Fluorine-silicon-modified acrylate adhesive, preparation method and application thereof

An acrylate, fluorosilicon modified technology, used in ester copolymer adhesives, adhesive types, graft polymer adhesives, etc. , to achieve the effect of soft hand feeling, solving the contradiction between hand feeling and fastness, easy to implement and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Dissolve 0.3 grams of emulsifier sodium dodecyl sulfate (SDS) in 50 grams of deionized water and stir at high speed (1000r / min) for 10 minutes, mix well, and make a pre-emulsion;

[0058] (2) Mix 6 grams of butyl acrylate, 2.5 grams of methyl methacrylate, 0.6 grams of hydroxyethyl acrylate, 0.6 grams of isooctyl acrylate, 0.9 grams of glycidyl methacrylate, 0.4 grams of acrylic acid, 1.5 grams of fluorine-containing organic Silicon monomer (formula I structure, average degree of polymerization n is 8, synthesized by existing anionic polymerization method), 0.6 g of n-hexadecane and 0.15 g of azobisisobutyronitrile, mixed evenly and slowly added dropwise to the pre- In the emulsion, the dropping time is 5 minutes, stirred at high speed (1000r / min) for 20 minutes, and then treated with an ultrasonic pulverizer in an ice-water bath for 8 minutes to obtain a fine emulsion;

[0059] (3) Pour the above fine emulsion into a four-necked flask equipped with a stirring paddl...

Embodiment 2

[0067] (1) Dissolve 0.3 grams of emulsifier sodium dodecyl sulfate (SDS) in 50 grams of deionized water and stir at high speed (1000r / min) for 10 minutes, mix well, and make a pre-emulsion;

[0068] (2) Mix 6 grams of butyl acrylate, 2.5 grams of methyl methacrylate, 0.6 grams of hydroxyethyl acrylate, 0.6 grams of isooctyl acrylate, 0.9 grams of glycidyl methacrylate, 0.4 grams of acrylic acid, 1.5 grams of fluorine-containing organic Silicon monomer (formula I structure, average degree of polymerization n is 16, synthesized by existing anionic polymerization method), 0.6 g of n-hexadecane and 0.15 g of ammonium persulfate, mixed evenly and slowly added dropwise to the emulsifier aqueous solution , the dropping time is 5 minutes, stirred at high speed (1000r / min) for 20 minutes, and then treated with an ultrasonic pulverizer in an ice-water bath for 8 minutes to obtain a fine emulsion;

[0069] (3) Pour the above fine emulsion into a four-necked flask equipped with a stirring...

Embodiment 3

[0074] (1) Dissolve 0.3 grams of emulsifier sodium dodecyl sulfate (SDS) in 50 grams of deionized water and stir at high speed (1000r / min) for 10 minutes, mix well, and make a pre-emulsion;

[0075] (2) 7 grams of butyl acrylate, 2.5 grams of methyl methacrylate, 1 gram of glycidyl methacrylate, 0.8 grams of acrylic acid, 1.5 grams of fluorine-containing silicone monomer (formula I structure, average degree of polymerization n is 32 , synthesized by the existing anionic polymerization method), 0.6 g of n-hexadecane and 0.15 g of azobisisobutyronitrile, after mixing evenly, slowly drop them into the emulsifier aqueous solution, the dropping time is 5min, at high speed (1000r / min) stirring for 20 minutes, and then treated with an ultrasonic pulverizer in an ice-water bath for 8 minutes to obtain a fine emulsion;

[0076] (3) Pour the above fine emulsion into a four-necked flask equipped with a stirring paddle, a thermometer and a condenser tube, pass high-purity nitrogen for 30...

PUM

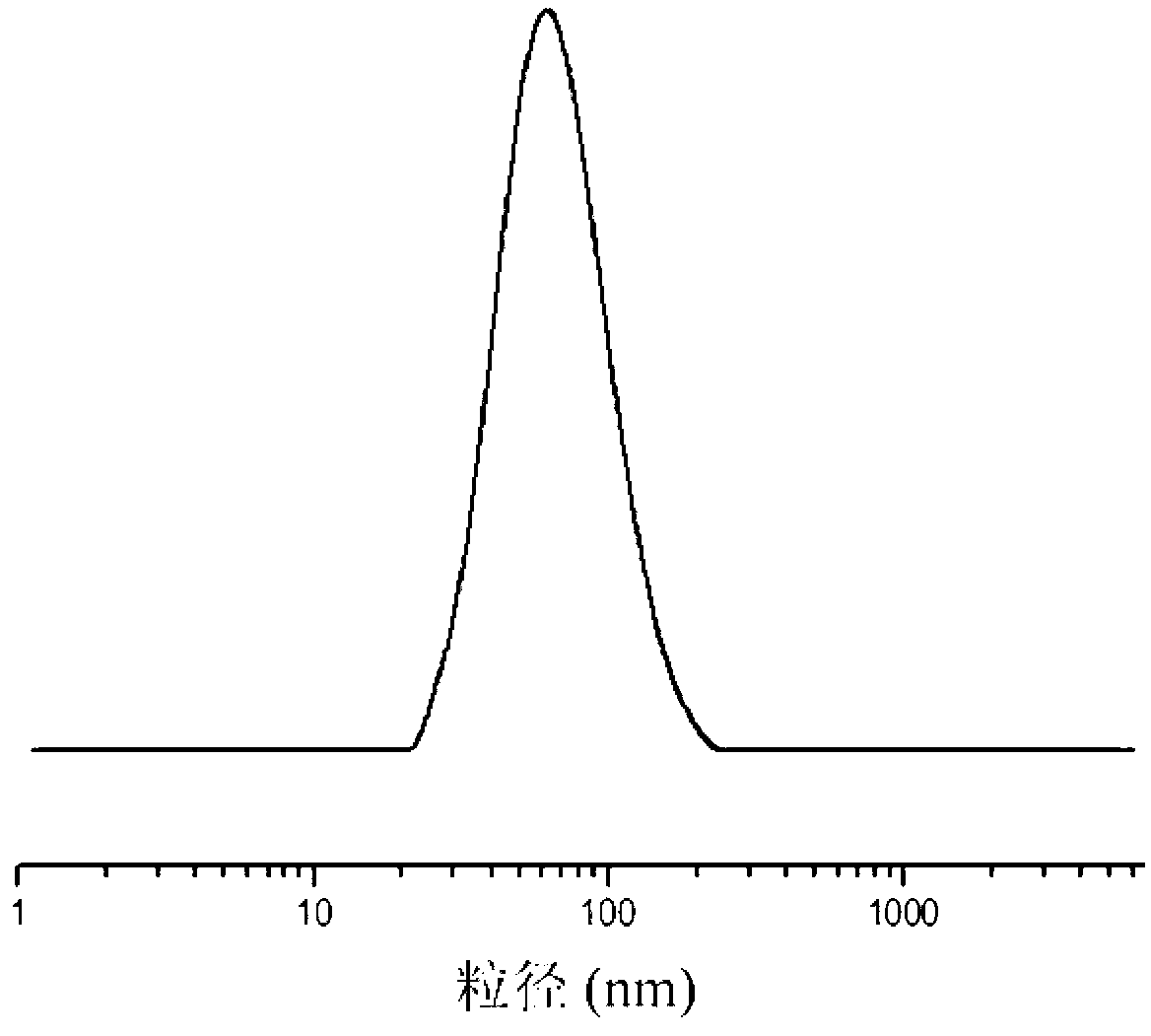

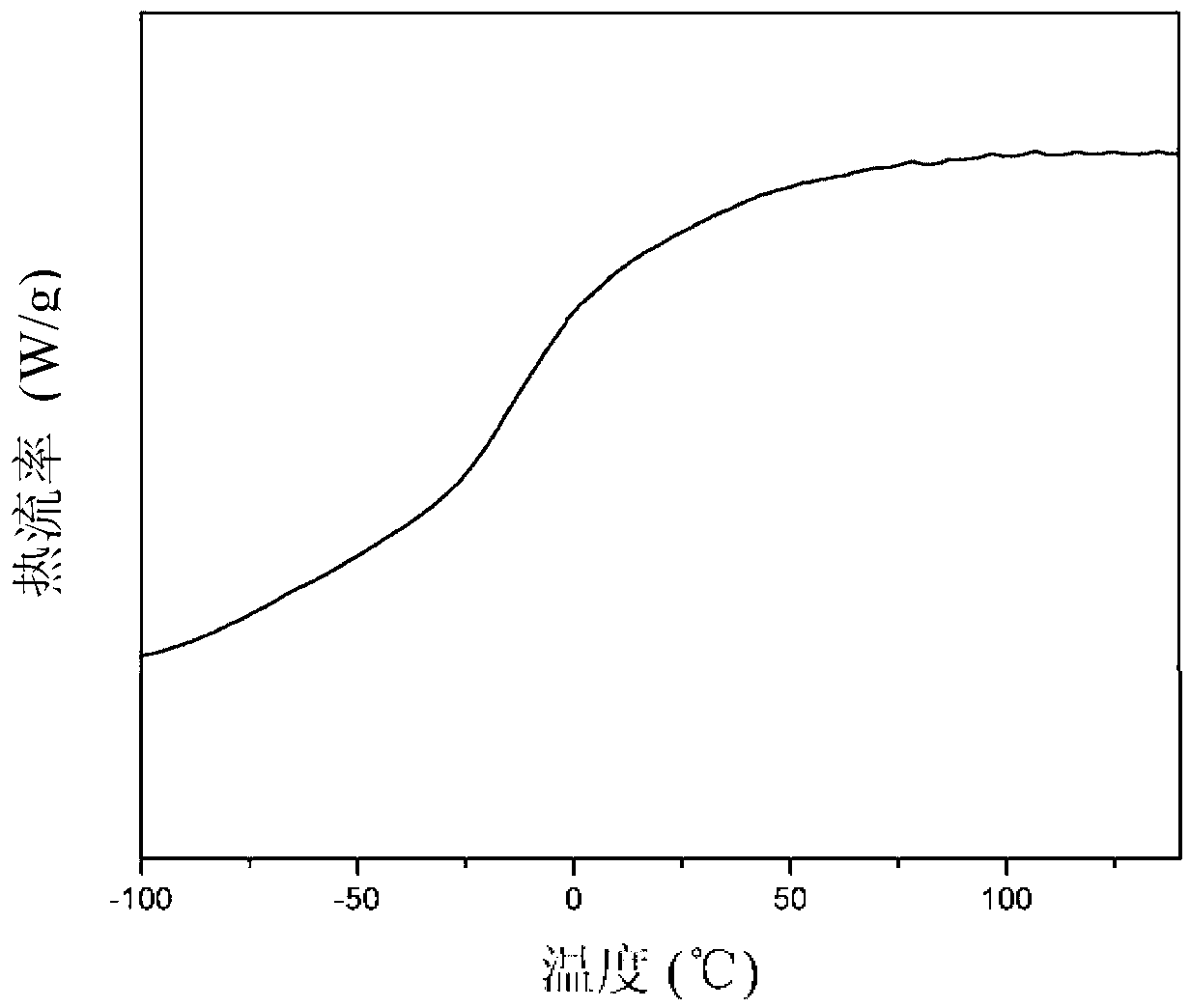

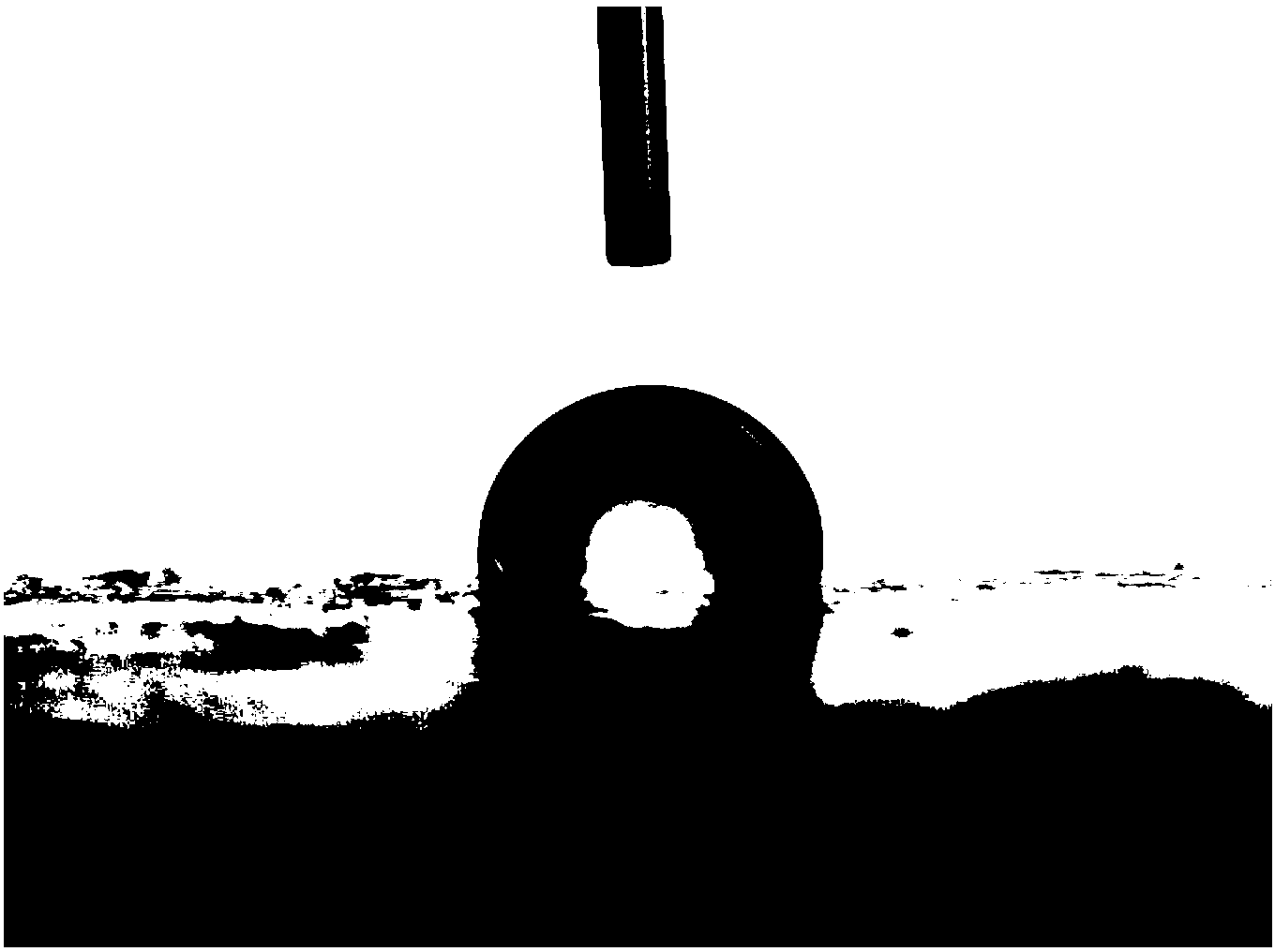

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com