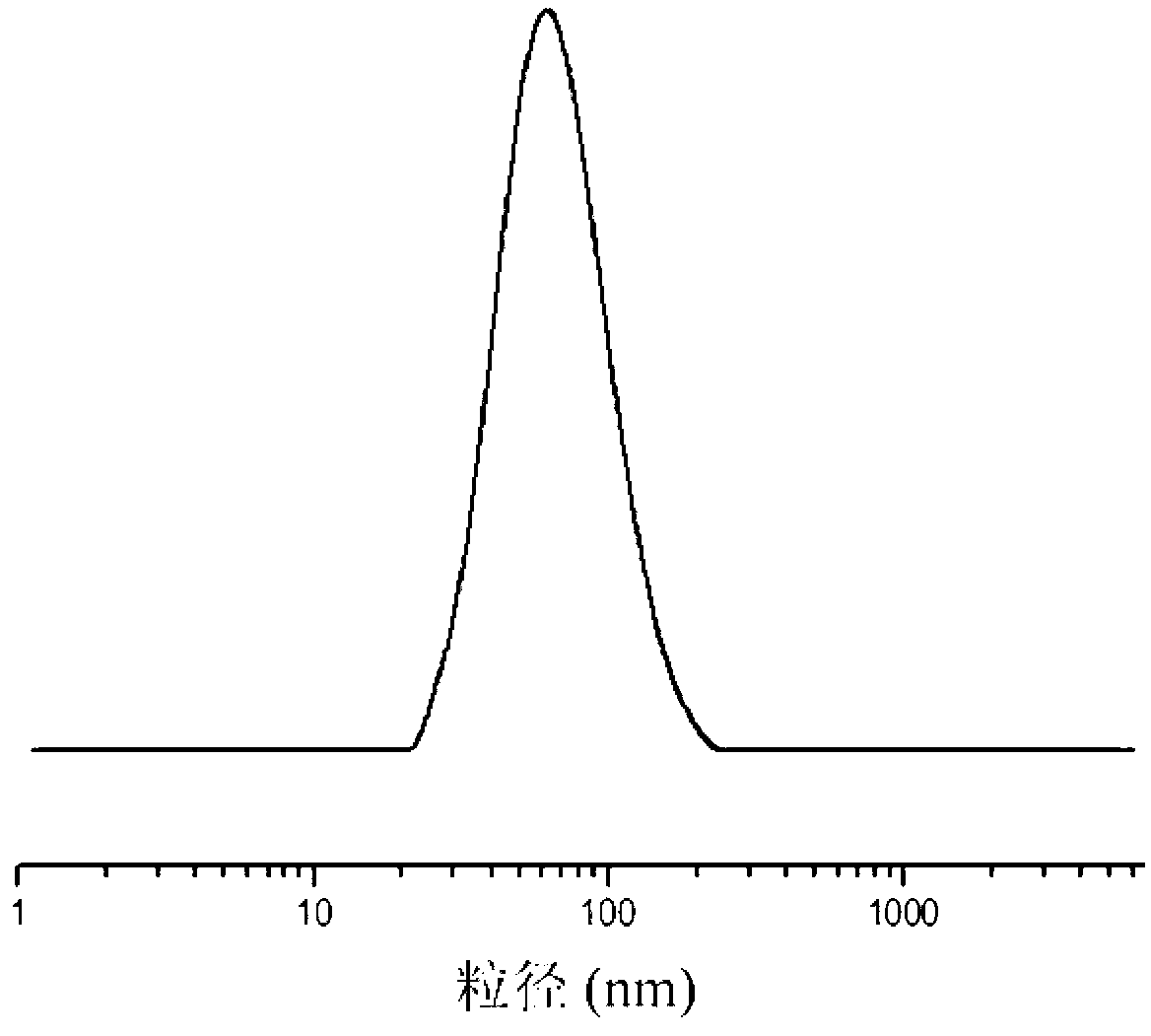

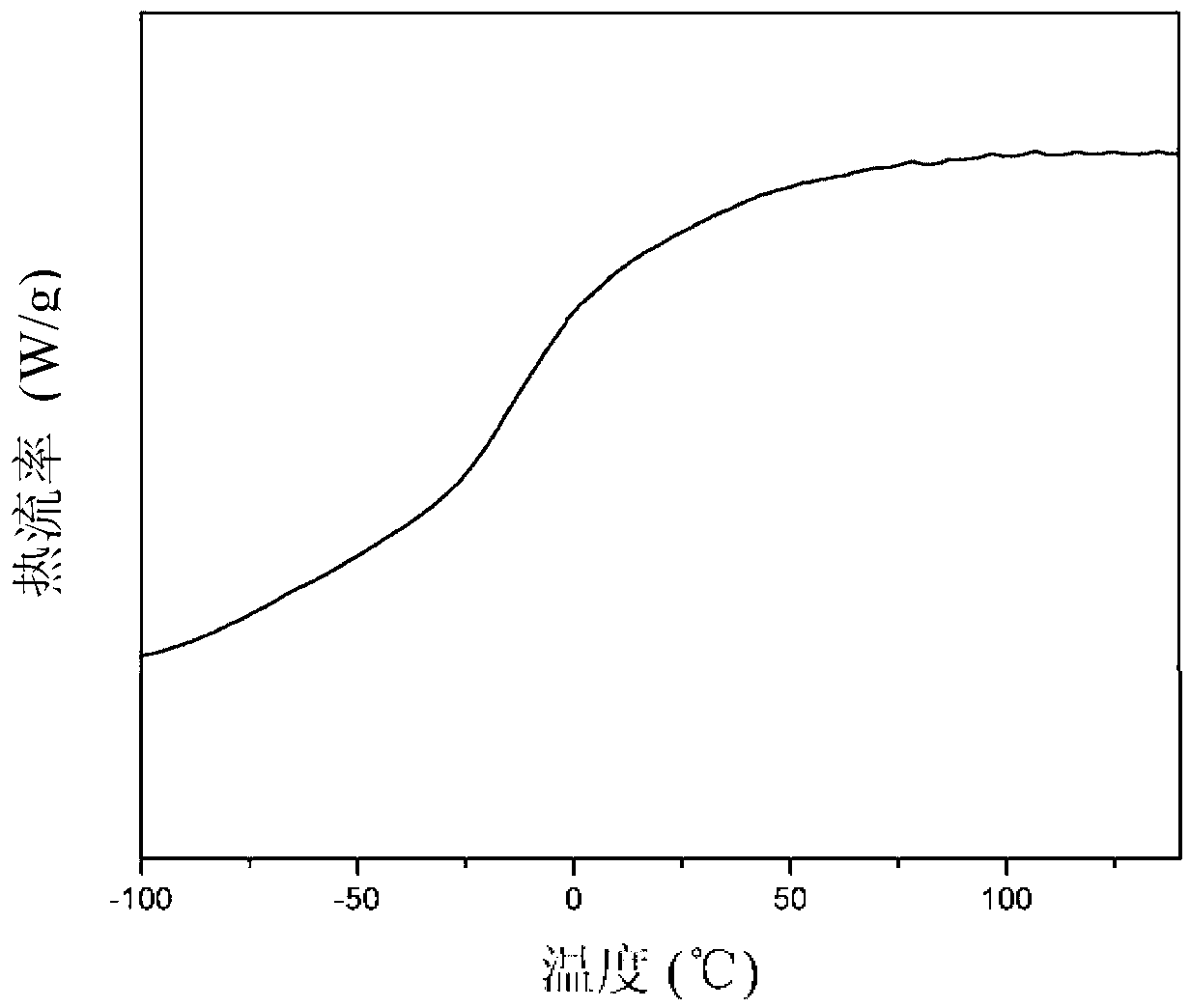

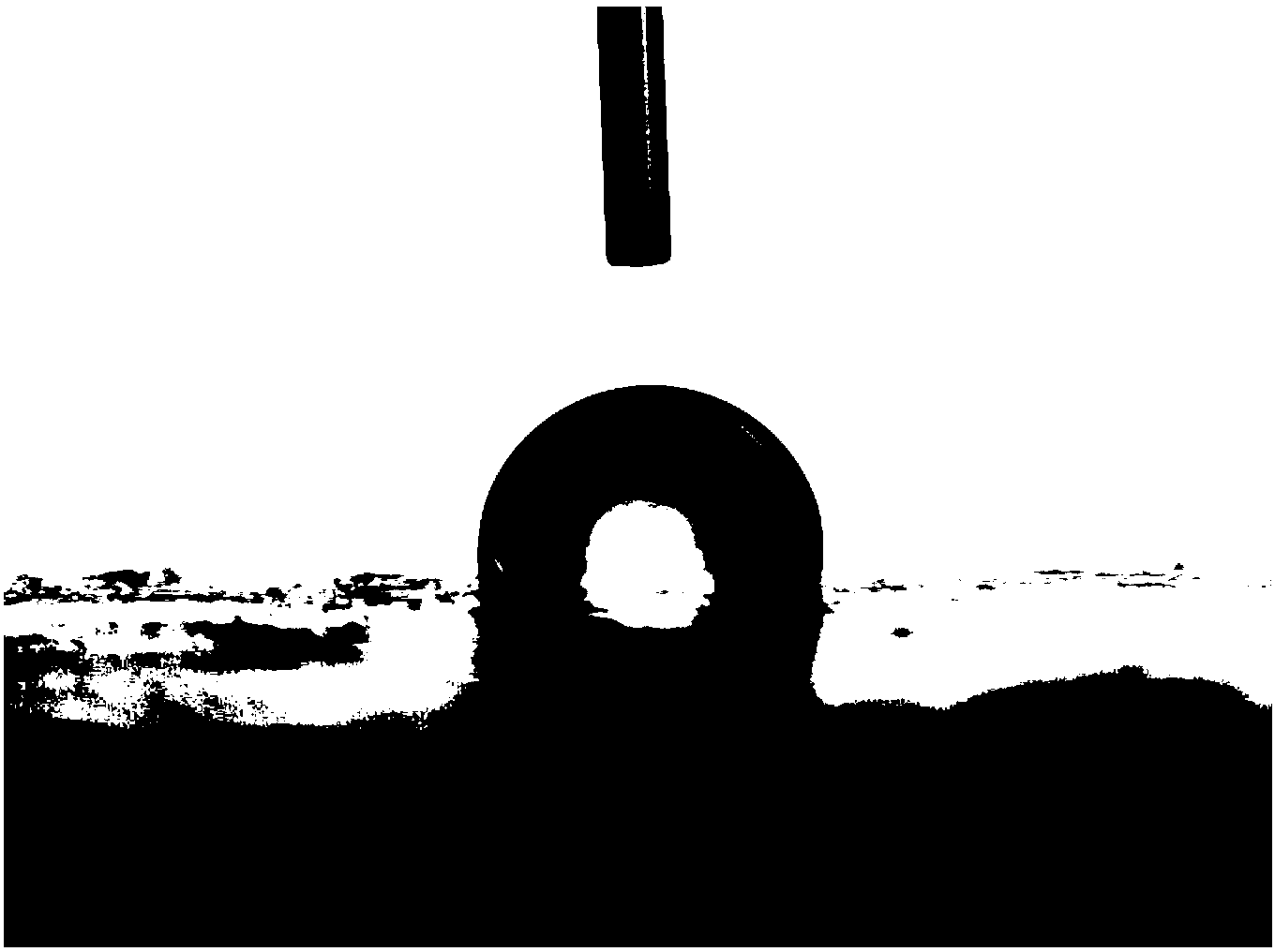

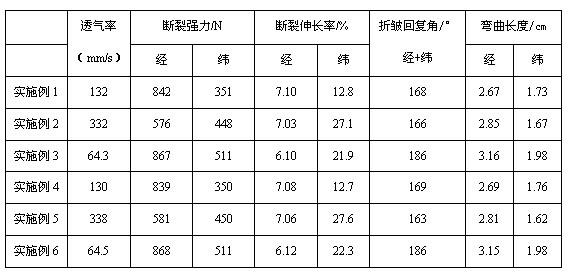

The invention relates to a core-shell type fluorinated acrylate fabric water repellent which comprises the components by weight percent: 25-50% of monomer, 50-75% of deionized water, an initiator and an emulsifying agent, wherein the weight of the initiator is 0.5-1.5% of the total weight of the monomer, and the weight of the emulsifying agent is 1.0-3.5% of total weight of the monomer. A preparation method of the water repellent comprises the steps of respectively preparing shell emulsion and core emulsion, and then dripping the shell emulsion and the initiator into the core emulsion for reaction to obtain the core-shell type fluorinated acrylate fabric water repellent. The core-shell type fluorinated acrylate fabric water repellent is applied to water and oil repellent finishing of the fabric, so that the fabric has excellent water and oil repellent property, and the problems that the existing water and oil repellent is poor in use durability, low in fastness and the like in the aspect of wearability can be solved; furthermore, the performances such as air permeability, moisture permeability and the like of the fabric are not influenced, and the environmental pollution is not caused.

Owner:广东奕美化工科技有限公司

Environmental protection type dye printing paste without steaming and washing

ActiveCN101105004AEliminate steaming and washing processSolve the feelDyeing processDisperse dyeAs Directed

The invention discloses an environment-friendly steam- / wash-free dye printing paste, which is implemented by re-formulating monomer components partially in the prior binder. The steam- / wash-free binder can meet the requirement of random combination with acidic dyes, active dyes and disperse dyes; and is suitable for both manual and mechanical printing. The product printed with the blend of synthetic steam- / wash-free binder has bright color, clear pattern, high color yield, uniform printing block, good flowability, and soft touch. The invention is suitable for various printing processes such as direct printing, discharge printing and burnt-out printing, and is also used for printing various textile fabrics after mixing with other dyes. The invention simplifies the printing process, solves the environmental problem of the prior printing process, and avoids the environmental pollution of waste water.

Owner:丁志平

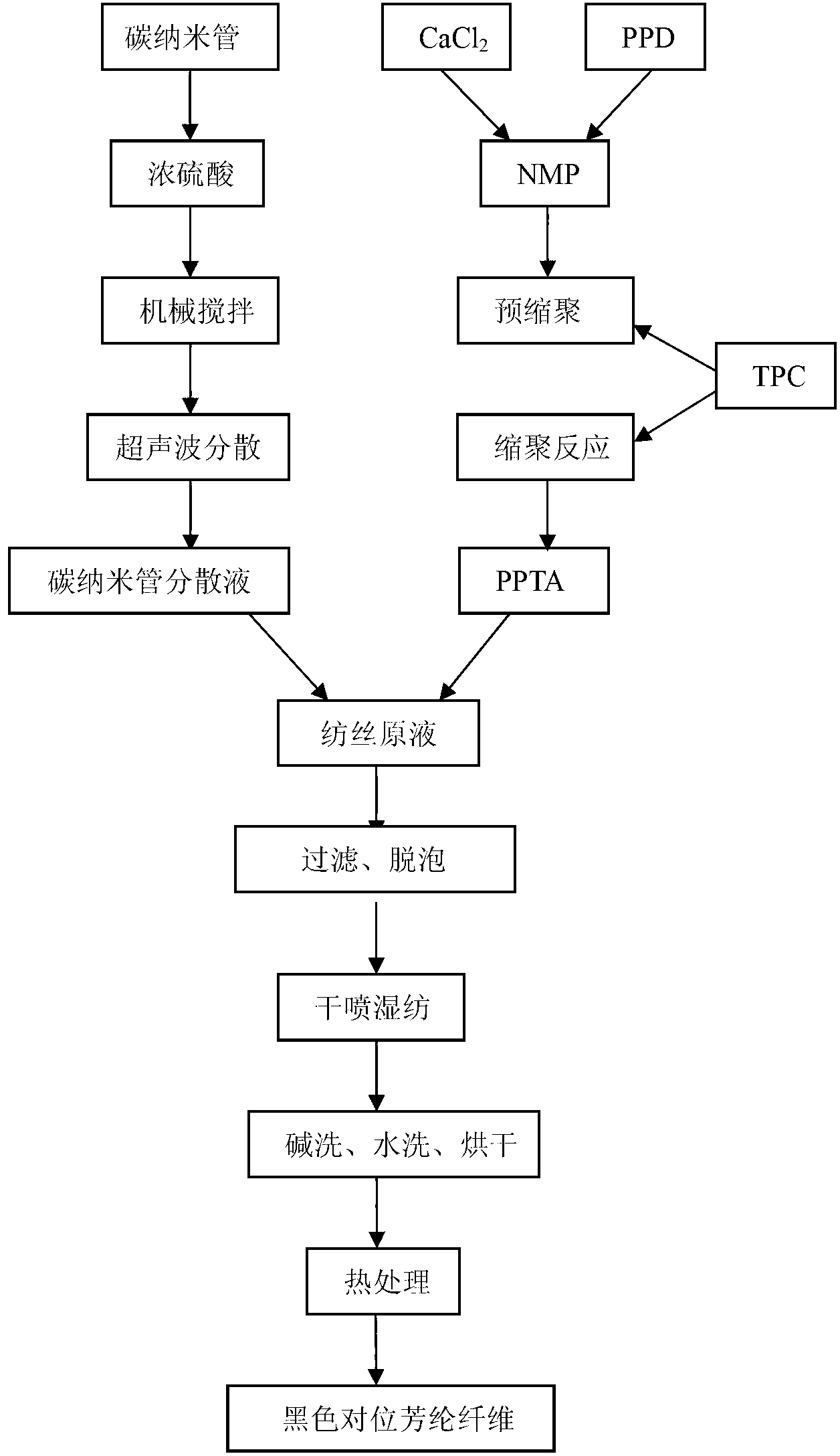

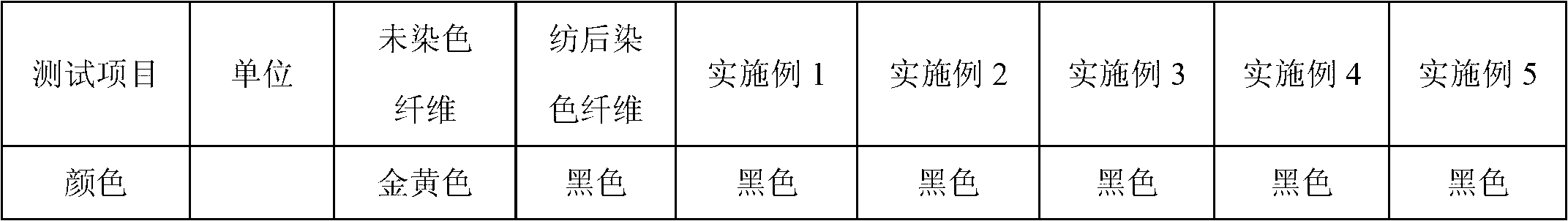

Preparation method of black p-aramid fiber

ActiveCN102839444AHigh strengthEvenly dispersedPigment addition to spinning solutionMonocomponent polyamides artificial filamentCarbon nanotubeUltimate tensile strength

The invention relates to a preparation method of black p-aramid fiber. The black p-aramid fiber obtained by the preparation method has high fiber strength and is fadeless. The preparation method comprises the following steps of: (1) dispersing multi-walled carbon nanotubes in concentrated sulfuric acid to obtain carbon nanotube dispersion, wherein the weight ratio of the multi-walled carbon nanotubes to concentrated sulfuric acid is 1:(100-500), the average wall number of the multi-walled carbon nanotubes is 2-6, the average diameter of the multi-walled carbon nanotubes is 1-20nm, and the average length of the multi-walled carbon nanotubes is 0.5-20mu m; and (2) dissolving poly-p-phenylene terephthamide to the carbon nanotube dispersion to obtain a spinning stock solution, filtering and debubbling the spinning stock solution, spinning by a dry-jet wet spinning method, washing with base, washing with water, drying and carrying out heat treatment to obtain the black p-aramid fiber, wherein the weight ratio of poly-p-phenylene terephthamide to the carbon nanotube dispersion is 1:(3.9-4.1), and the intrinsic viscosity of poly-p-phenylene terephthamide is 6-8dL / g<3>.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

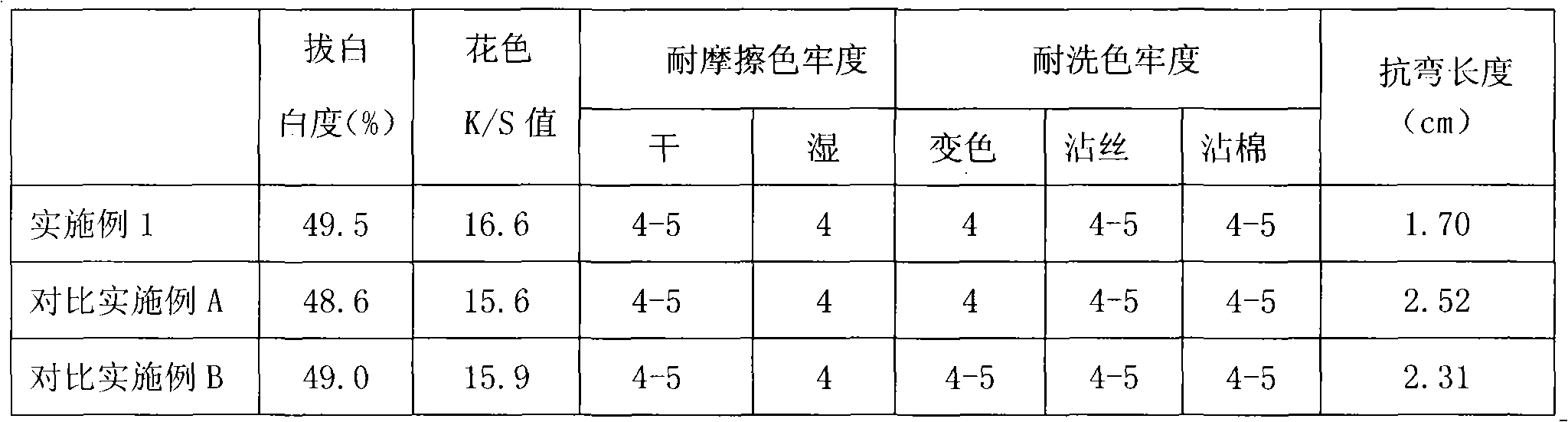

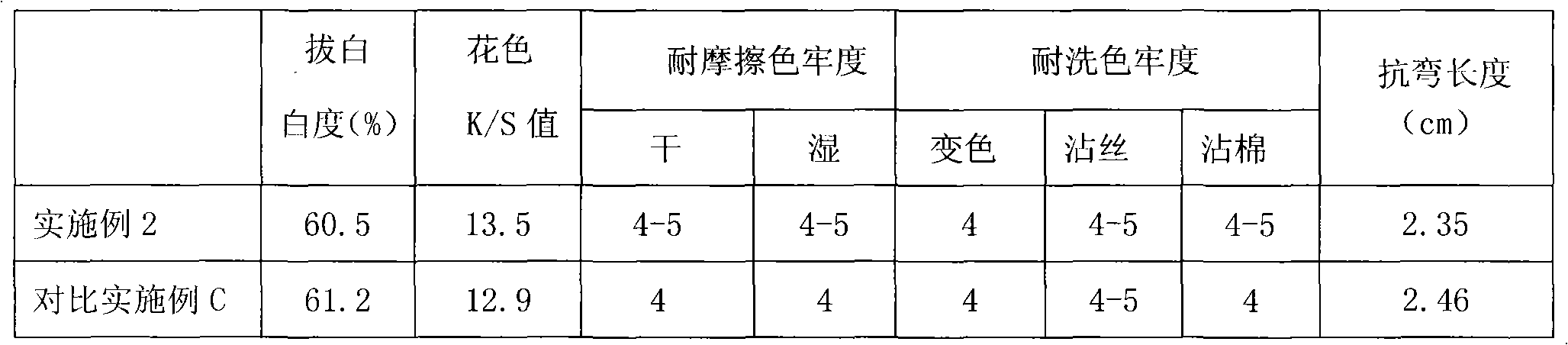

High-fastness natural dye printed product and preparation method thereof

ActiveCN104894891ASolve the problem of excessive heavy metals in printingSolve the hard feelingFibre treatmentDyeing processPre treatmentNatural dye

The invention provides a high-fastness natural dye printed product and a preparation method of the high-fastness natural dye printed product. The method comprises the following steps: performing pre-treatment and cationic modification on a fabric; preparing a cation removing printing work liquid, performing cation removing printing on the fabric after the cationic modification, and baking or steaming; and dyeing the fabric after the cation removing printing by using a natural dye so as to obtain the high-fastness natural dye printed product. The preparation method disclosed by the invention can be used for solving the problems that heavy metal in a natural dye printed product is out of standard, the hand feeling is slightly hard, the color fastness is poor, the large-area bottom color is not uniform, and the like.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

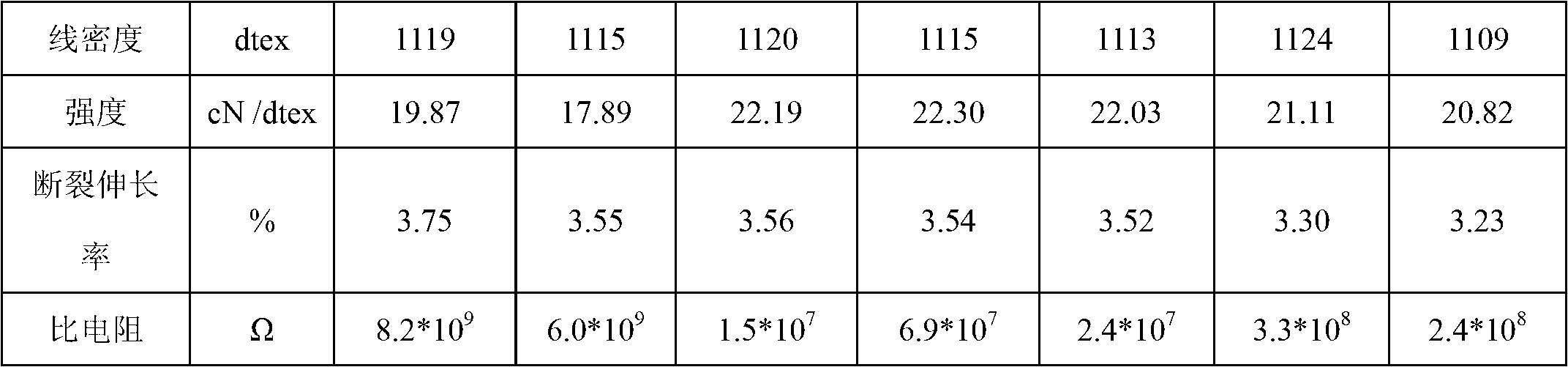

Dyeing method of cellulosic fiber fabric

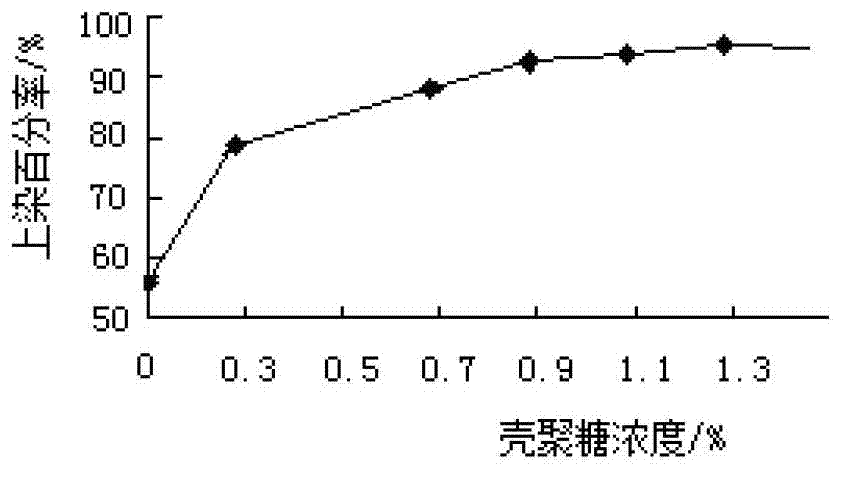

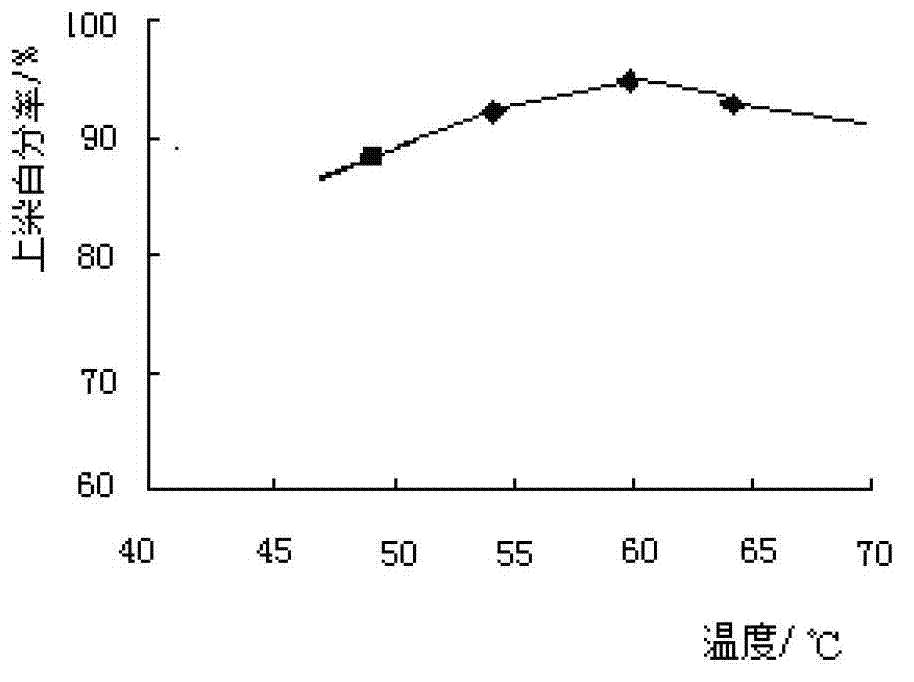

InactiveCN102817239ASolve the low dyeing rateSolve the fastnessDyeing processVegetal fibresPerformance indexCellulose fiber

The invention discloses a dyeing method of a cellulosic fiber fabric, comprising the following steps of: firstly, performing pretreatment modification on the cellulosic fiber fabric by using chitosan; then, preparing a dye solution; and finally, putting the modified cellulosic fiber fabric in the dye solution for dying. In the dyeing method, the cellulosic fiber fabric is modified by using the chitosan as a deep dyeing agent and then is pretreated at the temperature of 50 DEG C, the modified cellulosic fiber fabric is dyed by using an activated dye, and a color fixing alkali agent is added for fixing the modified cellulosic fiber fabric so that the dye is fixed on fiber. The dyeing rate of the dyed cellulosic fiber fabric can be up to above 90%, and the soaping fastness is improved by 1 level or more than 1 level. The color of the dyed cellulosic fiber fabric is fundamentally in accordance with the color of fiber not dyed by the chitosan, and all performance indexes meet the natural standard.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Environment protection type coating discharge printing pulp and discharge printing process thereof

InactiveCN101408003AHigh-quality discharge printing effectSolve health and environmental protectionDyeing processAdhesiveEnvironmental engineering

The invention provides an environment-friendly paint discharge printing discharge paste and a discharge printing technology thereof. The environment-friendly paint discharge printing discharge paste comprises paint discharge printing white discharge paste and paint discharge printing color discharge paste: the paint discharge printing white discharge paste is a mixture formed by 100 parts by weight of discharge resistant composite thickening paste, 1.5 to 2 parts by weight of softener, 4 to 6 parts by weight of wetting penetrant and 3 to 7 parts by weigh of discharging agent, which are uniformly mixed; the paint discharge printing color discharge paste is a mixture formed by 100 parts by weight of the discharge resistant composite thickening paste, 10 to 20 parts by weight of adhesive, 1.5 to 2 parts by weight of the softener, 4 to 6 parts by weight of the wetting penetrant, 3 to 7 parts by weight of the discharging agent and 1 to 5 parts by weight of discharge resistant paint, which are uniformly mixed. By applying the discharge paste to carry out discharge printing, not only water and energy are saved and environment is protected, but also the whiteness of the white discharge printing is guaranteed to be high, the color fastness of the fabrics after the paint color discharge printing is high, and hand feeling is soft.

Owner:ZHEJIANG SCI-TECH UNIV

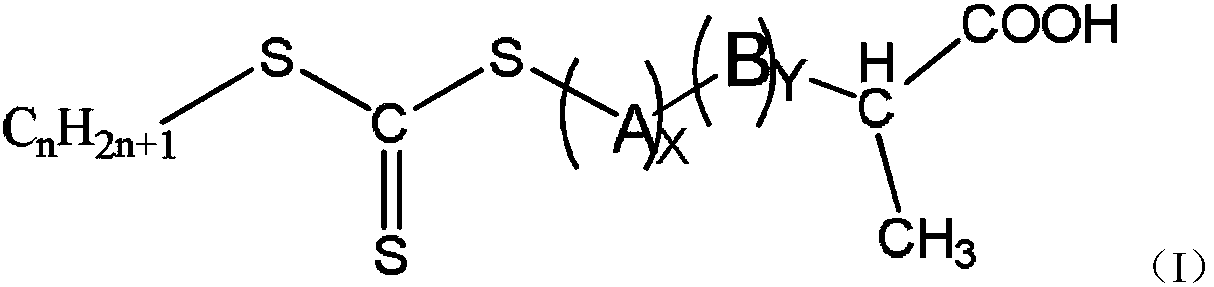

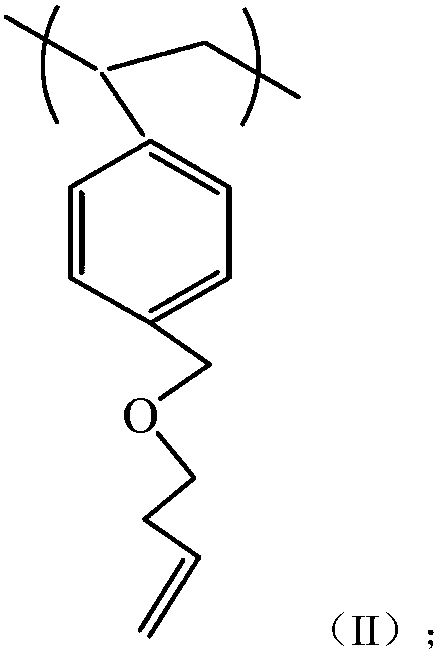

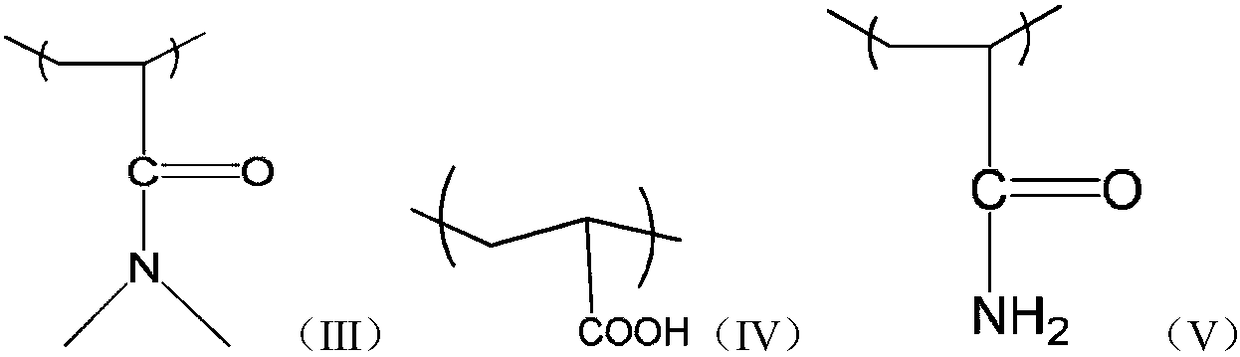

Fluorine-silicon-modified acrylate adhesive, preparation method and application thereof

ActiveCN103224765ASolve the feelSolve the fastnessEster polymer adhesivesDyeing processEmulsionAdhesive

The invention discloses a fluorine-silicon-modified acrylate adhesive which is prepared by the following raw materials by weight parts: 50 parts of water, 0.1-1 part of an anionic emulsifier, 10-20 parts of acrylate polymerizable monomers, 0.2-1 part of acrylic acid, 0.5-5 parts of fluorine containing organosilicon monomers, 0.1-2 parts of co-emulsifier and 0.1-1 part of an initiator. The fluorine-silicon-modified acrylate adhesive is a stable fluorine-silicon-modified acrylate emulsion, can be used for pigment printing, is soft in touch, high is color fastness, good in system stability and stable in product quality, and effectively solves problems of incompatible touch and fastness, and hot sticking and cold shortness existing in present acrylate adhesives. The invention further discloses a preparation method of the fluorine-silicon-modified acrylate adhesive. According to the method, stable fluorine-silicon-modified acrylate emulsion is prepared through miniemulsion polymerization. The method is simple in preparation, easy to implement and operate, and easy for industrial production, and has wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Fabric pigment dyeing and roll-drying resist-dyeing process

InactiveCN102140766ASolve the fastnessSolve the sticky rollDyeing processColour fastnessPolymer science

The invention relates to a fabric pigment dyeing and roll-drying resist-dyeing process which comprises the following steps: respectively dipping and rolling a fabric twice on a uniform rolling vehicle by using pigment dyeing liquid, wherein the rolling waste rate is 60%-70%; then drying the fabric by infrared rays or hot air at the drying temperature of 70-80 DEG C; after drying the fabric, dipping and rolling the fabric twice again by using the same pigment dyeing liquid or different pigment dyeing liquid, wherein the rolling waste rate is 60%-70%; then drying the fabric by the infrared rays or the hot air at the drying temperature of 70-80 DEG C; and finally carrying out color fixation for 2-5 min. By using a dipping and rolling resist-dyeing process for replacing the traditional dipping and rolling dyeing process, the invention realizes deep dyeing with low-concentration dyeing liquid, and a flexible bonding agent matched with high-fastness bonding agent is applied to pure cotton and cotton / terylene blended fabrics so that the problems of poor color fastness, roller sticking, hard hand feeling of the dyed fabric and the like appearing in a pigment deep-color dyeing process of the cotton and cotton / terylene blended fabrics. By adopting the process, as the fabric does not need to be modified and washed in water after being dyed, except the condition that the preparation of dyeing liquid and the cleaning of a machine need water in a dyeing process, water is hardly needed, therefore, the problem of dyeing water consumption is fundamentally solved.

Owner:HENAN INST OF ENG

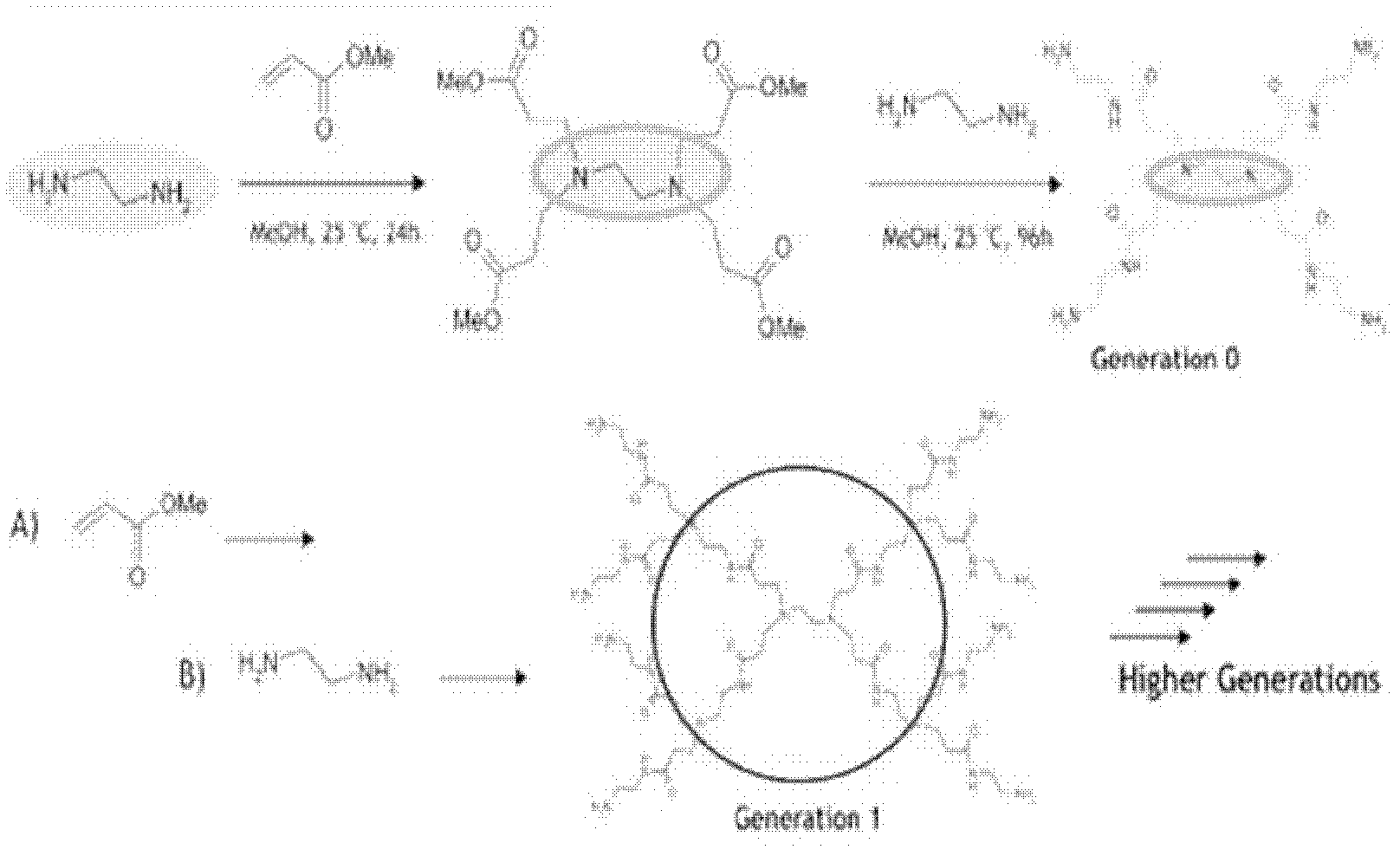

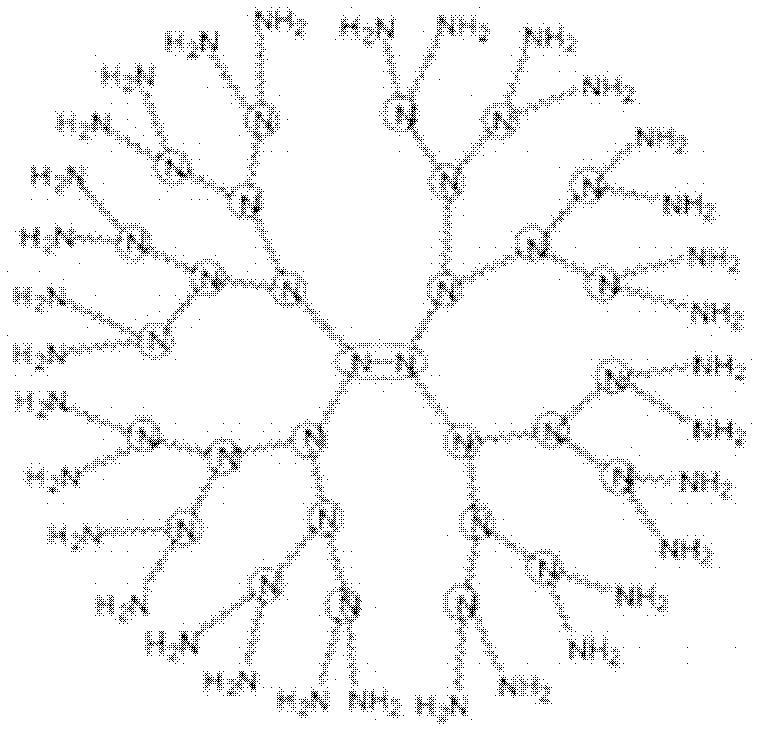

Activation method for electromagnetic shielding fabrics before chemical plating based on PAMAM (polyamidoamine)/ palladium ligand

InactiveCN102634778ANot easy to fall offSolve associativityMagnetic/electric field screeningFibre treatmentActivation methodChemical plating

The invention relates to an activation method for electromagnetic shielding fabrics before chemical plating based on PAMAM (polyamidoamine) / palladium ligand. The activation method includes four steps of preparing PAMAM dendrimer solution; preparing dendrimer PAMAM-palladium activating finishing liquor; performing fabric activation; and performing chemical plating. Compared with the prior art, theinvention provides a simple, convenient and stable preparation method for an activating agent with a high-efficient catalysis effect and the activation processing method before chemical plating. Accordingly, the activation method has excellent advantages that metal chemical initial plating of the electromagnetic shielding fabrics is easy, a plating layer is uniform and firm, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

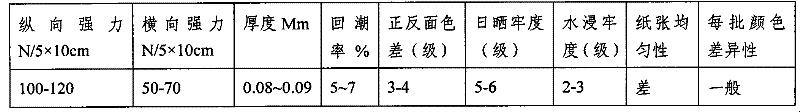

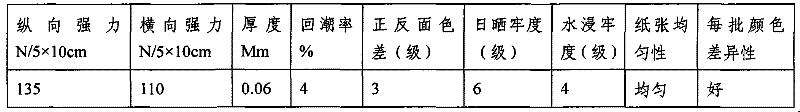

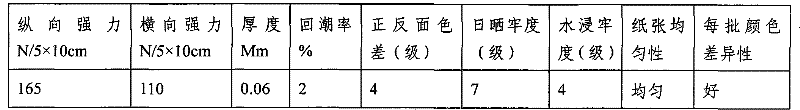

Method for preparing dyed wood pulp paper for nonwoven materials

ActiveCN102230296AChange the dyeing processSolve the fastnessNatural cellulose pulp/paperPaper/cardboardFluff pulpSlurry

The invention discloses a method for preparing dyed wood pulp paper for nonwoven materials, which comprises the following steps of: (1) mixing red pine fluff pulp and coniferous wood pulp to obtain mixed wood pulp; (2) dispersing the pulp, namely putting the mixed wood pulp obtained in the step (1) into a pulp dispersing tank, and adding water for pulping, so that wood pulp fibers are dispersed in the water uniformly; (3) heating, namely heating the water in the pulp dispersing tank; (4) dyeing, namely dyeing dyes in the pulp dispersing tank for 15 to 30 minutes, adding a color fixing agent, and fixing colors for 20 to 30 minutes; and (5) conveying dyed slurry obtained in the step (4) into a fourdrinier part of a papermaking machine for forming, and squeezing, drying, coiling and slittingto obtain the dyed wood pulp paper for the nonwoven materials. Compared with imported wood pulp paper, the dyed wood pulp paper produced by the method has the advantages that: the color fastness to sunlight and water leaching fastness are improved greatly; indexes are higher than the level of foreign products; and the cost is reduced.

Owner:XINLONG HLDG GROUP

Method for chemical modification, pigment dyeing and overflow sand washing of fiber

InactiveCN101736579AEmbody noveltyEmbody creativityBiochemical fibre treatmentDry-cleaning apparatus for textilesFiber ChemistryCellulose fiber

The inventions discloses a method for chemical modification, pigment dyeing and overflow sand wash of a fiber and application thereof to garment dyeing. The method comprises the following steps of: carrying out an anode chemical modification reaction on a cellulosic fiber of a fiber product by using a cation denaturing agent under the non-alkali condition of a fiber product; and then carrying out pigment dyeing and overflow sand wash treatment to enable the fiber product to form the traditional stone washing old-coped effect. Compared with the traditional processing technology, the invention has the advantages that: the hand feeling and the firmness of the products can be improved by modifying the fiber for pigment dyeing, and meanwhile, the technology can be simplified, the process can be shortened, and the consumption and the pollution can be reduced. The invention solves the quality problems on the hand feeling, the firmness, the color reproducibility and the like in traditional garment stone milling treatment.

Owner:鞍山博亿印染有限责任公司

Digital printing process for real silk fabric

InactiveCN106758384AHigh color yieldIncrease color depthUltrasonic/sonic fibre treatmentDyeing processWarm waterEngineering

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following procedures: real silk fabric preparation; low-temperature plasma processing; pretreatment liquid padding; drying; inkjet printing; drying; dry heat fixation; cold water flushing; warm temperature washing; soaping; warm water cleaning; and drying, wherein pretreatment liquid in the pretreatment liquid padding contains the following components by contents: 5g / L-10g / L of sodium alginate, 30g / L-50g / L of baking soda, 30g / L-50g / L of urea and 5g / L-15g / L of a defoaming agent. By virtue of the digital printing process, the tinctorial yield of the digital printing of a silkworm silk fabric is increased, the color depth of the digital printing on a textile is increased, and the chromatic aberration with an electronic pattern is reduced; and furthermore, the color fastness is high, and multiple experiments prove that the fabric does not fade or lose color even at relatively hostile experimental environments.

Owner:顾朝晖

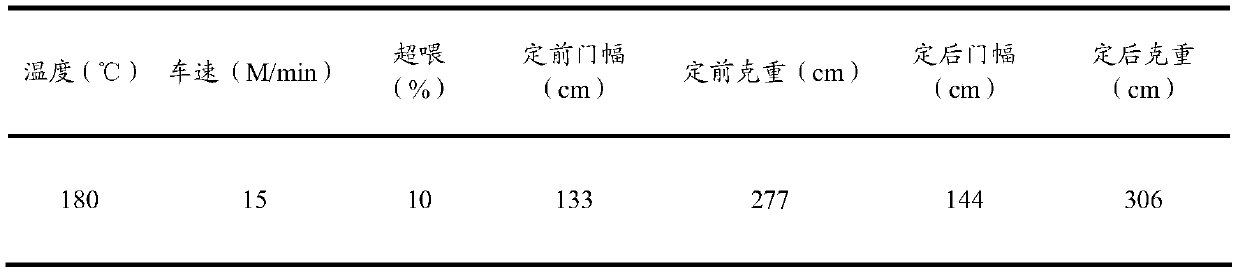

Production process of high-density nylon fabric

InactiveCN103696282ASolve the problem of high temperature yellowingSolve the poor anti-ultraviolet effectFibre typesDyeing processAcetic acidCooking & baking

The invention discloses a production process of a high-density nylon fabric. The process comprises the following steps: (1) unwinding and sewing; (2) performing desizing pretreatment; (3) presetting at 170 DEG C, namely adding 5-6g / L isopropanolamine and a 30g / L anti-yellowing agent, wherein the liquid content is 40 percent; (4) dyeing; (5) fixing color, adding a 5g / L anion color fixing agent and 4g / L acetic acid, performing color fixing treatment for 50 minutes and washing with clear water; (6) dehydrating and scutching; (7) carrying out after finishing, namely adding a 30g / L water-proofing agent, a 5g / L silicone softening agent, a 8g / L crosslinking agent and 4g / L fatty alcohol-polyoxyethylene ether, wherein the liquid detention rate is 40 percent, the drying temperature is 120 DEG C and the baking temperature is 190 DEG C; and (8) calendering. By adopting the production process, the problems of easiness in high-temperature yellowing, poor ultraviolet resistance, poor water repellency, poor oil repellency, poor water washing resistance, low color fastness, not ideal downproofness and the like due to the adoption of a non-reasonable production process in the existing production process of high-density nylon fabrics are solved.

Owner:常熟市爱博尔服饰有限公司

Polyester Chenille spinning method and product

The invention provides a polyester Chenille spinning method and product. The method comprises the steps of: dyeing wool yarns and core yarns respectively, and then rewinding and spinning to obtain Chenille; next, carrying out fixation clearing on the Chenille twice, and weaving; and then treating obtained textile by open width drying. The polyester Chenille product is characterized in that: two 16S large yarns are used as the core yarns, and two 150D / 288F interlaced yarns are used as the wool yarns, wherein the value of leaf gauge is 3 mm, and the degree of twist of the core yarns is 700; and 2.7N Chenille is spun. The polyester Chenille spinning method disclosed by the invention can solve the problems in binding print and poor color fastness in the dyeing progress of the polyester Chenille, can avoid chromatic aberration, better control color, and realize the purpose of avoiding core exposure after spinning. The polyester Chenille product can replace viscose Chenille, thereby not only improving appearance effect but also reducing raw material cost.

Owner:YIXING ZHONGDA TEXTILE

Dyeing and finishing technology of Lyocell and cotton and spun silk blended fabric

InactiveCN102926236ASolve the consistency of dyeing the same colorThe dyeing process is reasonableDry-cleaning apparatus for textilesBleaching apparatusEngineeringLyocell

The invention relates to a blended fabric dyeing and finishing technology, and particularly relates to a dyeing and finishing technology of a Lyocell and cotton and spun silk blended fabric. The invention aims at providing a dyeing condition capable of well coordinating Lyocell and cotton and spun silk to produce a high-quality product. The dyeing and finishing technology of the Lyocell and cotton and spun silk blended fabric comprises the processes of pretreatment, dyeing and the like; the pretreatment process comprises desizing and bleaching, wherein the desizing is performed by an enzyme-oxygen cold batch technology, and desizing enzyme, a chelating dispersant, a dewaxing agent and a refining agent are added in the desizing process; and 100% hydrogen peroxide and a stabilizer are added in the bleaching process. Through the invention, the problems of difficult color register and long technological flow are successfully solved; and through the method, the dyeing flow of the fabric is more reasonable, the production is clean and environment-friendly, and the product quality is stable.

Owner:HUAFANG

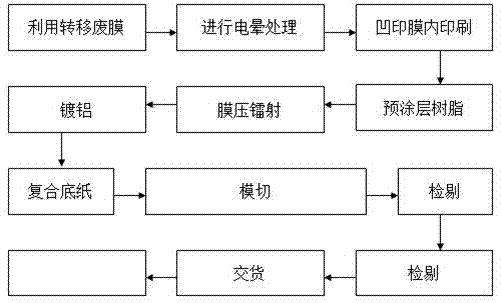

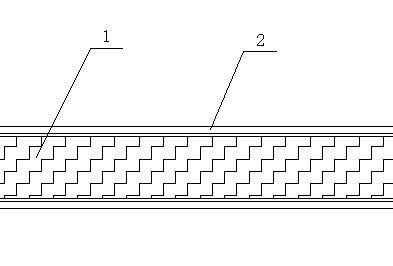

Inner-layer printing and laser composite paper manufacturing technology

InactiveCN105437721ASolve the problem of easy chafingSolve the fastnessLamination ancillary operationsLaminationPaper manufacturingProcess engineering

The invention discloses a novel inner-layer printing and laser composite paper manufacturing technology. A transferred waste film is subjected to corona pretreatment firstly, then film inner surface printing, film pressing and aluminizing are performed sequentially, and a backing paper product is composited. With the adoption of the technology, the production efficiency is improved greatly, the product cost is reduced, and the product competitiveness is enhanced. The technology has the advantages that the cost is greatly reduced, and problems about ink fastness and product scratching are solved.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

Production technology for indigo cotton yarn

The invention discloses a production technology for indigo cotton yarn. The production technology comprises the steps of blowing, carding, first drawing, second drawing, third drawing, roving, spinning and post processing, and specifically comprises the steps that firstly, indigo dye coating is molten to be prepared into a leuco body for use; secondly, preprocessed cotton is put into the indigo dye coating, the temperature is increased to 35 DEG C at a speed of 3 DEG C / min, temperature keeping is conducted for 30 min, the temperature is increased to 120 DEG C at a speed of 2 DEG C / min, dyeing continues to be conducted for 20 min, the temperature is decreased to 40 DEG C at a speed of 3 DEG C / min, and the cotton is taken out; thirdly, blowing, carding, first drawing, second drawing, third drawing, roving and spinning are conducted on the dyed cotton so that the cotton can be spun into cotton yarn for use; fourthly, post processing is conducted on the dyed cotton yarn, and post processing comprises drafty oxidation for 5 min, soaping and stoving, soap washing liquor is formed by adopting anhydrous sodium carbonate of 2 g / L and standard soap flakes of 5 g / L, the temperature is 60 DEG C, time is 20 min, and soap boiling, washing and stoving are conducted on the oxidized fabric.

Owner:源兴纺织(深圳)有限公司

Mosquito-repellent summer quilt and production method thereof

ActiveCN103654001AWashableReduce stayFilament/thread formingAnimal repellantsWeather resistanceEngineering

The invention provides a mosquito-repellent summer quilt and a production method thereof. Citronella essential oil and eucalyptus essential oil are added during coverlet production to achieve the mosquito-repellent effect, and a composite spinning method and a decal-process finishing process are adopted to add the citronella essential oil and the eucalyptus essential oil in a core layer so as to ensure the durable mosquito-repellent effect of the essential oil. In addition, the mosquito-repellent effect is enhanced by setting coverlet colors and utilizing the habit of keeping away from orange or red-orange of mosquitoes. By using the mosquito-repellent summer quilt and the production method, the durable mosquito-repellent effect can be achieved, the mosquito-repellent summer quilt has good handfeel and is antifouling, friction-resisting and good in washing-resistance fastness, weather resistance and other performances, and the core problems of handfeel, color brightness, color fastness, environment protection and the like of printed and dyed fabrics are solved. The mosquito-repellent summer quilt is produced to be orange or red-orange during printing and dyeing and can repel the mosquitoes and decrease the mosquitoes straying nearby the summer quilt.

Owner:江苏梦香家纺有限公司

Cotton loose fiber dyeing method

InactiveCN1528975ASmall chromatic aberrationReduce lossDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberChemistry

The invention discloses a dyeing process method for loose fiber of cotton, sliver, and cotton roll. It includes changes the traditional process of spinning-before-dyeing into the one of dyeing-before-spinning. The method uses azo dyes to dye the loose cotton, the dyed loose cotton is colorful cotton with five colors, the color includes red, yellow, brown and black. It can be produced without special appliances, especially applies to small industry, the color difference of the product is small, the product is soft, pluffy, it solves the problem of color floating, fading, contaminating, cotton joint, bad color firm rate. It reduces yarn back, high speed cone winding process.

Owner:余姚久丰染色厂有限公司

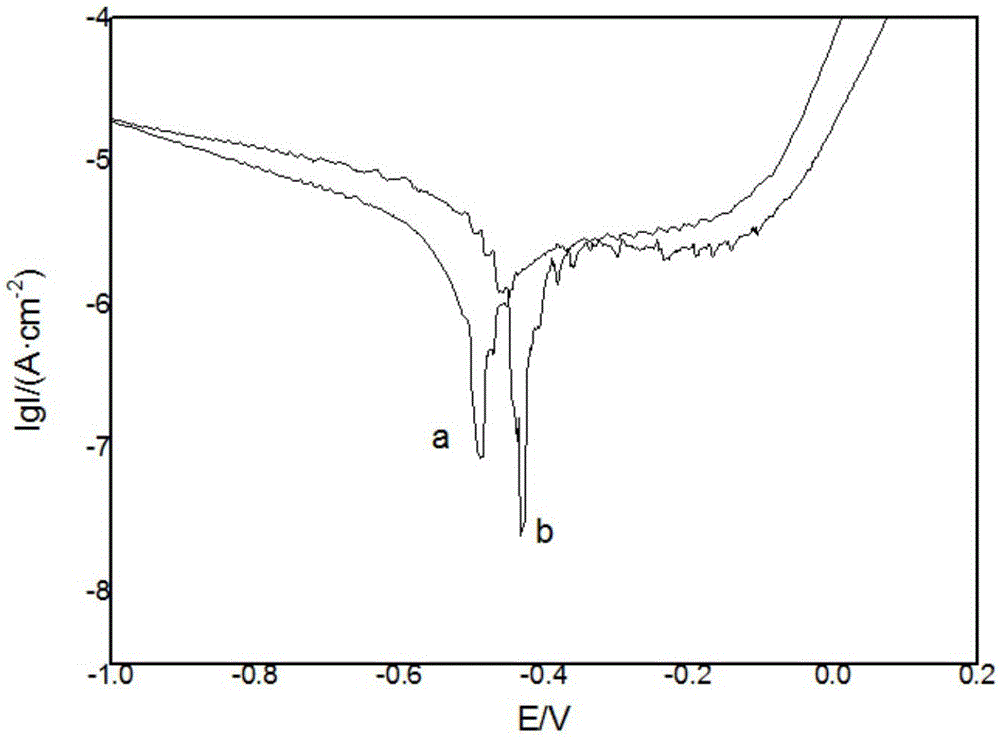

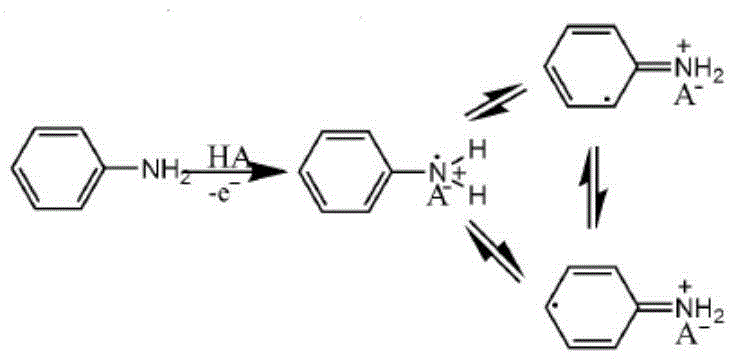

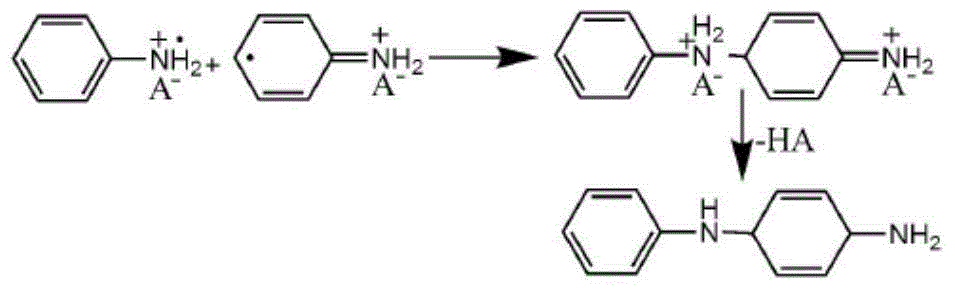

Preparation method of titanium dioxide-polyaniline composite corrosion-resistant coating

ActiveCN105111925AShort processSimple process controlAnti-corrosive paintsTitanium dioxidePolyaniline compositeCopper

The invention discloses a preparation method of a titanium dioxide-polyaniline composite corrosion-resistant coating. According to the preparation method, the steps of preparing nanometer titanium dioxide, synthesizing titanium dioxide-polyaniline, coating the surface of a metal plate with the titanium dioxide-polyaniline, and the like are synchronously carried out in a hydrothermal reaction kettle, and are completed through one step. The technical problem in the prior art that nanometer titanium dioxide is easy to agglomerate in a mixed solution system comprising the nanometer titanium dioxide and polyaniline is solved well, the technological process is greatly shortened, and the process control difficulty is reduced; besides, the step of heating and drying the composite coating required in the prior art is eliminated, and a series of technical problems that a coating easily cracks due to organic matter volatilization to further influence the combination firmness between the composite coating and a metal matrix, and the like are solved. The preparation method has the characteristics of being short in technological process, simple to control, stable and reliable in product quality, and the like, and the titanium dioxide-polyaniline composite corrosion-resistant coating prepared is suitable for being used as cathodic protection of copper, steel or stainless steel base material.

Owner:SHANDONG UNIV OF SCI & TECH

Seamless underwear shell fabric

InactiveCN102560848ASolve the problem of keeping warmSolve insulation problemsWeft knittingUndergarmentsYarnEngineering

The invention discloses a seamless underwear shell fabric, which is characterized by consisting of 35-40% of terylene, 57-61% of nylon and 3-4% of spandex, wherein the terylene has a hollow crisscrossed yarn structure. The seamless underwear shell fabric has the advantages of warm keeping, heat insulation, flatness, smoothness, comfortableness and excellent firmness and strength.

Owner:SHANGHAI GARMENT GRP IMP & EXP

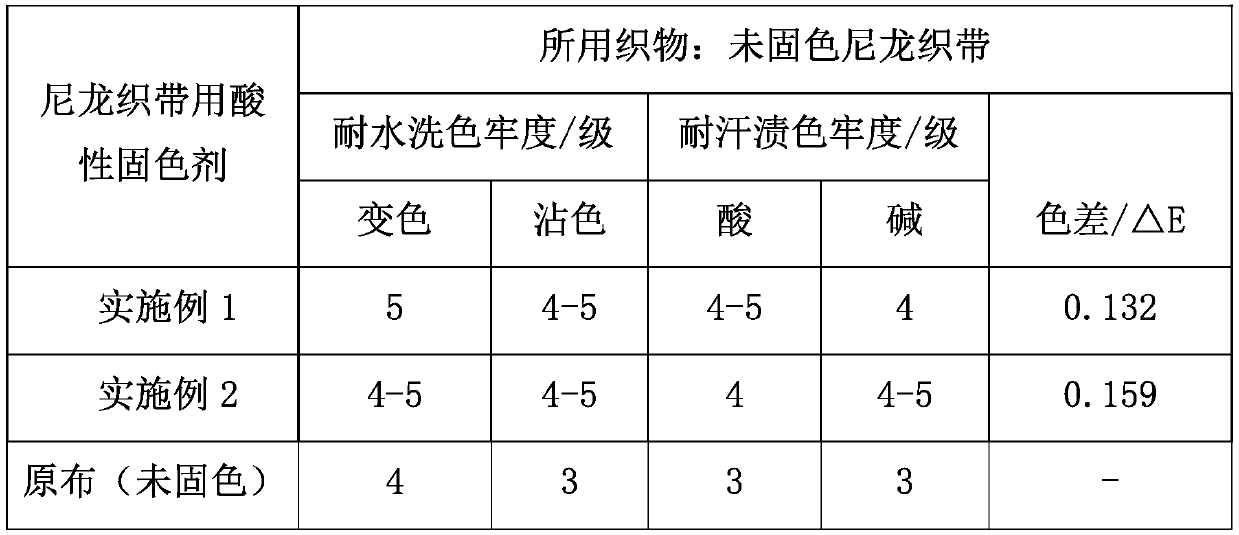

Acidic color fixing agent and preparation method and application method thereof

ActiveCN110685175AStrong anionicColor-fixing working solution is stableDyeing processColour fastnessAcetic acid

The invention relates to an acidic color fixing agent and a preparation method and application method thereof, wherein the acidic color fixing agent is prepared from, by mass, 40-50% of resin, 20-40%of glacial acetic acid, 2-8% of an activator, 5-20% of a solvent, 8-20% of a sulfonating agent, 10-30% of deionized water, and 3-5% of a stabilizer, wherein the acidic color fixing agent has the advantages that a color fixing working liquid is stable, agglomeration particles are avoided, the generation of color fixing spots in the color fixing process of a fabric can be avoided, the color change of the fabric after color fixing is reduced, and the color fastness to washing, the color fastness to perspiration and the like are improved.

Owner:苏州联胜化学有限公司

Textile printed ribbon

InactiveCN103660662AObtain anti-static (build-up) propertiesGet dryInk transfer from master sheetPolyurethane adhesiveSolvent

The invention discloses a textile printed ribbon. The textile printed ribbon comprises a base fabric and a coating on the surface of the base fabric, wherein the coating comprises a polyurethane adhesive layer clung to the upper surface of the base fabric and a polyurethane finishing layer on the upper surface of the base fabric, a polyurethane adhesive is prepared from a polyurethane emulsion, an antistatic agent, a thickening agent, a flatting agent and an auxiliary agent, and a polyurethane finishing agent is prepared from a solvent, polyurethane resin and an auxiliary agent. The textile printed ribbon disclosed by the invention has the characteristics that the polyurethane resin is used as a main ingredient of the coating, great adjustability of the mechanical properties of the polyurethane resin is utilized and the relevant functional auxiliaries are added for blending modification, so that the polyurethane barcode printed ribbon has the advantages of antistatic (accumulation) property, dry and wet friction resistance, blocking resistance and scratch resistance to the polyurethane coating film, as well as no toxicity, environmental friendliness, flexibility, elasticity and high heat stability.

Owner:孙光华

Textile product rubbing-resistant structural coloration ink and preparation method thereof

The invention provides a textile product rubbing-resistant structural coloration ink and a preparation method thereof. The preparation method of the textile product rubbing-resistant structural coloration ink combines reaction type photonic crystal microspheres and reaction type adhesives, so that during the later stage of self-assembly, photonic crystal can have bonding reaction with the adhesives to produce chemical bonds and further to improve the rubbing fastness of the photonic crystal and the base materials. The preparation method of the textile product rubbing-resistant structural coloration ink achieves grafting of photo-initiated reactive groups at the molecular level according to the characteristics of rigid gel microspheres and gel adhesives to greatly enhance intermolecular forces, thereby solving the problem of poor rubbing fastness and small coloration area of structural coloration textile products.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Preparation method of high-concentration high-color-fastness masterbatch for fibers

InactiveCN110483959AImprove floating silkImprove head breakPigment addition to spinning solutionMonocomponent polyesters artificial filamentFiberYarn

The invention discloses a preparation method of high-concentration high-color-fastness masterbatch for fibers. The method comprises the following steps: 1) weighing the following raw materials by weight: 8-30 parts of PET, 0-50 parts of PBT, 0-50 parts of pigment, 0.3-1.5 parts of a dispersing agent and 0.5-1.2 parts of a rheology modifier, with the intrinsic viscosity of PET being 0.66-0.82 dL / gand the intrinsic viscosity of the PBT being 0.82-1.0 dL / g; (2) after the raw materials are weighed according to the proportion, adding the weighed raw materials into a mixer, stirring the materials for 10 minutes to fully mix the materials, then extruding the uniformly mixed materials in a double-screw extruder, and carrying out water-cooling, strip drawing and pelletizing to obtain the masterbatch. The double-screw extruder is provided with a vacuumizing device. The masterbatch prepared by the invention is suitable for high-color-fastness PET fibers, can solve the problems of poor thermal migration resistance, poor washing fastness and spinnability of the existing colored fibers before spinning, improves the phenomena of yarn drifting and end breaking in the fiber preparation process, and is beneficial to prolonging the service cycle of a spinning assembly.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

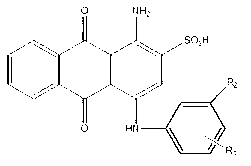

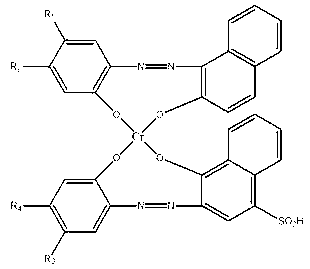

Acid dye composition for nylon dyeing

ActiveCN102702787ASolve both bright color and lightSolve the fastnessOrganic dyesDyeing processColored lightAcid dye

The invention discloses an acid dye composition for nylon dyeing. The acid dye composition for nylon dyeing comprises a dye component and an auxiliary component. The acid dye composition is applicable to dyeing of nylon fabrics. The problems that metal complex dye has dark colored light in nylon fabric dyeing and other dyes have poor wet fastness are solved. The acid dye composition for nylon dyeing has high wet fastness and bright colored light and can meet requirements of medium- and high-grade clothing fabric products on quality specification.

Owner:HEJIAN YINGZHOU CHEM IND CO LTD

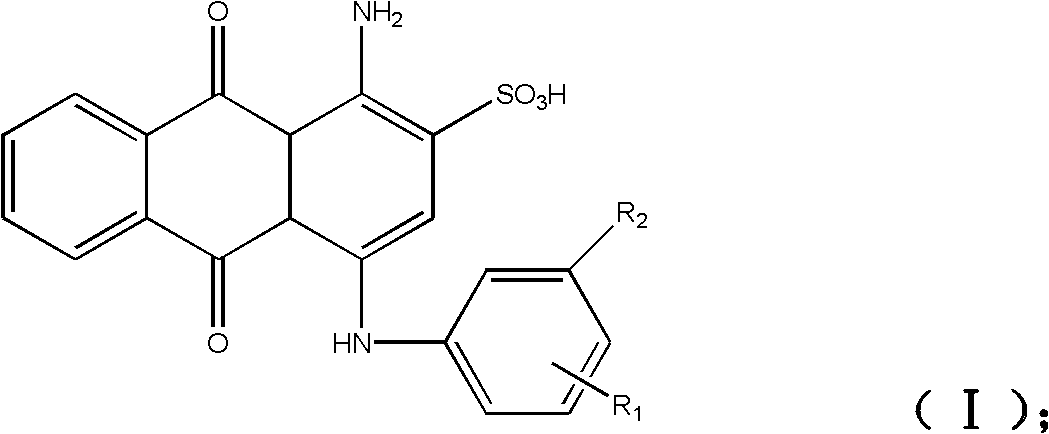

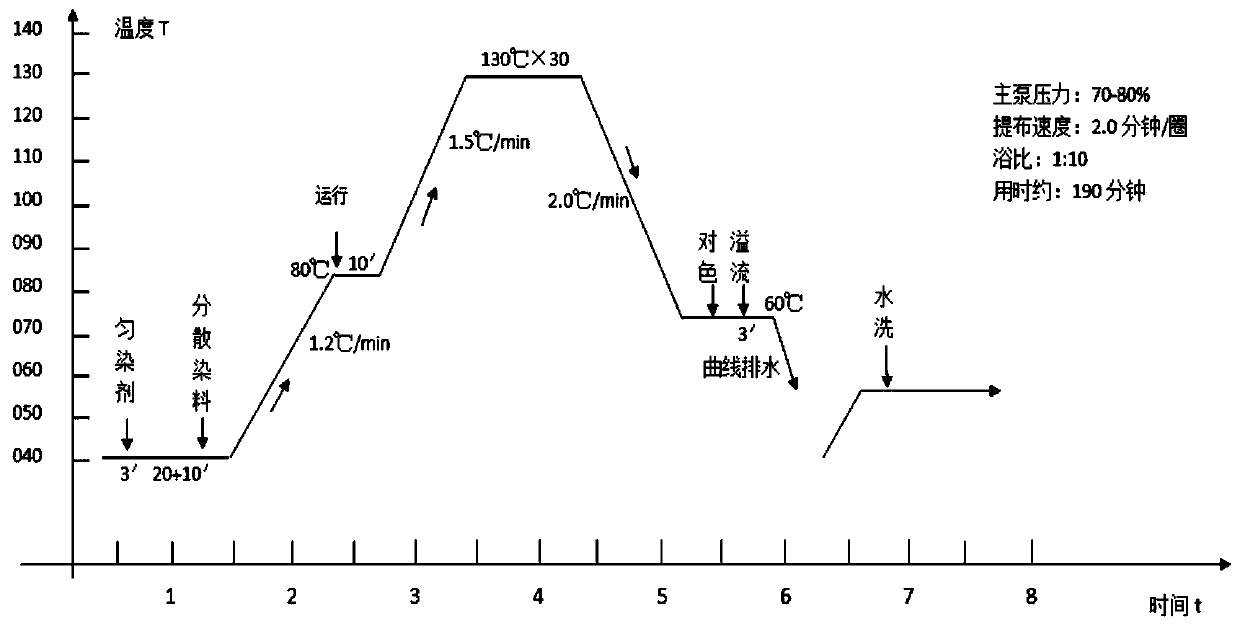

Dye and method for dyeing and finishing polyester fabric by using same

The invention discloses a dye comprising the following raw materials: 0.8%owf of disperse dye FW-N violet, 0.5 g / L of HAC, 0.5 g / L of dispersing and leveling agent, 1.5 g / L of moisture absorbing, sweet releasing and dirt repelling agent FC226, 1.0 g / L of degreasing agent, 3.0 g / L of acidic reduction cleaning agent and 10 g / L of uvioresistant shielding agent. The invention further discloses a method for dyeing and finishing a polyester fabric by using the dye, and the method comprises the steps such as embryo setting, dyeing and finished product setting. The method has the following beneficialeffects that (1) the relevant fastness of the fabric treated by using the disperse dye FW-N violet is improved, so that the problems of relevant fastness and brightness caused by dye character in workshop production are solved; and (2) the fabric achieves moisture absorbing, sweet releasing and dirt repelling functions after being treated by using the moisture absorbing, sweet releasing and dirt repelling agent FC-226.

Owner:福建信泰印染有限公司

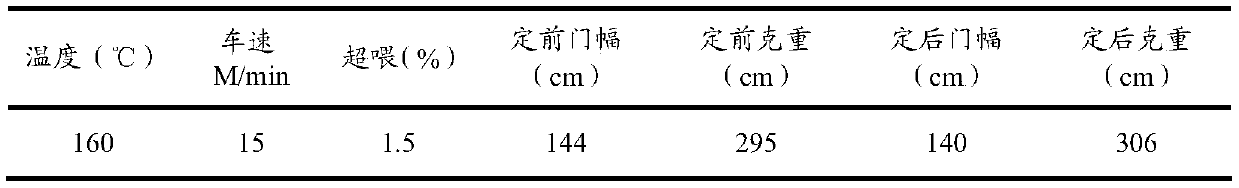

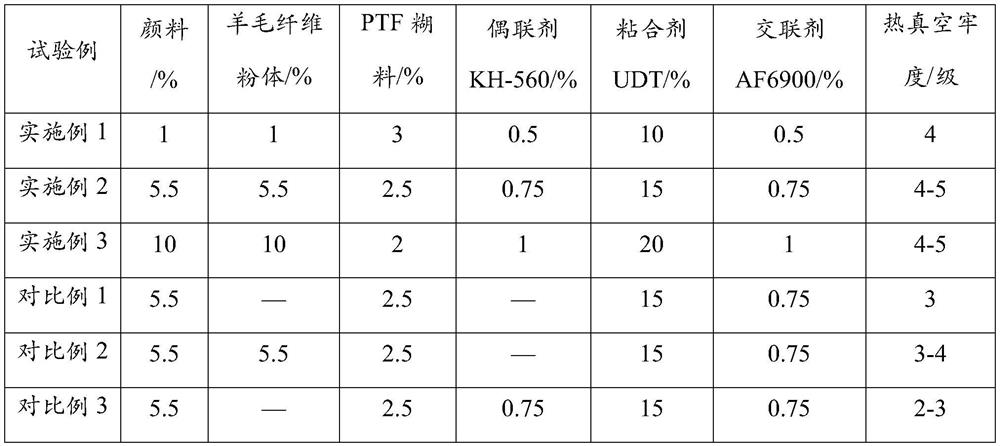

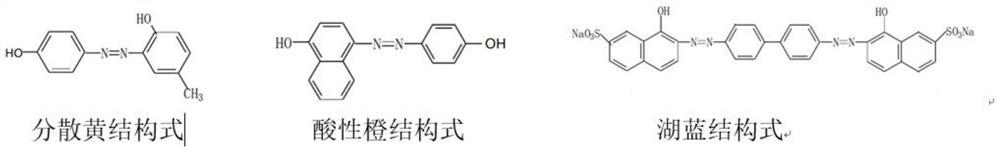

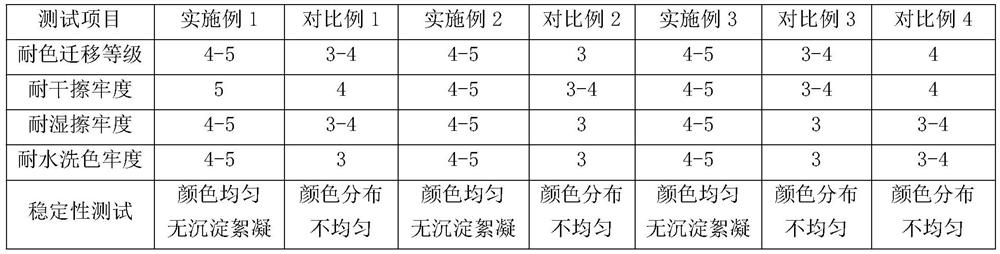

High-thermal-vacuum-fastness pigment printing process

ActiveCN113529441AHigh heat vacuum fastness improvementImproved thermal vacuum fastnessDyeing processTextile printerColour fastness

The invention provides a high-thermal-vacuum-fastness pigment printing process. The pigment printing process comprises printing treatment of pigment printing paste and padding treatment of waterborne polyurethane emulsion. The pigment printing paste comprises the following components in percentage by mass of 1%-10% of pigment, 1%-10% of wool fiber powder, 0.5%-1% of a silane coupling agent KH-560, 10%-20% of an adhesive, 2%-3% of a thickening agent, 0.5%-1% of a cross-linking agent and the balance of a solvent. According to the invention, the wool fiber powder with a special structure and the coupling agent are added into the color paste, and a layer of waterborne polyurethane coating film is padded after printing, so that the high thermal vacuum fastness of pigment molecules is remarkably improved, and the problems of pigment sublimation and color fastness migration caused by thermal vacuum suction of pigment molecules of a colored textile under the conditions of high vacuum degree and high-temperature environment are solved.

Owner:WUHAN TEXTILE UNIV

Colored waterborne polyurethane and preparation method thereof

PendingCN113501927AImprove reaction efficiencyImprove utilization efficiencyTextiles and paperPolymer sciencePolyol

The invention discloses colored waterborne polyurethane which is prepared from the following raw materials in parts by weight: 50-200 parts of diisocyanate, 150-350 parts of conventional dihydric alcohol, 50-120 parts of colored polyester polyol, 1-20 parts of micromolecule chain extender, 10-45 parts of hydrophilic chain extender and 400-1200 parts of deionized water. The colored polyester polyol is prepared from the following raw materials in parts by weight: 20-100 parts of binary acid, 30-110 parts of a micromolecular chain extender, 5-20 parts of dye containing active hydroxyl and 0.1-0.5 part of tetrabutyl titanate, wherein the mole number of hydroxyl to carboxyl is (1.1-1.3): 1. According to the colored waterborne polyurethane, the colored group is synthesized into a polyurethane molecular chain in situ through a chemical reaction, and the dye is combined with polyurethane through a chemical bond, so that the defects of color migration, low rubbing fastness and low water fastness are overcome; meanwhile, the dye and the polyurethane are in the same molecular structure and belong to a system, so that the stability is higher, and the flooding phenomenon is avoided. When being applied to the microfiber leather, the colored waterborne polyurethane has higher color fastness to washing, color fastness to rubbing and color migration resistance levels.

Owner:明新梅诺卡(江苏)新材料有限公司

Preparation method of high-concentration colored antibacterial master batch for fibers

InactiveCN110628186ASolve heat resistanceSolve the fastnessPigment addition to spinning solutionChemistryHigh concentration

The invention discloses a preparation method of a high-concentration colored antibacterial master batch for fibers. The method comprises the following steps: 1) taking the following raw materials in parts by weight: 8-30 parts of PET, 0-50 parts of PBT, 0-50 parts of a pigment, 0.5-15 parts of antibacterial powder, 0.3-1.5 parts of a dispersing agent and 0.5-1.2 parts of a rheology modifier, wherein the intrinsic viscosity of PET ranges from 0.66 dL / g to 0.82 dL / g, and the intrinsic viscosity of PBT ranges from 0.82 dL / g to 1.0 dL / g; and 2) weighing the raw materials according to the proportion, adding the weighed raw materials into a mixer, stirring for 10 minutes, fully stirring and uniformly mixing the raw materials, then putting the uniformly mixed materials into a double-screw extruder, and carrying out extrusion granulation, wherein the double-screw extruder is provided with a vacuumizing device. The master batch prepared by the method is suitable for colored antibacterial PET fibers, effectively solves the problems of poor thermal migration resistance, poor washing fastness and spinnability of conventional colored fibers before spinning, reduces filament drifting and end breaking, and prolongs the service life of a spinning assembly.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com