Patents

Literature

39 results about "Fiber Chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemistry concerned with the composition, structure, and properties of natural and manufactured fibrous materials.

One-time use composite tool formed of fibers and a biodegradable resin

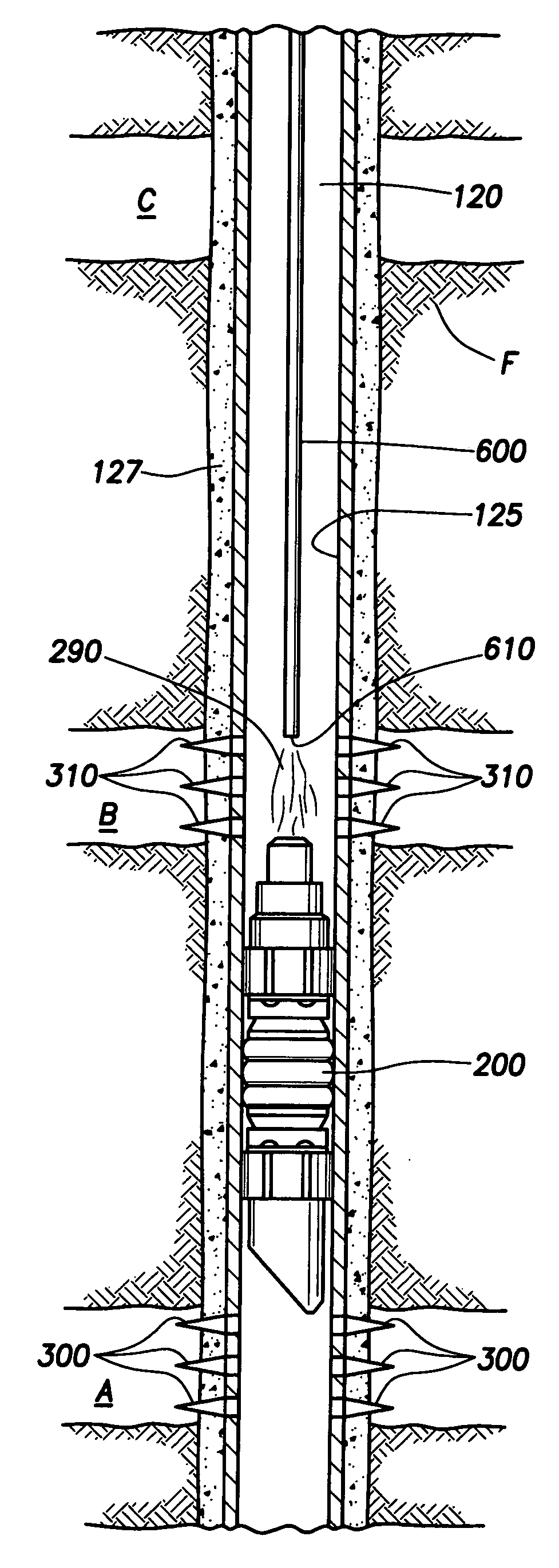

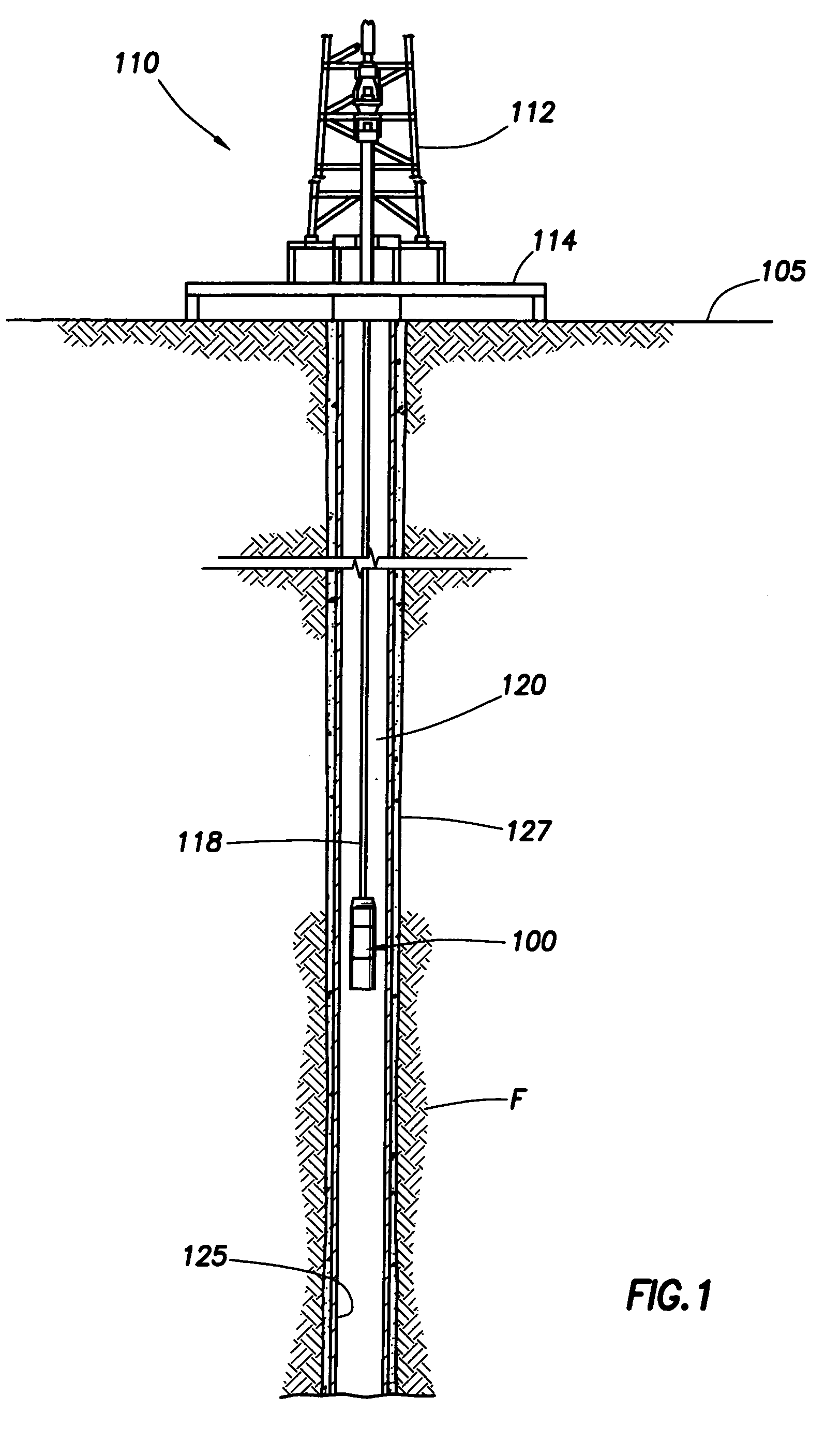

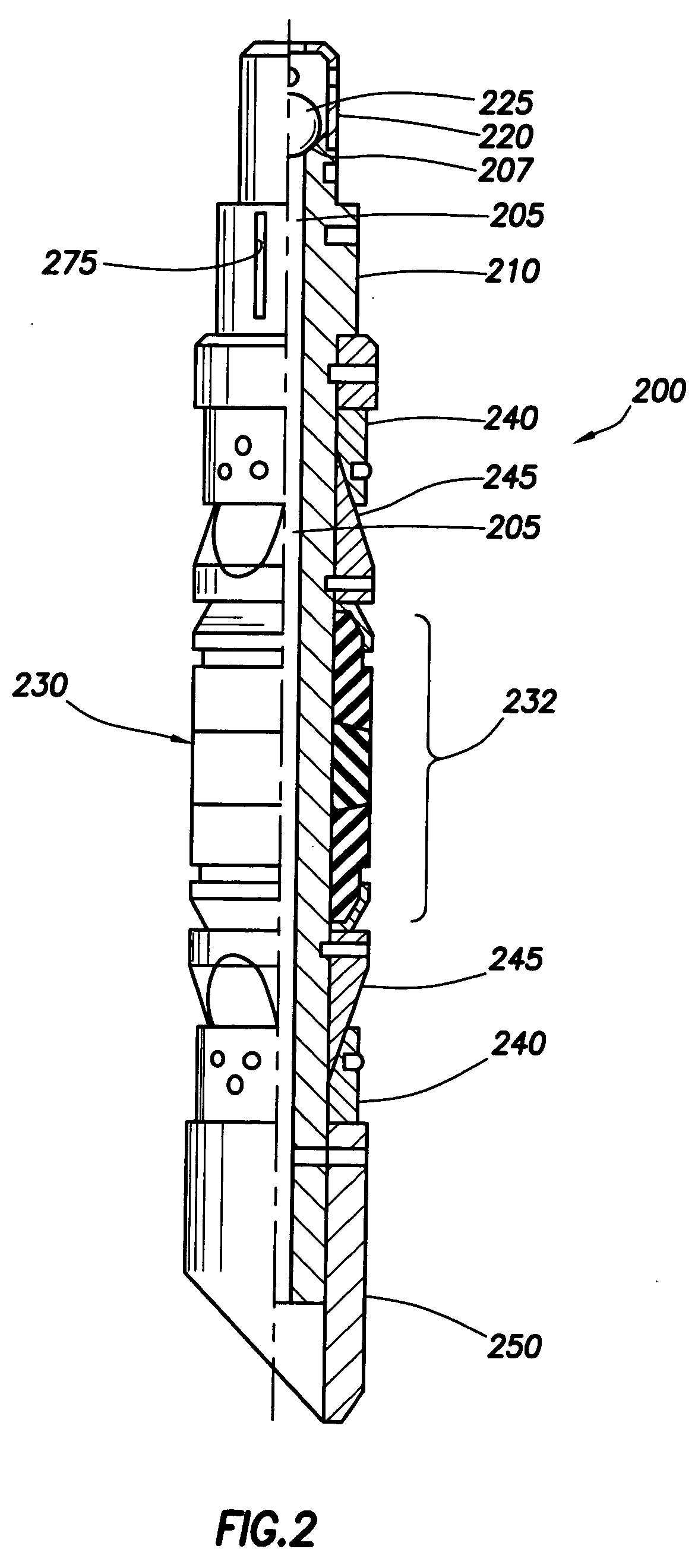

ActiveUS20050205265A1Eliminates and at least minimizes drawbackFluid removalWell/borehole valve arrangementsLactideFiber Chemistry

The present invention is directed to disposable composite downhole tool formed of a resin-coated fiber. The fiber is formed of a degradable polymer, such as a poly(lactide) or polyanhydride. The resin is formed of the same degradable polymer as the fiber. It chemically bonds to the fiber, thereby making a strong rigid structure once cured. The fiber may be formed into a fabric before being coated with the resin. Alternatively, the fiber is formed of a non-biodegradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Enhanced ballistic performance of polymer fibers

ActiveUS7964518B1Synthetic resin layered productsPersonal protection gearFiber ChemistryPhysical strength

Ballistic resistant materials having improved strength and lighter weights. More particularly, improved ballistic resistant fabrics produced from drawn, high modulus fibers having a reduced fiber diameter and improved physical strength properties, without changing other properties such as fiber chemistry, binder resin type and binder resin content. The fabrics incorporate low denier per filament monofilament fibers, low denier per filament multifilament fibers, or a combination of low denier per filament monofilament fibers and low denier per filament multifilament fibers in a specialized fabric construction to form fine fiber layers and fabrics having enhanced strength and fiber areal density without altering the fabric weight, or having reduced fabric weight without a corresponding reduction in ballistic performance.

Owner:HONEYWELL INT INC

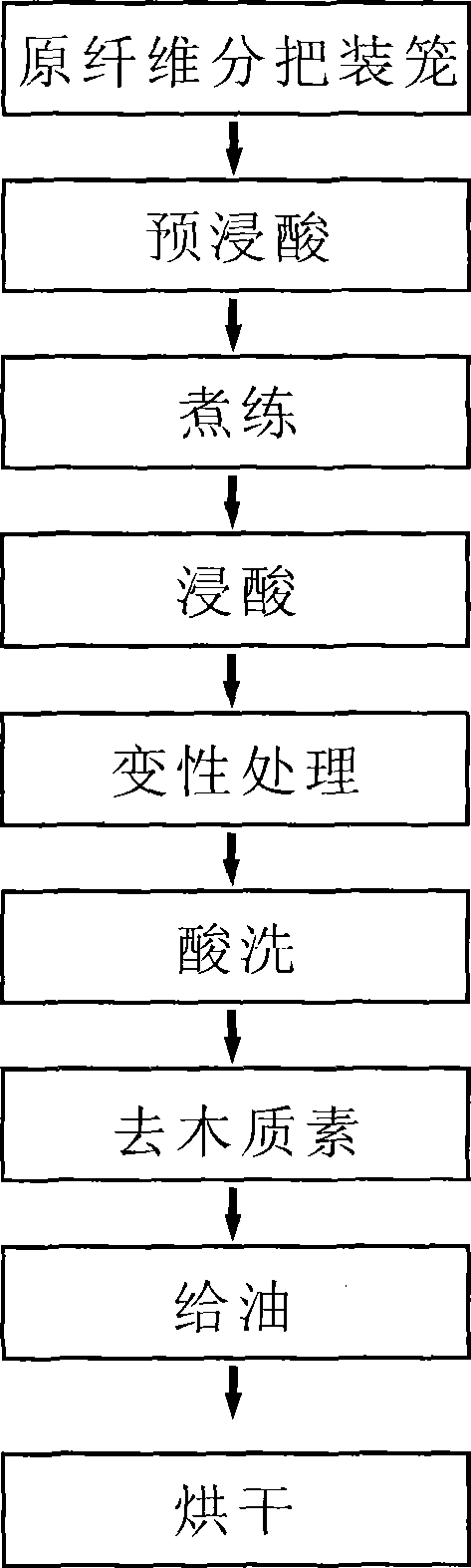

Chemical degumming technique for pineapple leaf fiber

InactiveCN101503828AHigh capillary penetrationImprove fiber finenessFibre treatment to obtain bast fibreCelluloseYarn

The invention discloses an ananas hemp chemical degumming process. The process is characterized in that: the process comprises the following steps of ananas hemp piecing out and caging, pre-pickling, boiling, washing, pickling, denaturation, acid washing, washing, lignin removal, washing, greasing and drying procedures. The boiling comprises the following steps: adding the fibril into a 30 percent mixed liquor which is prepared from liquid alkali, trisodium phosphate and water glass and has a weight 15 to 17 folds of that of the fibril, keeping the pressure of 0.1 to 0.15 MPa for 4 to 4.5 hours, and taking out the fibril and washing the fibril by water. The mixed liquor used for boiling the fibril comprises 10 to 12 g / L of the liquid alkali, 0.4 to 0.6 g / L of the trisodium phosphate and 2 to 2.5 g / L of the water glass. The liquid alkali boiling eliminates non-cellulose substances in the ananas hemp, and makes the ananas hemp have a high capillary penetration action. The fiber molecules have relatively uniform lengths; the fiber fineness is high and reaches 550 yarns; and therefore the ananas hemp is suitable for spinning.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

Method for chemical modification, pigment dyeing and overflow sand washing of fiber

InactiveCN101736579AEmbody noveltyEmbody creativityBiochemical fibre treatmentDry-cleaning apparatus for textilesFiber ChemistryCellulose fiber

The inventions discloses a method for chemical modification, pigment dyeing and overflow sand wash of a fiber and application thereof to garment dyeing. The method comprises the following steps of: carrying out an anode chemical modification reaction on a cellulosic fiber of a fiber product by using a cation denaturing agent under the non-alkali condition of a fiber product; and then carrying out pigment dyeing and overflow sand wash treatment to enable the fiber product to form the traditional stone washing old-coped effect. Compared with the traditional processing technology, the invention has the advantages that: the hand feeling and the firmness of the products can be improved by modifying the fiber for pigment dyeing, and meanwhile, the technology can be simplified, the process can be shortened, and the consumption and the pollution can be reduced. The invention solves the quality problems on the hand feeling, the firmness, the color reproducibility and the like in traditional garment stone milling treatment.

Owner:鞍山博亿印染有限责任公司

Enhanced ballistic performance of polymer fibers

ActiveCN102933758ASynthetic resin layered productsPersonal protection gearPolymer scienceSingle fibre

Ballistic resistant materials having improved strength and lighter weights. More particularly, improved ballistic resistant fabrics produced from drawn, high modulus fibers having a reduced fiber diameter and improved physical strength properties, without changing other properties such as fiber chemistry, binder resin type and binder resin content. The fabrics incorporate low denier per filament monofilament fibers, low denier per filament multifilament fibers, or a combination of low denier per filament monofilament fibers and low denier per filament multifilament fibers in a specialized fabric construction to form fine fiber layers and fabrics having enhanced strength and fiber areal density without altering the fabric weight, or having reduced fabric weight without a corresponding reduction in ballistic performance.

Owner:HONEYWELL INT INC

Method for improving hydrophobicity and stability of wood based on nanometer titania

ActiveCN106863507AAvoid enteringImprove smoothnessWood treatment detailsPretreatment apparatusCelluloseMicro nano

The invention discloses a method for improving hydrophobicity and stability of wood based on nanometer titania. Low-viscosity urea resin, nano graphene and nanometer titania serve as materials, a micron-order rough texture structure of the wood is combined, a film of a micro-nano second-level concave-convex rough texture structure is established on the surface of the wood through a sol-gel method, lyophobic substances are modified on the film of the micro-nano second-level concave-convex rough texture structure, and a layer of lyophobic film is attached to the surface of the wood. The method has the beneficial effects that wood cell cavities are filled with the low-viscosity urea resin so that water inflow can be prevented; meanwhile, a fiber chemical group of the wood and the urea resin are subjected to the chemical reaction, cellulose framework chemical bonds are mutually combined, and firmness between the urea resin and the wood is enhanced; and by utilization of nanometer titania particles and the micron-order rough structure of the wood, a second-level convex-concave rough film structure simulating the surface of a lotus leaf is prepared, and the purpose of preventing water inflow is achieved.

Owner:A ZENITH HOME FURNISHINGS CO LTD

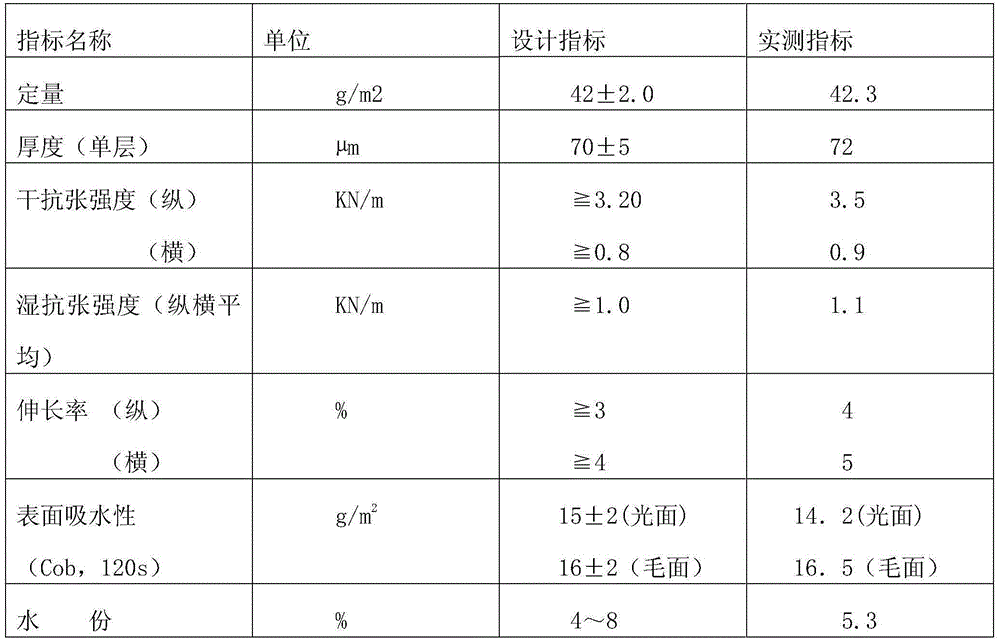

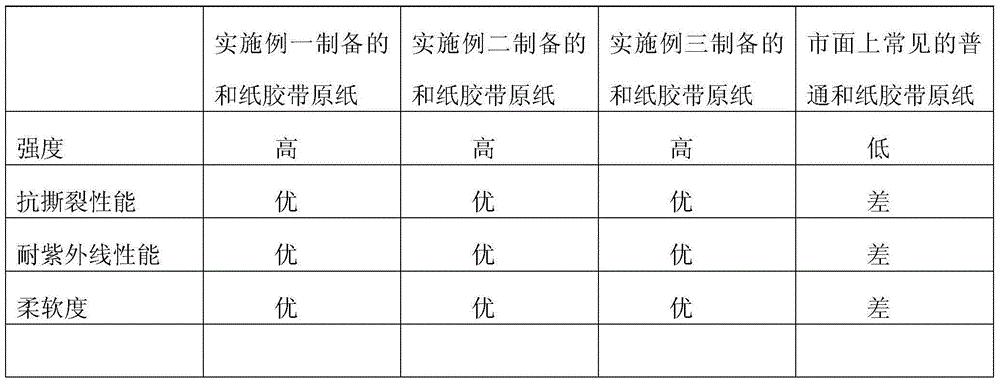

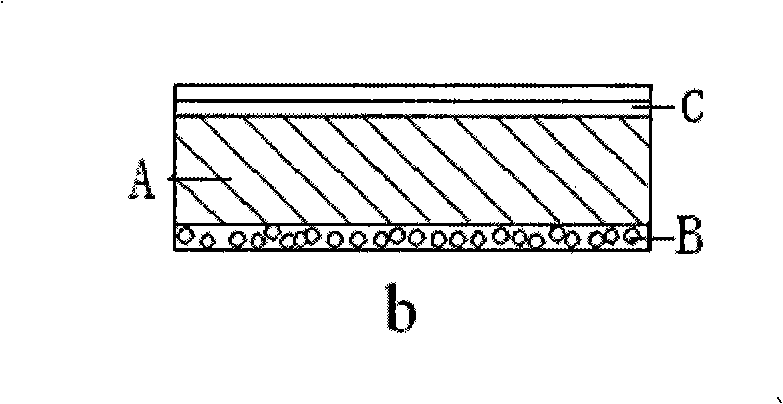

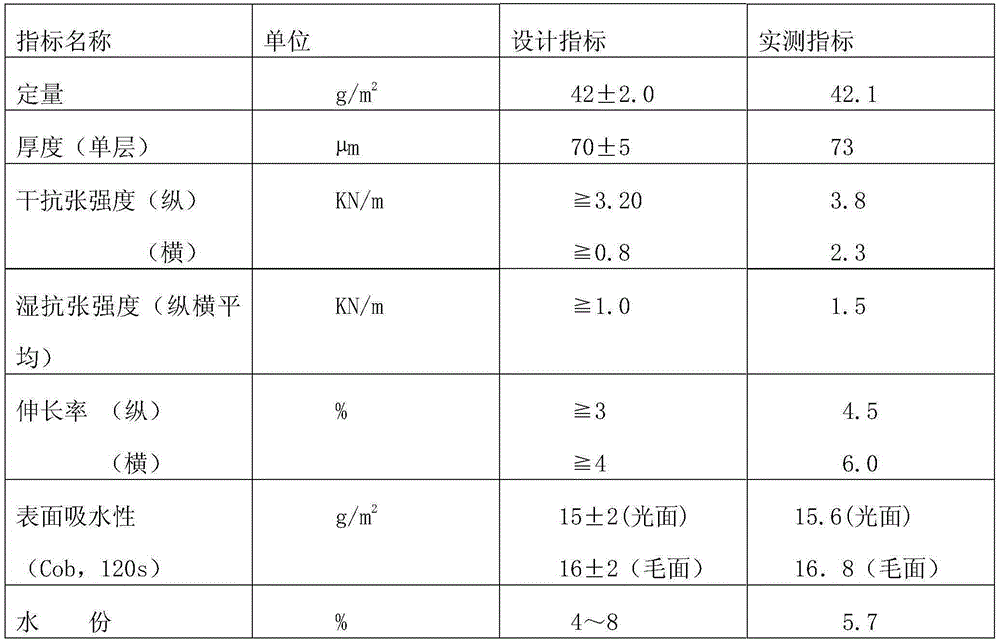

Body paper of washi adhesive tape and production method for body paper

ActiveCN105155329AExtended service lifeImproves UV resistanceVegetable material additionPaper coatingFiberUltraviolet

The invention relates to body paper of a washi adhesive tape. By taking long fiber wood pulp, short fiber chemical and mechanical pulp, a wet strength agent, coating latex and a golden cypress extraction solution as raw materials, the body paper of the washi adhesive tape is prepared by the steps of pulping treatment, addition of auxiliaries, supercooling treatment, papermaking treatment, coating treatment and paper forming. The body paper provided by the invention has the beneficial effects that the body paper has good dry and wet strength and delamination resisting strength, and good tear resistance, can satisfy the strength demands in subsequent processing and actual use, is not layered, and has good flexibility; the body paper has good water resistance and solvent resistance and excellent ultraviolet resistance and temperature resistance, and can be used for reducing aging of the washi adhesive tape and prolonging the service life of washi adhesive tape; the body paper has good surface smoothness, so that production and processing of the adhesive tape are facilitated.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

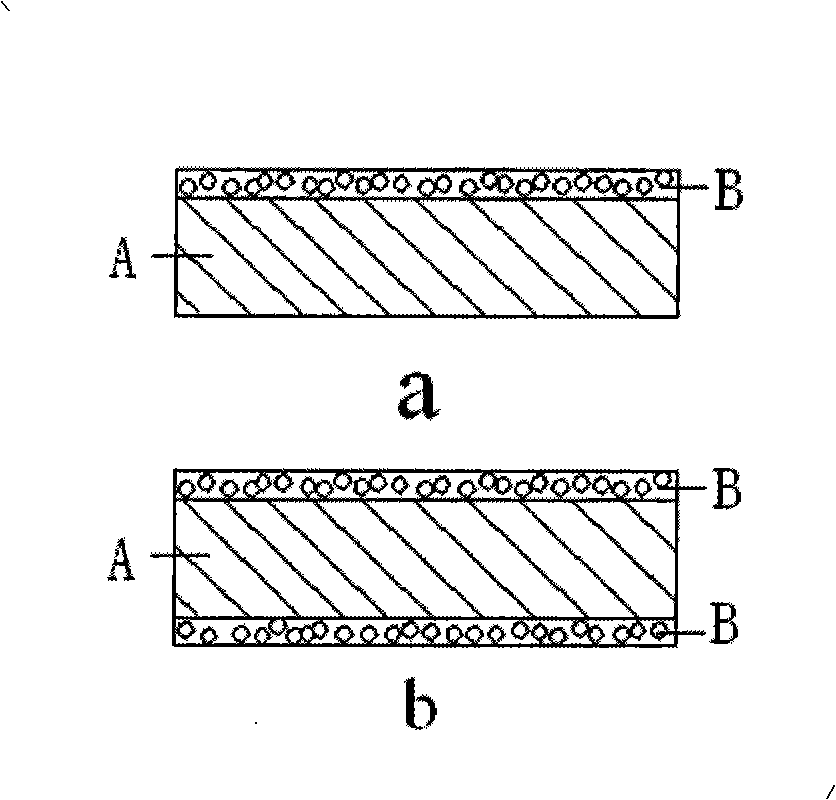

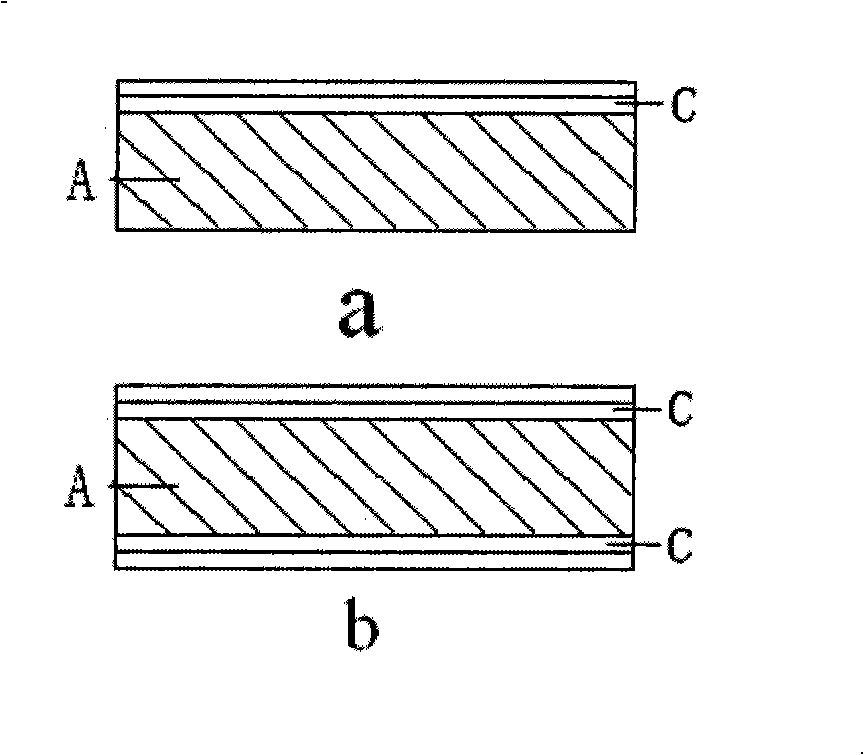

Acetate fiber coating paper and paper filter stick for preparing cigarette filter stick and preparing method thereof

InactiveCN101408014AImproving sensory evaluation smoking qualityReduce tarTobacco smoke filtersPaper coatingPlant fibreCellulose acetate

The invention relates to special paper which uses acetate fiber to carry out coating, a preparation method thereof, and a corresponding paper filter stick, belonging to the preparation technical field of a cigarette filter. The special paper containing the acetate fiber coating is made by that the paper which is made by one or a plurality of plant fiber, synthetic fiber, chemical fiber or other modified fiber is adopted as the base paper, and the acetate fiber coating is carried out on one surface or two surfaces of the base paper. The paper filter stick is made by a cigarette holder forming machine by adopting the paper made after the acetate fiber coating as the raw material. The invention not only reduces the use amount of acetate fiber or cellulose acetate so as to reduce cost, but also remarkably improves the aesthetic quality of the paper filter stick cigarette.

Owner:CHINA TOBACCO HUNAN INDAL CORP

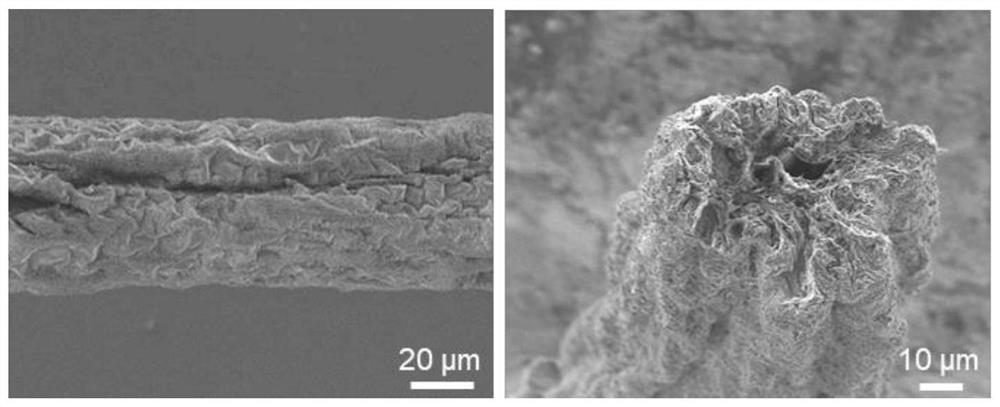

Method for surface modification by carbon fiber chemical nickel-plating

InactiveCN112144272AChange the microstructureImprove bindingCarbon fibresLiquid/solution decomposition chemical coatingCarbon fibersO-Phosphoric Acid

The invention belongs to the technical field of fiber material surface modification, and particularly relates to a method for surface modification by carbon fiber chemical nickel-plating. The method comprises the following steps: degumming, coarsening, sensitizing and activating. Firstly, glue on the surfaces of carbon fibers is removed through high-temperature firing, then the treated carbon fibers are soaked in a mixed solution of hydrofluoric acid and concentrated phosphoric acid, the microstructure of the surfaces of the carbon fibers is changed, the binding force between metal plating layers is increased, and then the coarsened carbon fibers are soaked in SnCl2, so that a layer of substance having good reducibility is attached to the surfaces of the carbon fibers; and firstly, the sensitized carbon fibers are soaked in an activating solution consisting of palladium chloride, ammonium chloride and sodium hypophosphite to form a layer of noble metal elementary substance on the carbon fibers, and finally, nickel plating treatment is performed on the activated carbon fibers, so that the modified carbon fibers have good wettability, and a nickel plating layer can be more uniform, compact and high in adhesive force.

Owner:TIANJIN POLYTECHNIC UNIV

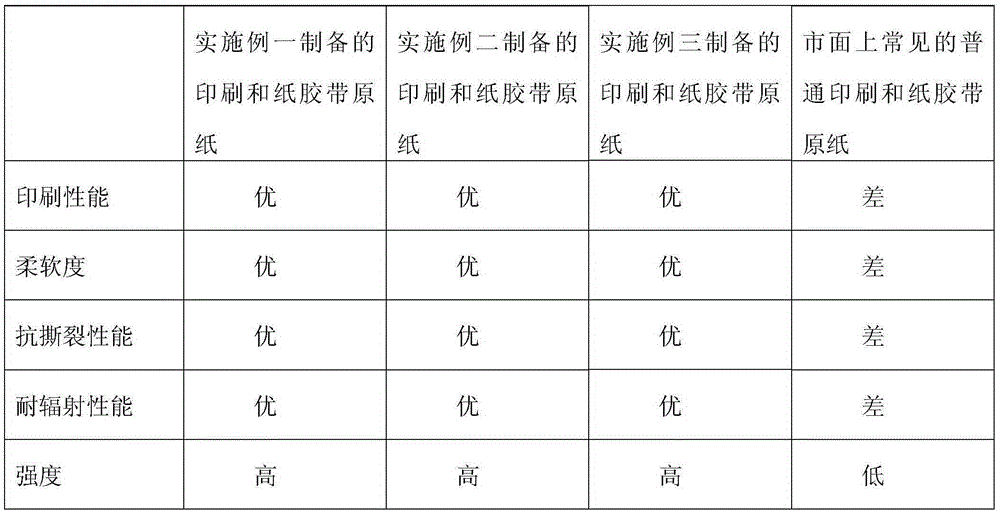

Raw paper for printing Japanese paper adhesive tape and production method of same

ActiveCN105239447AGood surface smoothnessImprove toughnessPaper coatingReinforcing agents additionFiberPaper adhesive tape

Raw paper for printing Japanese paper adhesive tapes is prepared from following raw materials: long-fiber wood pulp, short-fiber chemical mechanical wood pulp, bamboo pulp, a filling material, a wet-strength agent, coating latex and an extract liquid of cactus. The raw paper is prepared through the steps of performing pulping treatment, adding additives to the pulp, supercooling the pulp, performing papermaking, coating the paper, drying the paper and performing press polish and cutting to obtain the raw paper. The raw paper for printing Japanese paper adhesive tapes has excellent surface flatness, high printing clearness, good printing effect, excellent softness, excellent dry and wet strengths, excellent delamination resistance strength and anti-tear performance, excellent water- and solvent-resistant performances and excellent anti-radiation performance and temperature resistance. The method can reduce aging in the raw paper for printing Japanese paper adhesive tapes and prolonging the service life of the raw paper for printing Japanese paper adhesive tapes.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

Method for preparing persistent inhibition carbon fiber dressing

ActiveCN104611786ASilver loading is firmImprove bindingFibre treatmentLiquid/solution decomposition chemical coatingActivated carbonHigh volume manufacturing

The invention relates to a method for preparing activated carbon fiber medical dressing. The method specifically comprises the following steps: (1) carrying out pretreatments on a clean raw material fiber, such as deoiling, roughening and activating, and cleaning the clean raw material fiber; (2) chemically silvering the fiber, and supplementing related consumed functional components in the plating solution after the plating operation; (3) washing, dewatering and drying the silver-loaded fiber; (4) pre-treating, carbonizing and activating the silver-loaded fiber. The method is simple in process and principle, the used chemical silvering solution is stable and is suitable for mass production, and granules in the prepared silver-loaded carbon fiber material are firm in binding force with the matrix, moderate in mechanical strength, excellent in antibacterial ability and continuous in stability, so that the silver-loaded carbon fiber material has a broad application prospect in the healthcare industry.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Preparation method for continuous fiber copper pipe

InactiveCN105671529AImprove the attenuation effectQuick responseTransportation and packagingMetal-working apparatusFiber ChemistryAqueous solution

The invention discloses a preparation method for preparing a continuous fiber copper pipe. According to the specific technical scheme, the preparation method comprises the steps that surface treatment of polypropylene continuous fibers is carried out; a sodium hydroxide solution is adopted for chemical oil removal, a chromic anhydride and sulfuric acid solution is used for surface roughening treatment, an acidic tin saline solution is used for fiber sensitization, a silver nitrate and ammonia water solution is used for fiber surface activation, and a formaldehyde solution is used for fiber reduction; then fiber chemical copper plating and fiber copper plating are carried out, and bivalent copper salt is adopted as main electroplating salt; the polypropylene fibers are removed under the oxidizing atmosphere; and the fiber copper pipe is obtained through reduction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

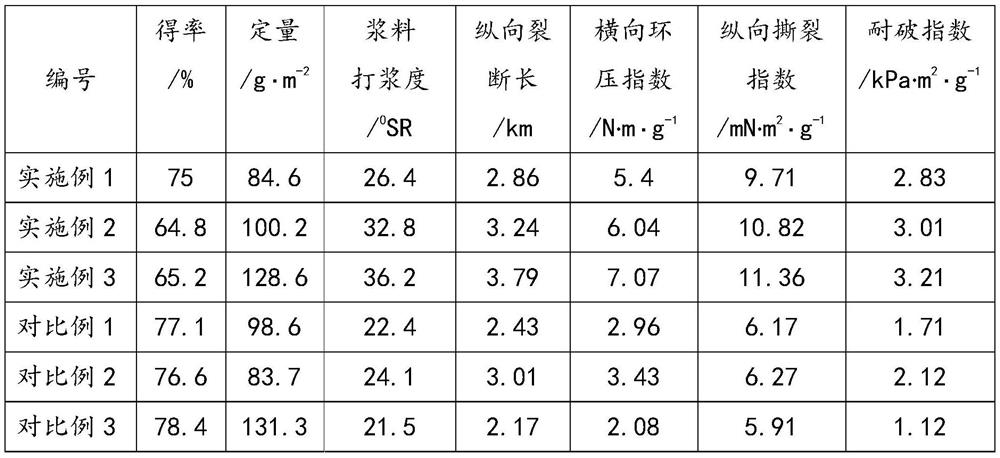

Preparation method of natural-color bamboo fiber biochemical mechanical pulp

ActiveCN110700004AReduce cost pressureMeet needsPretreatment with alkaline reacting compoundsPulp beating methodsFiber ChemistryFermentation

The invention belongs to the field of pulping and papermaking, and specifically relates to a preparation method of a natural-color bamboo fiber biochemical mechanical pulp. The method comprises the following steps: 1) preparing materials by a dry method; 2) sending bamboo chips obtained in the step 1) to a press for pressing; 3) mixing animal manure and the bamboo chips, and screened-out finely-divided debris such as bamboo sawdust, bamboo piths and knots according to a ratio, then performing aerobic fermentation composting, and adding efficient active biological complex bacteria while mixing;4) performing screening and dust removal treatment after fermentation is completed; 5) washing away surface substances of the bamboo chips after screening and dust removal, and removing excess water;6) performing pre-impregnation with a lye; 7) performing pulp grinding or pulp beating; and 8) performing papermaking. The method uses the combination of biological, chemical, and physical methods toproduce the natural-color bamboo fiber chemical mechanical pulp for packaging. At the same time, the method makes full use of the leftover materials in the production process to turn waste into treasure, and realizes sufficient and high-quality utilization of bamboo raw materials.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

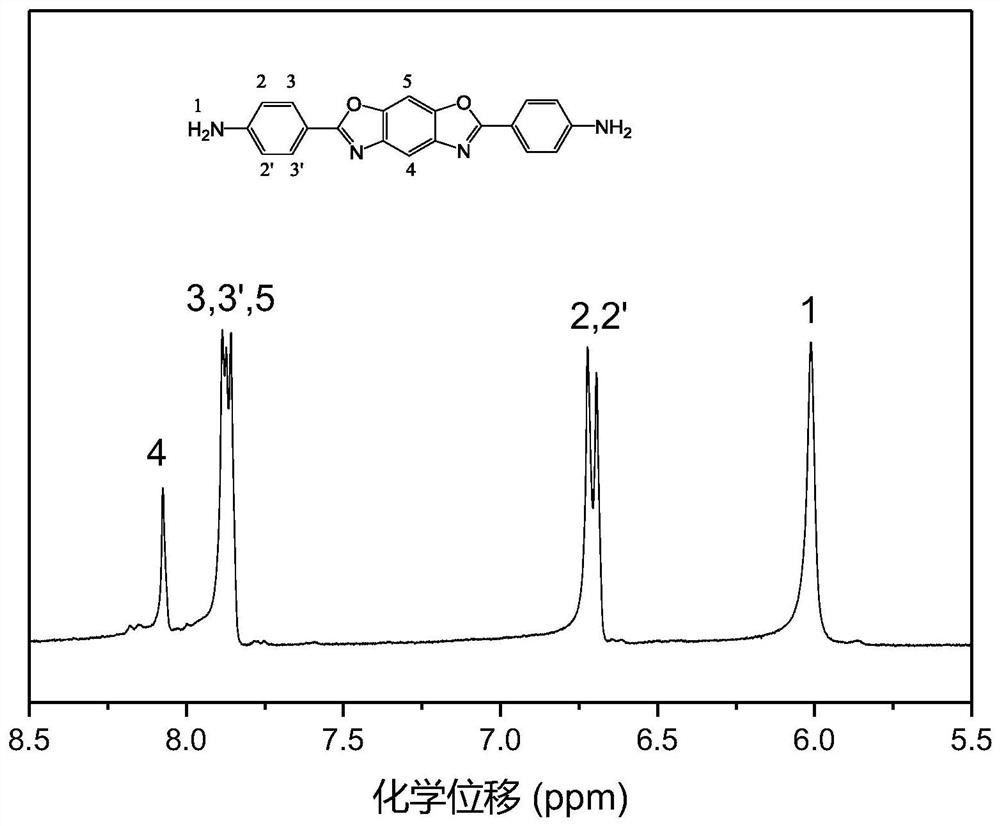

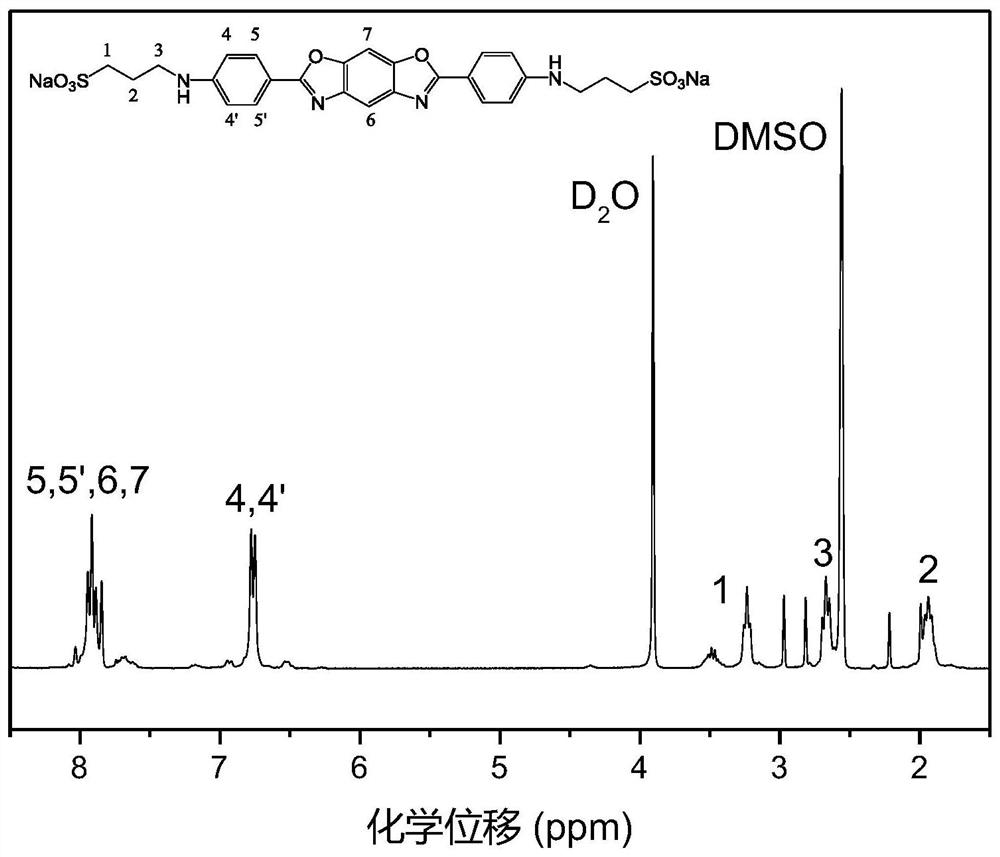

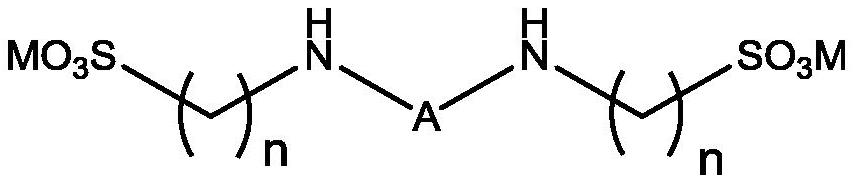

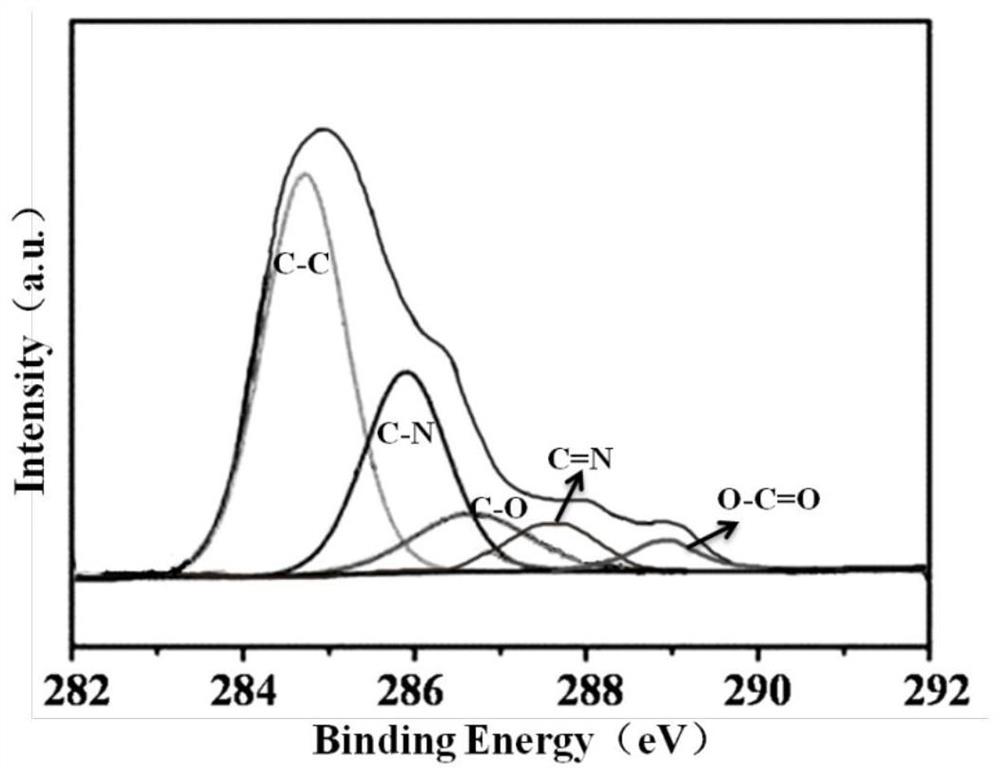

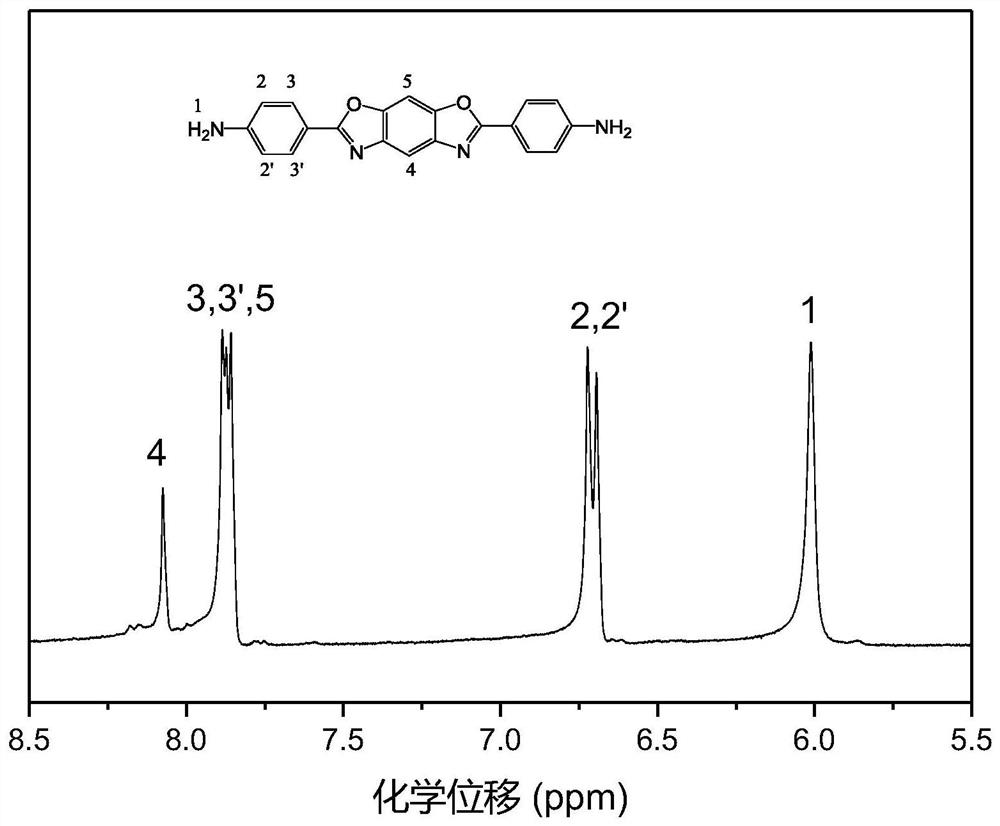

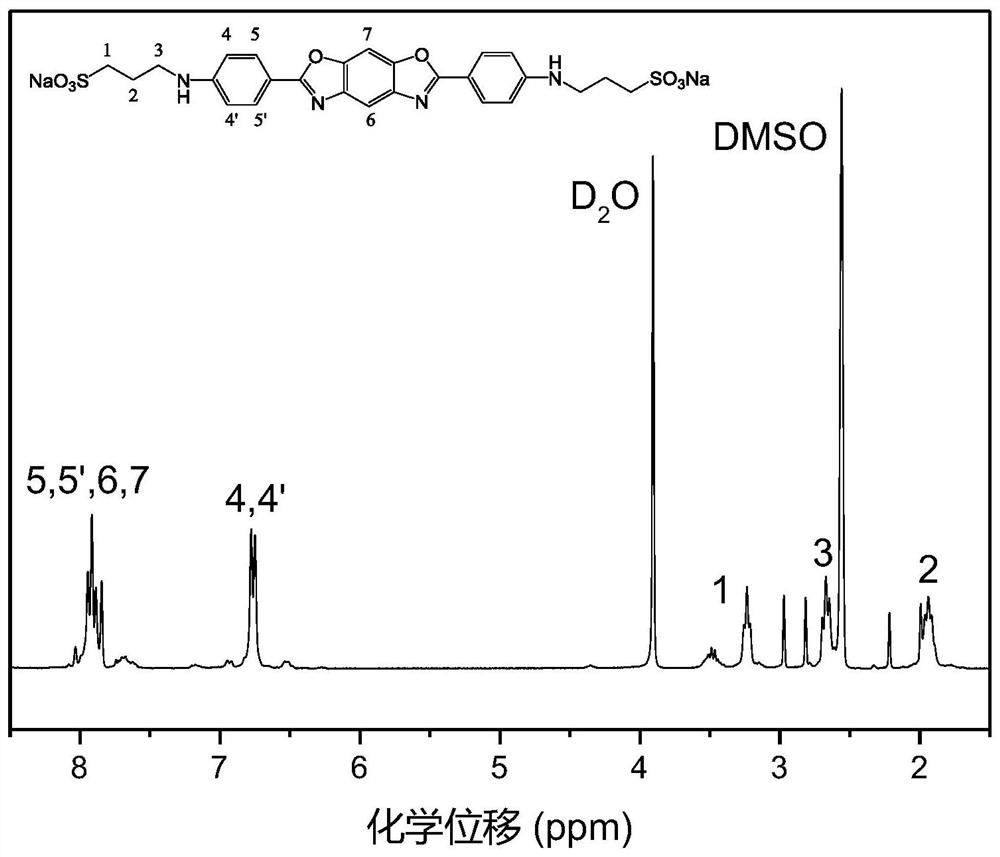

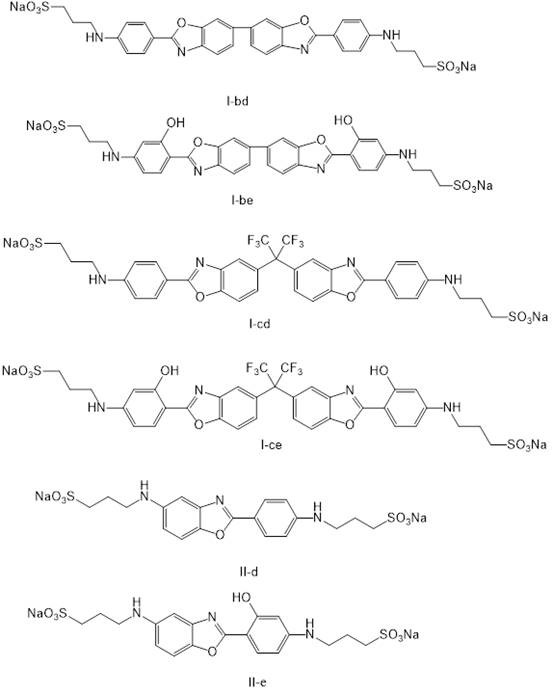

Benzoxazole ionic compound, PBO fiber emulsion sizing agent containing benzoxazole ionic compound and preparation method of PBO fiber emulsion sizing agent

ActiveCN111825696ANovel structureGood compatibilityOrganic chemistryFibre typesBenzoxazoleOrganic solvent

The invention discloses a benzoxazole ionic compound shown as a formula X, a sizing agent containing the compound, and a preparation method and application of the sizing agent. The benzoxazole ionic compound shown in the formula X is similar to the PBO fiber in chemical structure, the compatibility of the sizing agent and the PBO fiber can be improved, and the preparation process is simple and easy to operate. According to the sizing agent, the problems that an existing sizing agent is poor in compatibility with the PBO fiber, a large number of flammable and combustible organic solvents need to be used in the sizing agent, and nano reinforcements in the sizing agent are difficult to effectively cover the surfaces of the fibers are solved. The sizing agent takes water as a solvent, is greenand efficient, is simple and environment-friendly to prepare, and not only can keep the original tensile strength of PBO fibers, but also can remarkably improve the IFSS of the composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of manufacturing method of regenerated leather

InactiveCN103952943BAvoid churnImprove product qualityPretreatment with water/steamInorganic compound additionPolymer scienceFiber Chemistry

The invention relates to preparation methods of non-woven materials and particularly relates to a preparation method of regenerated leather. The preparation method comprises the following steps: sequentially extracting leather fibers, blending materials, distributing the materials, maintaining slurry, automatically draining water, dynamically pressing and dehydrating, flatly pressing and moulding at high pressure, drying, cutting edges, coiling, carrying out surface-treating, coating or moving a film to prepare a continuous broad product, wherein the fiber extraction step comprises the following steps: smashing leather and extracting fibers and putting the fibers in water and soaking; the material blending step comprises the following step: putting the soaked leather fibers and a chemical assistant in a stirring barrel to be uniformly stirred; the slurry maintaining step comprises the following step that the blended slurry is distributed on a conveyer belt to be fed above a slurry maintaining device to accomplish the polymerization reaction to form a basic form of leather blank slurry; the dynamically pressing and dehydrating step comprises the following step: pressing on the leather blank slurry through a flat pressing disc of a dynamic flat pressing device and squeezing water by means of weight of the flat pressing disc; the step of flat pressing and moulding at high pressure comprises the following step: pressing the leather blank to be moulded by an upper pressure plate of a hydraulic press which descends. The preparation method provided by the invention adopts a simple process flow, is low in cost, high in production efficiency, good in product quality, and wide in application range and has energy-saving and environment-friendly effects.

Owner:周文彬

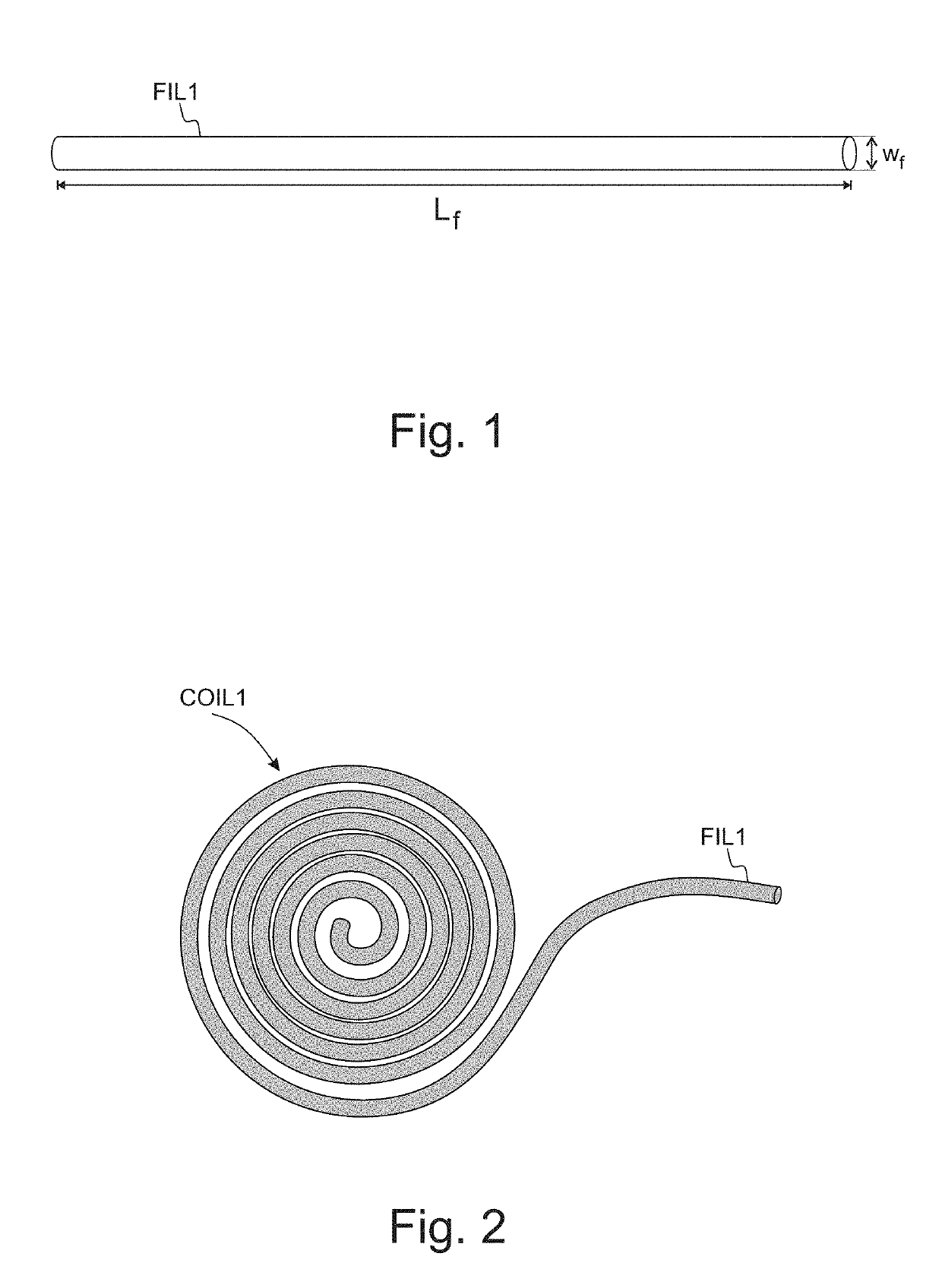

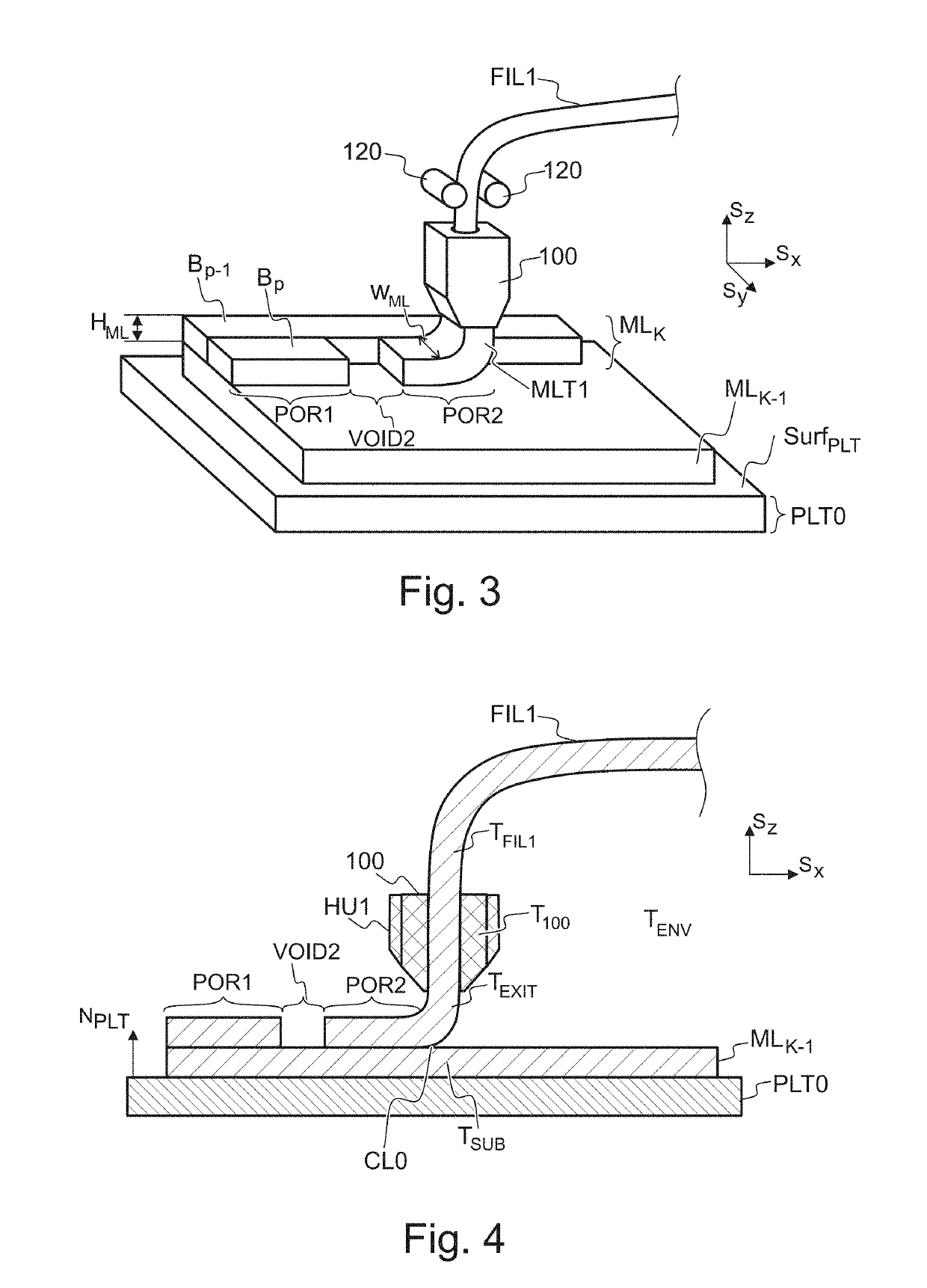

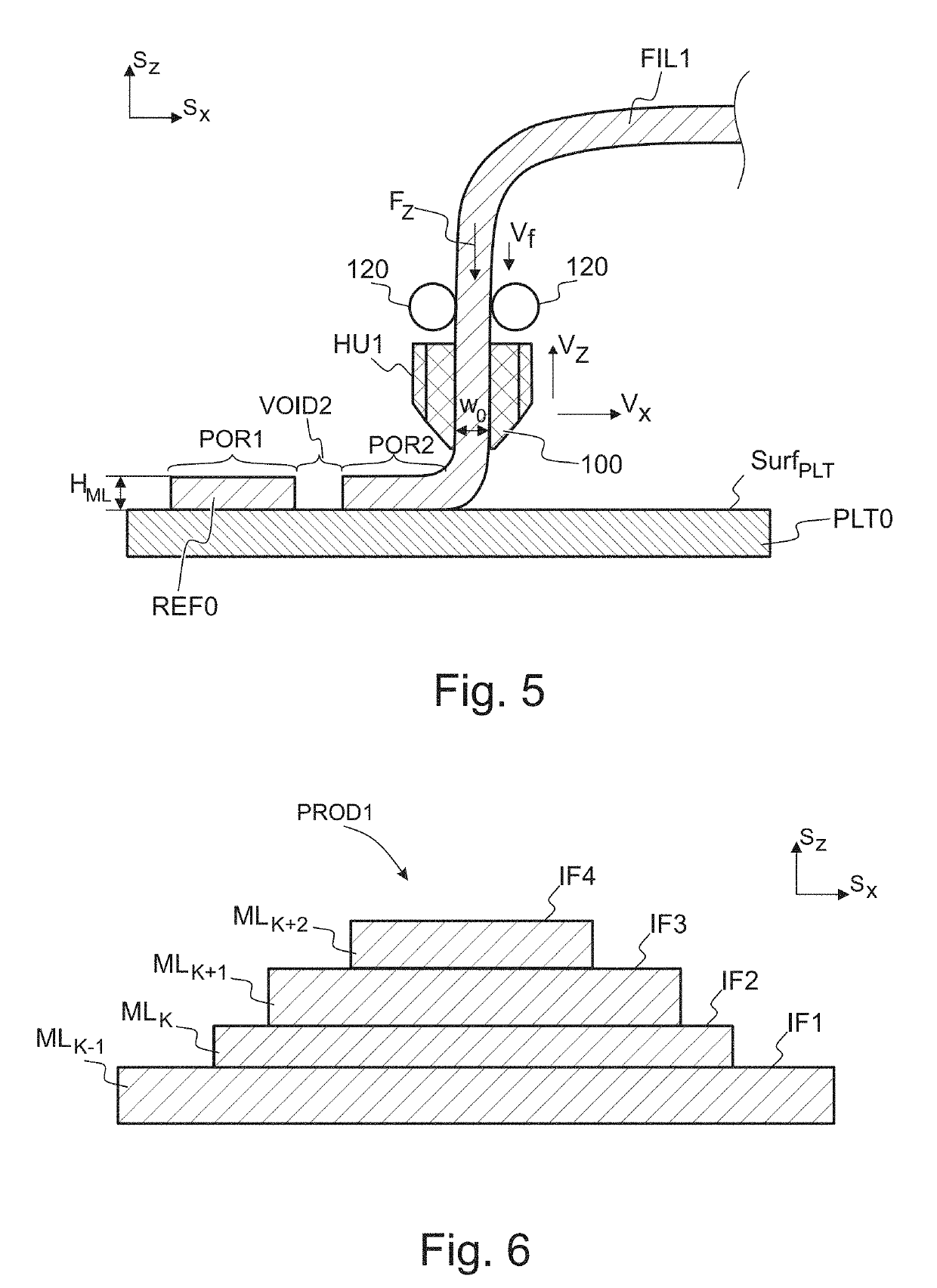

Composite material for additive manufacturing of a three-dimensional composite product

ActiveUS10406747B2Increase brightnessImprove rheologyAdditive manufacturing apparatusMonocomponent cellulose artificial filamentCellulose fiberViscosity

The invention relates to a composite material filament having rheological characteristics suitable for use in additive manufacturing by extrusion, a method for manufacturing a three-dimensional composite product with an additive manufacturing system from a filament of such composite material, and to a three-dimensional composite product obtained by an additive manufacturing system using such composite material. The filament is formed of material comprising semi-crystalline polylactic acid and chemical pulp of wood-based cellulose fibers, wherein the amount of chemical pulp of wood-based cellulose fibers is selected such that sufficient complex viscosity is obtained at melt state, such that upon additive manufacturing by extrusion, composite melt formed of the filament has a ratio of shear storage modulus to shear loss modulus G′ / G″ equal to or higher than 1.0 at a temperature equal to or higher than 133° C.

Owner:UPM-KYMMENE OYJ

Polypropylene fiber chemical treatment agont and its application in tobacco leaf feeding process

A chemical for treating the tip filter made of polypropylene fibres and the tobacco leaves used for cigarettes is prepared from multiple kinds of souring agent, 5-methyl-2-isopropyl cyclohaxanol and synthetic perfume. It can prevent the generation of irritative hot smell in the tip filter and cigarette.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

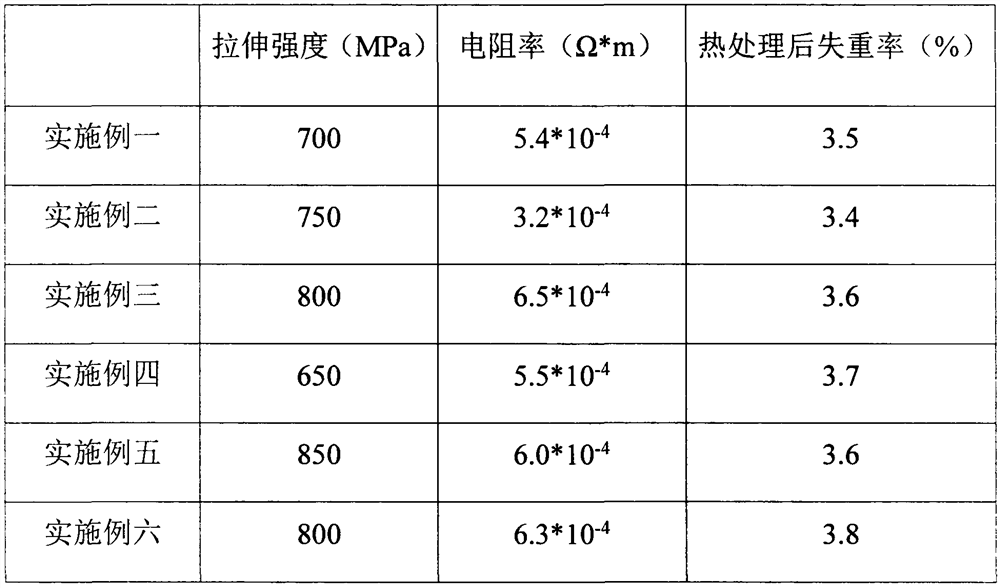

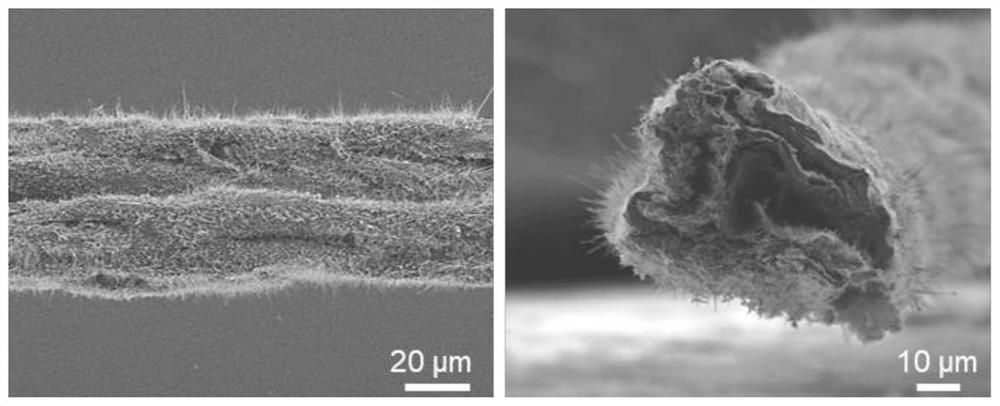

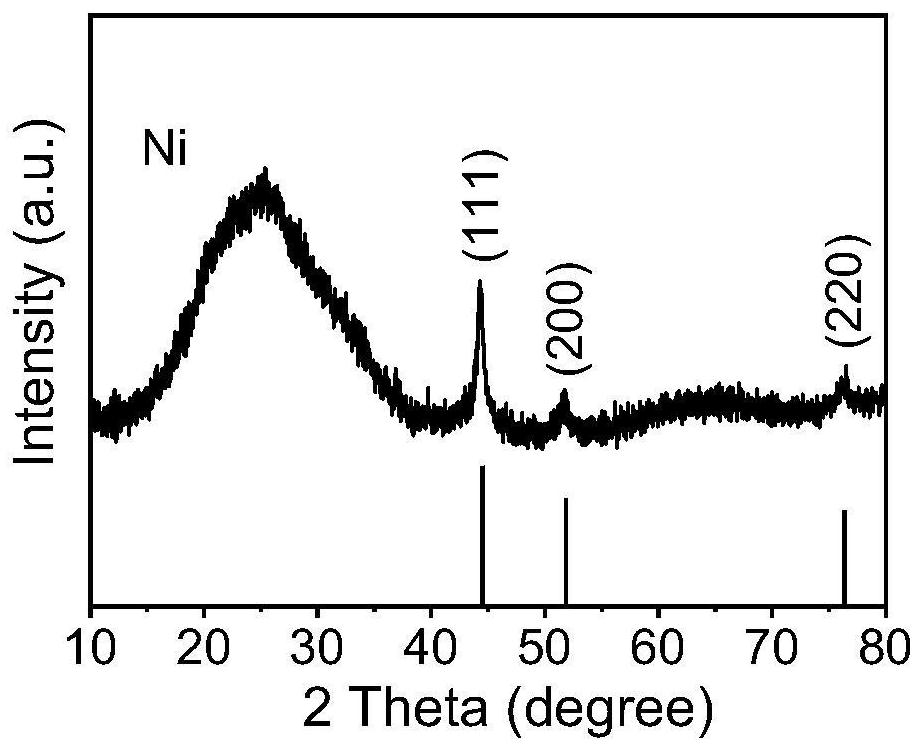

Graphene-based hybrid multilayer structure fiber material, preparation thereof and application

ActiveCN112522813ASimple methodNo emissionsCarbon fibresFibre chemical featuresSpinningFiber Chemistry

The invention discloses a preparation method of a graphene-based hybrid multilayer structure fiber material and application of a sensor material, and belongs to the technical field of preparation of functional nano materials. Transition metal ion cross-linked graphene oxide fibers are prepared through a wet spinning technology, the strength and the conductivity of the fibers are improved through chemical reduction, then the fibers and a proper amount of melamine are mixed in an inert gas atmosphere, thermal reduction in-situ catalytic growth of carbon nanotubes is conducted, and graphene-basedhybrid multilayer structure fibers are obtained. The material prepared by the preparation method of the graphene-based hybrid multilayer structure fiber material has the advantages of high sensitivity, large detection range, high response speed and good stability in sensor material application. The whole preparation process of the material is simple, no toxic product is generated in the reactionprocess, the energy consumption is low, and the method is environment-friendly and suitable for industrial large-scale production.

Owner:NANJING UNIV OF TECH

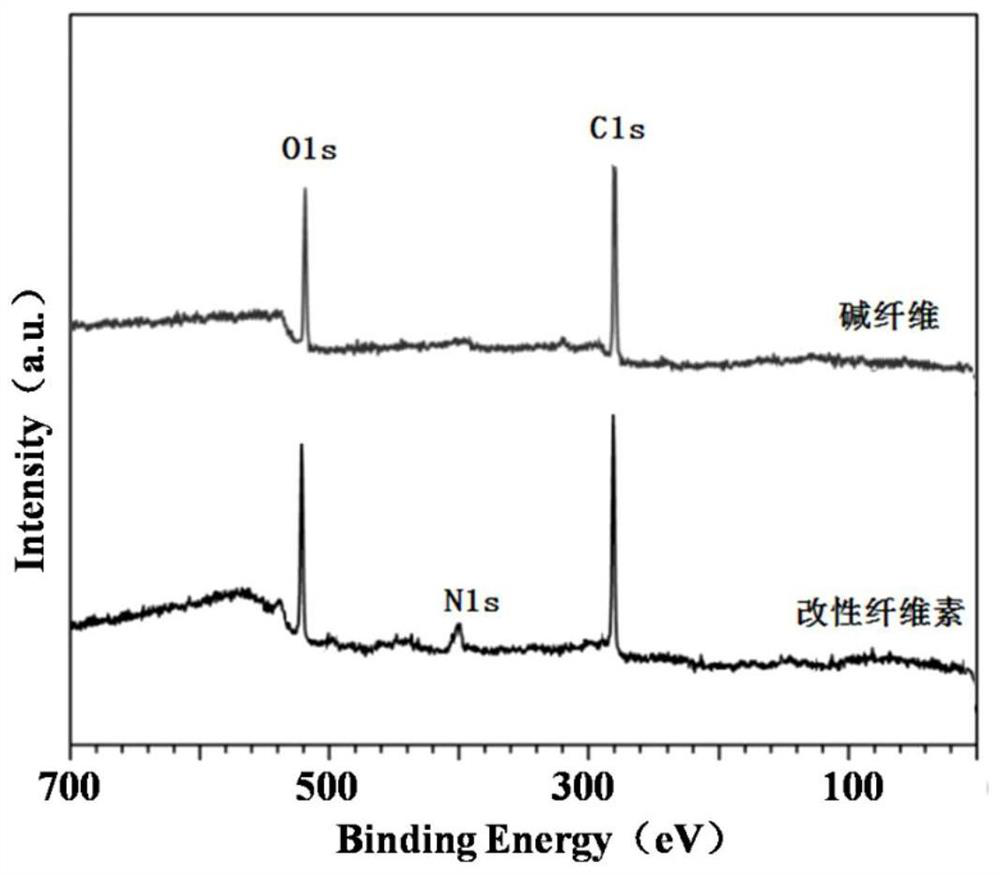

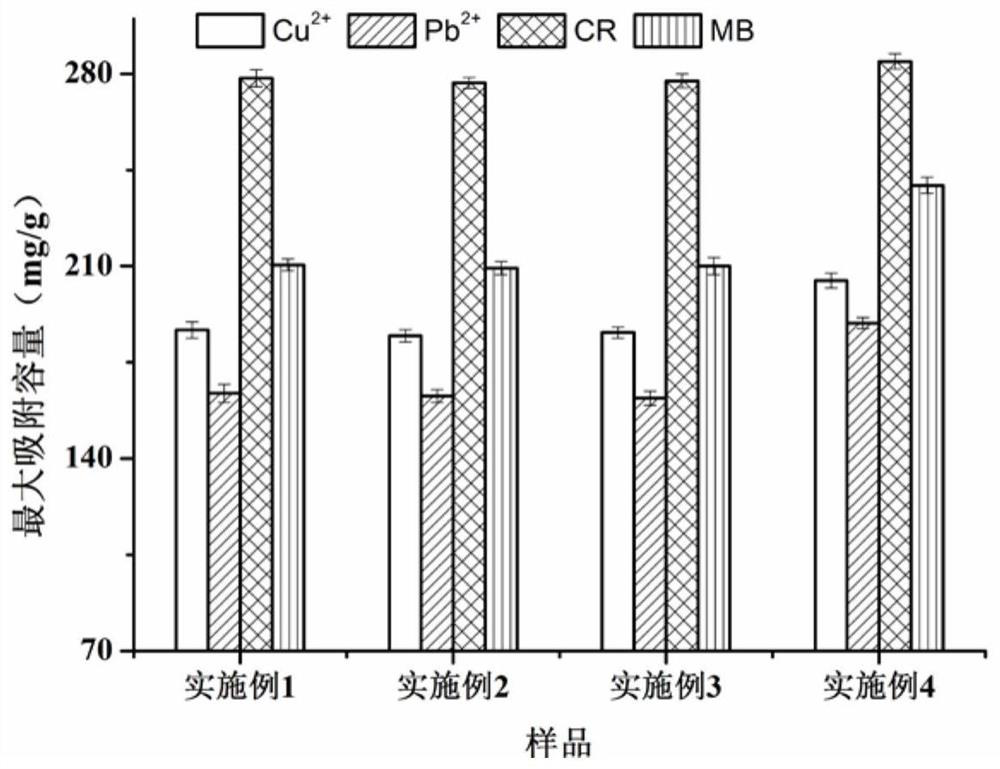

Cellulose-based composite adsorbent for wastewater treatment

InactiveCN112473626AHigh porosityImprove adsorption capacityOther chemical processesWater contaminantsCelluloseFiber Chemistry

The invention discloses a cellulose-based composite adsorbent for wastewater treatment, belonging to the technical field of adsorbents for wastewater treatment. The preparation method of the cellulose-based composite adsorbent comprises the following steps: pretreating bagasse, namely after bagasse raw materials are separated, purified and crushed, carrying out ultrasonic wave-alkali liquor-ultrasonic wave combined pretreatment to generate alkali fibers; carrying out chemical modification, namley carrying out oxidation treatment on the alkali fibers by adopting sodium periodate to obtain oxidized fibers; putting the oxidized fibers into a reaction medium, adding acid anhydride for a reaction, successivly conducting washing, dipping, filtering and drying, and carrying out an esterificationreaction with guanosine to obtain a product A; and putting the product A into an aqueous diaminopimelic acid solution for a constant-temperature reaction, and then carrying out washing and drying to obtain the cellulose-based composite adsorbent. The cellulose-based composite adsorbent for wastewater treatment prepared by the invention has high adsorption performance and shows a good removal effect on heavy metal ions and printing and dyeing wastes in wastewater; and the adsorbent is recyclable, simple to operate and high in adsorption efficiency.

Owner:杭州鹿扬科技有限公司

A kind of benzoxazolium ion compound and the PBO fiber emulsion sizing agent containing the compound and preparation method thereof

ActiveCN111825696BNovel structureGood compatibilityOrganic chemistryFibre typesBenzoxazoleOrganic solvent

A benzoxazolium ion compound represented by the following formula X, a sizing agent comprising the compound, a preparation method and use thereof. The chemical structure of the benzoxazolium ion compound represented by formula X is similar to that of PBO fiber, which is beneficial to improve the compatibility of sizing agent and PBO fiber, and its preparation process is simple and easy to operate. The sizing agent overcomes the problems of poor compatibility between the existing sizing agent and PBO fibers, the need to use a large amount of flammable and explosive organic solvents in the sizing agent, and the difficulty in effectively covering the fiber surface with nano reinforcements in the sizing agent. The sizing agent uses water as a solvent, is green and efficient, is simple to prepare, and is environmentally friendly, and the sizing agent can not only maintain the original tensile strength of the PBO fiber, but also significantly improve the IFSS of the composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of anti-corrosion anti-static coating and preparation method thereof

InactiveCN105778638BAvoid the defect that it is easy to aggregate and not easy to disperseAvoids the disadvantage of requiring larger volume fractionsAnti-corrosive paintsElectrically-conductive paintsMetal fiberPolymer science

Owner:SHENGYA TECH DALIAN

Glass fiber chemical polishing agent and preparation method and application thereof

InactiveCN111592830ASimple preparation processLow pricePolishing compositionsGlass fiberFiber Chemistry

The invention relates to a glass fiber chemical polishing agent and a preparation method and application thereof, in particular to a chemical polishing agent capable of effectively reducing the surface roughness of glass fibers and a preparation method thereof, and belongs to the technical field of glass fiber manufacturing, the technical field of organic / inorganic chemical engineering and the field of thermal protection base materials. The roughness of the glass fiber is reduced to 53-92 nm from 210 nm or above, and the tensile strength of the monofilament is remarkably improved to 1205-1654MPa from 917 MPa; the surface roughness of the glass fiber treated by the polishing agent is obviously reduced, and then the micro-defect size and quantity are obviously reduced and the strength of the glass fibers is obviously improved; in addition, the glass fiber polishing agent has the greatest characteristics of simple preparation process, wide raw material source, low price, simple and feasible treatment process, large mechanical property improvement amplitude and the like.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Manufacturing method of novel chemical fiber blended yarn

InactiveCN110284229AImprove adsorption capacityHas the function of filtering and purifyingYarnFiberActivated carbon

The invention belongs to the technical field of blended yarns and particularly relates to a manufacturing method of a novel chemical fiber blended yarn. The problems of high thickness and poor heat preservation performance and gas permeability of an existing garment fabric are solved. The following scheme is proposed. The method comprises the steps that cotton fibers, activated carbon fibers, chemical fibers and raw bamboo fibers are subjected to impurity removal, released and subjected to opening, the cotton fibers, activated carbon fibers and raw bamboo fibers are conveyed to a carding machine for carding, the chemical fibers are heated, mix-fused and prepared into a spinning solution, and through spinning, composite fibers are prepared; the cotton fibers, activated carbon fibers and raw bamboo fibers are convoyed into a combing machine; the cotton fibers, activated carbon fibers, raw bamboo fibers and composite fibers after being combed are evenly mixed and drafted; the drafted fibers are twisted and coiled to prepare a finished blended yarn product, and the prepared finished product is proper in thickness and good in heat preservation performance and gas permeability.

Owner:沛县谦和纺织有限公司

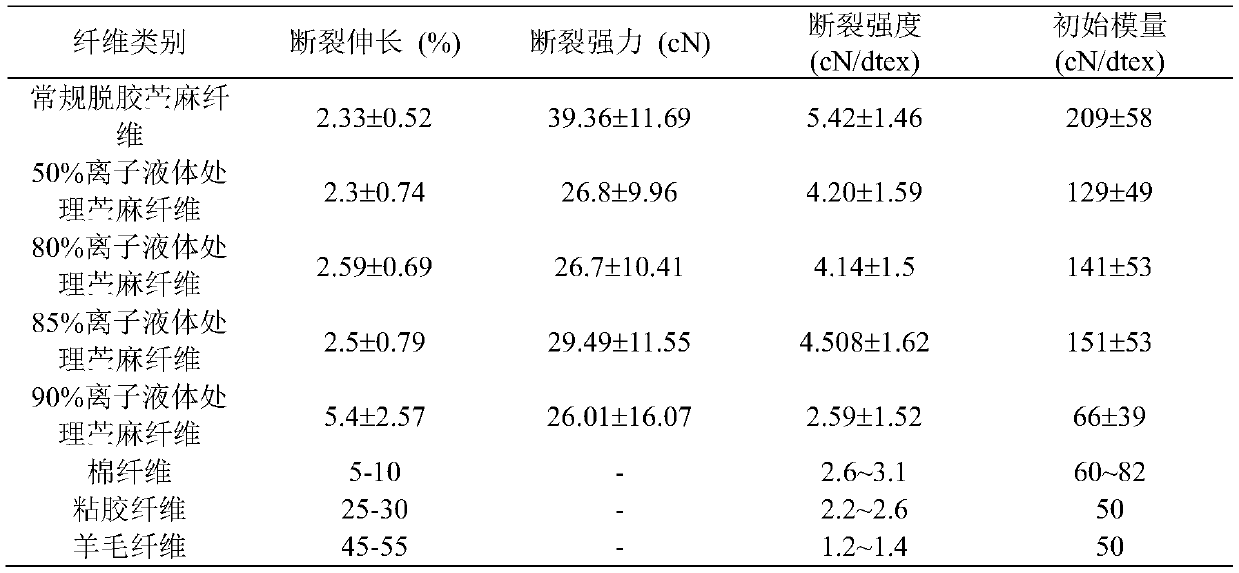

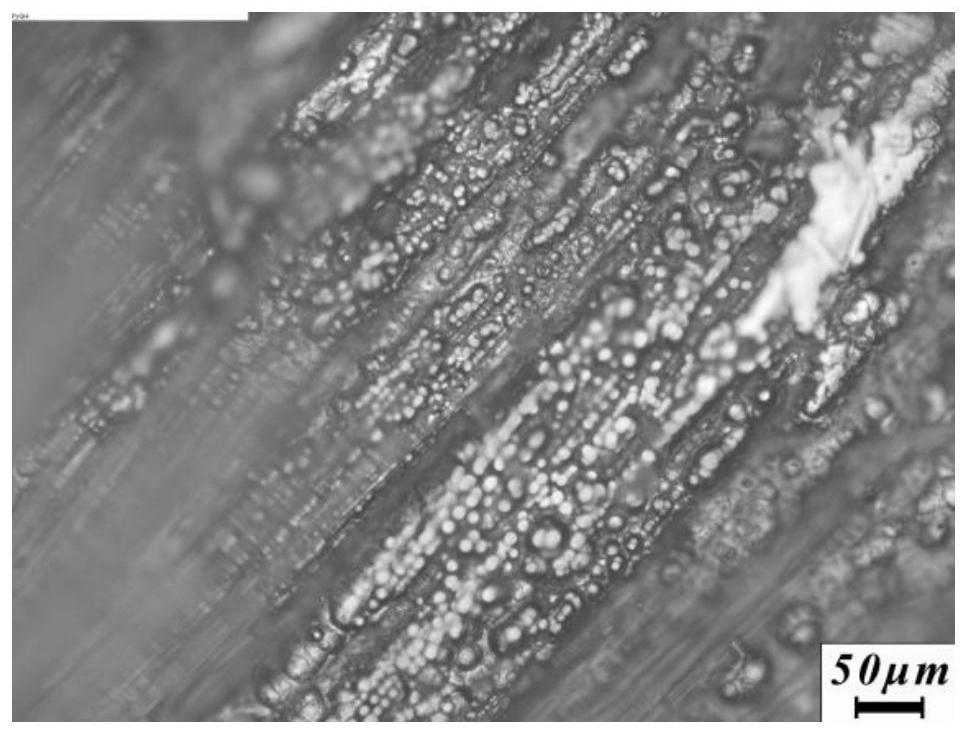

Ramie fiber softening method

ActiveCN111379162AReduce crystallinityLow modulusPhysical treatmentGrip property fibresPolymer scienceFiber Chemistry

The invention relates to the field of textile natural fibers, and provides a ramie fiber softening method comprising the following step (1) of immersing ramie fibers into a sodium hydroxide solution for swelling treatment; the step (2) of taking out the swelled ramie fibers, and placing the ramie fibers into water; gradually adding acidic solutions till pH is neutral, and washing the ramie fiberswith purified water; the step (3) of freezing and drying the washed ramie fibers, so that gaps of the ramie fibers are reserved; the step (4) of immersing the frozen and dried ramie fibers into ionicliquid with a certain concentration for ultrasonic treatment; the step (5) washing and drying the treated ramie fibers to obtain softened ramie fibers. According to the ramie fiber softening method, the crystallinity and modulus of the ramie fibers can be reduced obviously; since lots of gaps are increased in the ramie fibers, the moisture absorption and release properties of the fibers are improved; and meanwhile, by this way, the chemical composition of the fibers is not damaged, and the antibacterial component of the fibers can be reserved, so that the antibacterial activity of the fibers is reserved.

Owner:QINGDAO UNIV

A method for electroless nickel-phosphorus plating of quartz fibers

ActiveCN110205611BReduce usageImprove bindingLiquid/solution decomposition chemical coatingElectroless nickelPhysical chemistry

The invention relates to a method for chemical nickel-phosphorus plating of quartz fibers, and belongs to the technical field of chemical nickel plating. According to the method, the catalytic actionof nickel is utilized, an activating agent is added into a plating solution, through the matching effect of a rotor and the quartz fiber mechanical grinding, a nickel-phosphorus coating can be directly deposited on the surface of the quartz fibers, the pre-treatment process of coarsening, sensitizing and activating is omitted, meanwhile, the use of palladium chloride with toxicity and high price is avoided, the process flow is simplified, the cost is reduced, the operation safety is improved, and the method has a good industrial application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

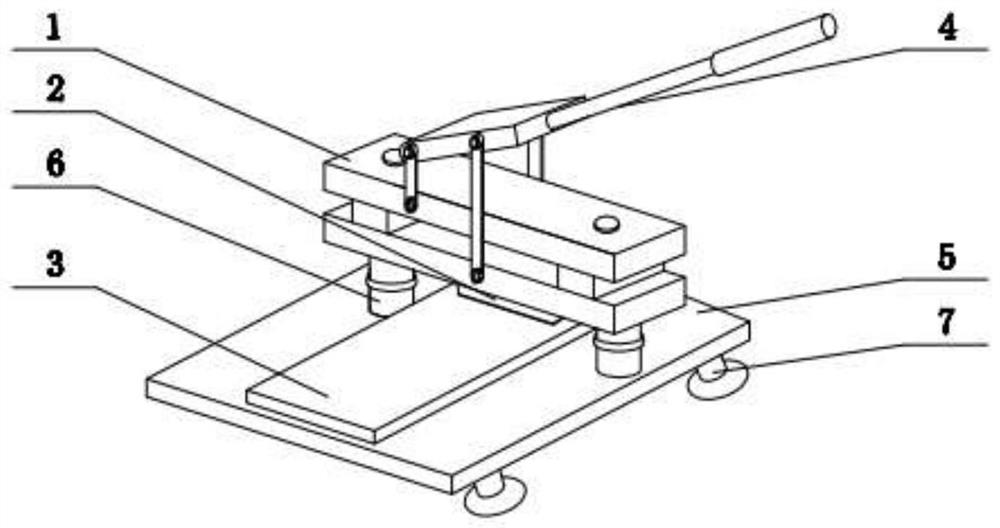

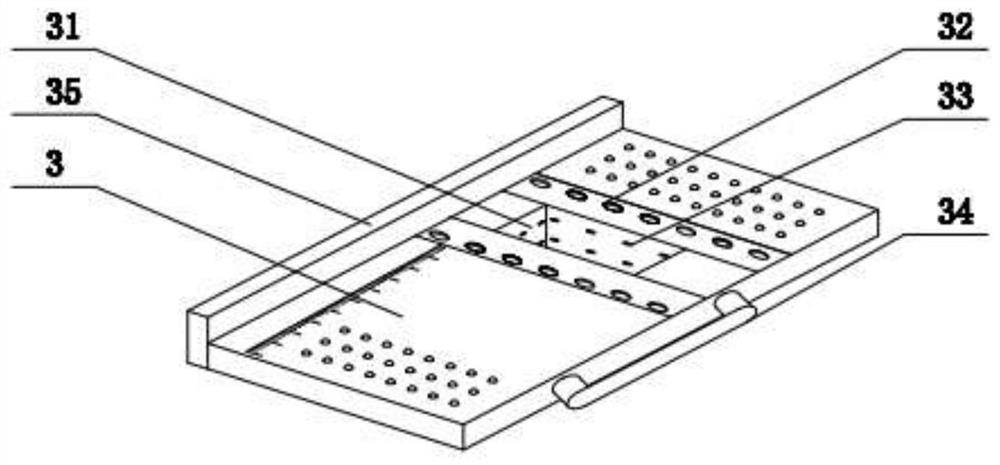

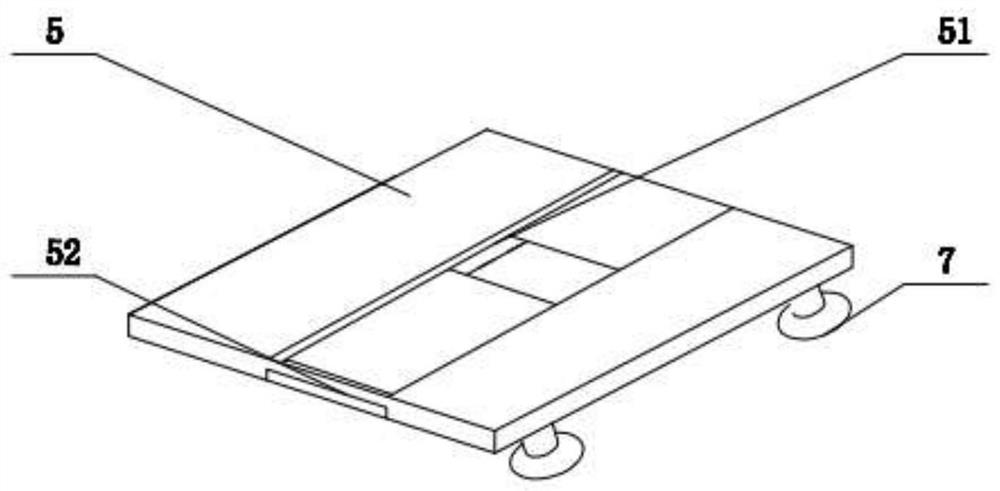

Linear density sampling device for carbon fiber chemical composite material

PendingCN112857857AReasonable structural designGood dustproofWithdrawing sample devicesCarbon fibersFiber Chemistry

The invention discloses a linear density sampling device for a carbon fiber chemical composite material. The sampling device comprises an operation table, a control handle is arranged over the operation table, a sampling opening is formed below the operation table, buffering pads are arranged at the two sides of the sampling opening, the upper ends of the buffering pads are connected with the operation table, a base is arranged at the bottom of each buffering pad, a dust collection device is installed in the base, a sizing plate is arranged over the dust collection device and slides on the surface of the base, positioning piles are arranged in the periphery of the bottom of the base, chip removal holes are formed in the sampling area, dust collection holes are formed in the two sides of the sampling area, a handle is arranged at one side of the sizing plate, and a guide seat is far away from the handle and is arranged in the other side of the sizing plate. The sampling device has the advantages of convenience, rapidness and high dustproof performance, and further solves the problems that most operations are tedious, the equipment structure is complex, and a large amount of dust is generated during sampling.

Owner:NANJING XIAOZHUANG UNIV

Preparation technology of textile with healthcare function

The invention discloses a preparation technology of a textile with the healthcare function, and belongs to the field of bamboo products. The technology is characterized in that the bamboo fiber content of a single fiber textile is 100%, a mixture fabric is formed by adopting the bamboo fiber as the main part and mixing jute fiber, silk fiber and chemical fiber proportionally, the bamboo fiber canbe natural bamboo fiber or bamboo viscose, the finished spinning product has the cool, moisture-absorbing, breathable and antibacterial unique good performance, the comfortable and healthcare advantages are brought to wear or use of people, and the wide market development prospect is achieved.

Owner:南通靓奇纺织有限公司

Manufacturing process of high-count linen tow yarn

The invention discloses a manufacturing process of high-count linen tow yarn. The manufacturing process comprises the following steps of carding raw materials by a hackling machine: taking tows with uniform thickness and uniform color based on the number of needles on the middle section of the hackling machine; and performing humidification curing, combined carding and gilling, and performing combing, roving and boiling and bleaching, wherein the boiling and bleaching process comprises four steps of acid pickling, chlorite bleaching, light boiling and oxygen bleaching. According to the invention, the raw materials are carefully selected, and the relatively uniform tows with good fineness consistency are selected; tow fibers are good in splitting degree and small in difference, so that the effect of the independently selected short fibers is far better than the effect of post-processed fibers; and in addition, improvement lies in boiling and bleaching, the fibers with the relatively good fineness are used, and chemical processing, namely, the boiling and bleaching technology is moderated, so that in the processing processes of chlorite bleaching and oxygen bleaching, the fibers are lighter than those in a conventional technology, the fibers are not damaged, and in order to ensure that the splitting degree is suitable and one step of light boiling is carried out, the spinning production and quality are improved.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

PLA multi-composite fabric and preparation method thereof

PendingCN114836872AMulti-collocation effectMore convenientWoven fabricsPolymer scienceFiber Chemistry

The invention discloses a PLA multi-composite fabric and a preparation method thereof. The preparation method comprises the following steps: taking 100-150 parts of PLA fibers and 100-150 parts of composite fibers, starting to carry out textile processing, and carrying out opening picking, combing, drawing, roving, spinning, spooling and weft twisting to obtain the prepared composite fabric. In the step S1, the composite fiber is any one or more of PLA fiber or PLA fiber, natural fiber and chemical fiber; according to the PLA fiber composite fabric, the fabric is woven by any one or more of the PLA fibers, the natural fibers and the chemical fibers in a mixed mode, so that the PLA fibers obtain more matching effects in the weaving process, the convenience in the using process is improved, and more convenience is brought to people.

Owner:广州市盛鸿纺织科技有限公司

A kind of preparation method of natural color bamboo fiber biochemical mechanical pulp

ActiveCN110700004BReduce cost pressureMeet needsPretreatment with alkaline reacting compoundsPulp beating methodsFiber ChemistryAnimal feces

The invention belongs to the field of pulping and papermaking, in particular to a method for preparing natural-color bamboo fiber biochemical mechanical pulp. The method comprises the following steps: 1) using a dry method to prepare materials; 2) sending the bamboo chips obtained in step 1) into an extruder for pressing; 3) combining animal manure with bamboo chips, bamboo chips, bamboo pith and knots, etc. Fine debris, after mixing in proportion, carry out aerobic fermentation and composting, and add high-efficiency active biological complex bacteria at the same time; 4) After the fermentation is finished, carry out screening and dust removal treatment; 5) Wash the bamboo chips after screening and dust removal by washing machine Surface material and remove excess water; 6) pre-impregnation with lye; 7) pulping or beating; 8) copying. This method combines biological, chemical and physical methods to produce natural color bamboo fiber chemical mechanical pulp for packaging, and at the same time makes full use of the leftovers in the production process, turning waste into treasure, and realizing the fullness and high quality of bamboo raw materials use.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com