Cellulose-based composite adsorbent for wastewater treatment

A cellulose-based, composite adsorption technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of non-biodegradable, high production cost, secondary pollution, etc. Achieve the effects of enhancing adsorption performance, increasing porosity, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

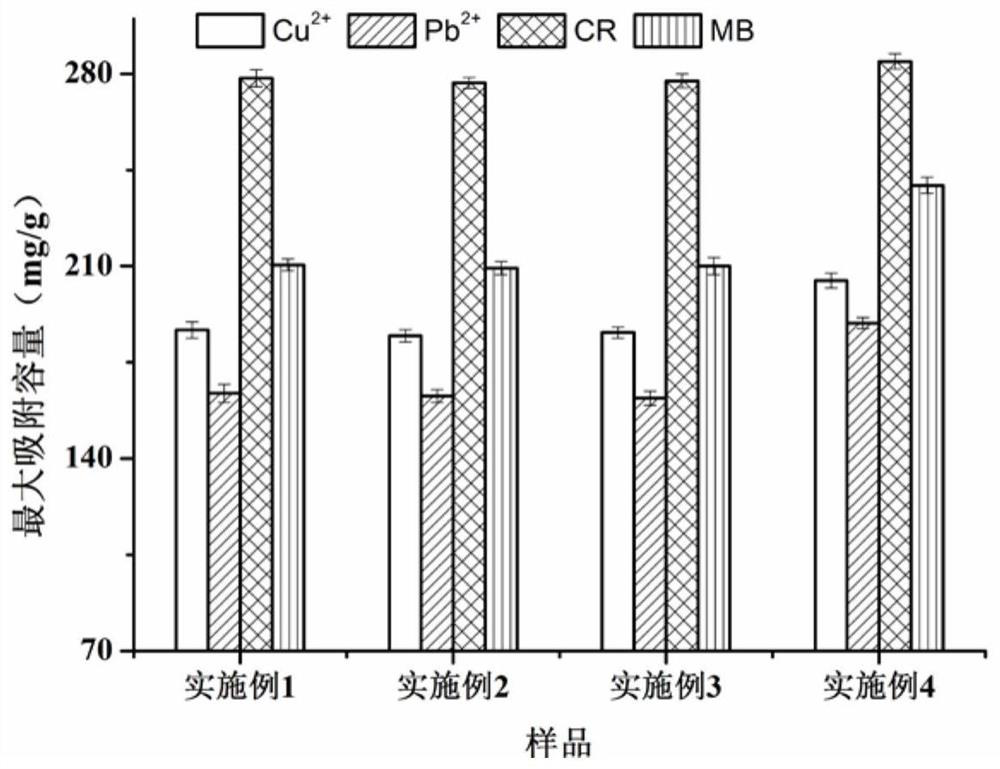

Embodiment 1

[0035] Preparation of cellulose-based composite adsorbents for wastewater treatment:

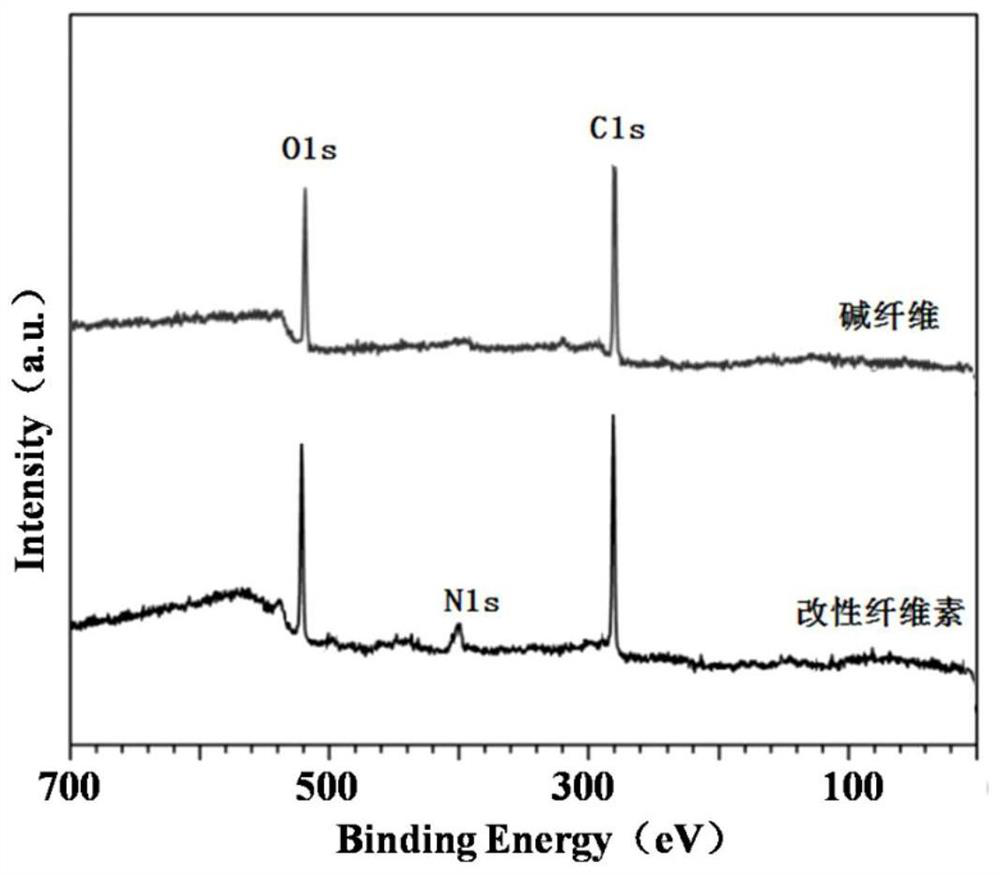

[0036] S1: Bagasse pretreatment, remove impurities from the bagasse raw material, add 3% sodium hydroxide solution to boil for 20 minutes, wash with water, dry and cut into pieces; then carry out ultrasonic-lye-ultrasonic combined pretreatment: disperse the bagasse In water, control the solid-liquid ratio to 1:30g / mL, and then ultrasonically treat it for 15min; after filtering, place it in a 10% sodium hydroxide solution and boil it for 60min, and control the solid-liquid ratio to 1:30g / mL, Continue ultrasonic treatment for 30 minutes, filter, wash with water until neutral and dry to obtain alkali fiber;

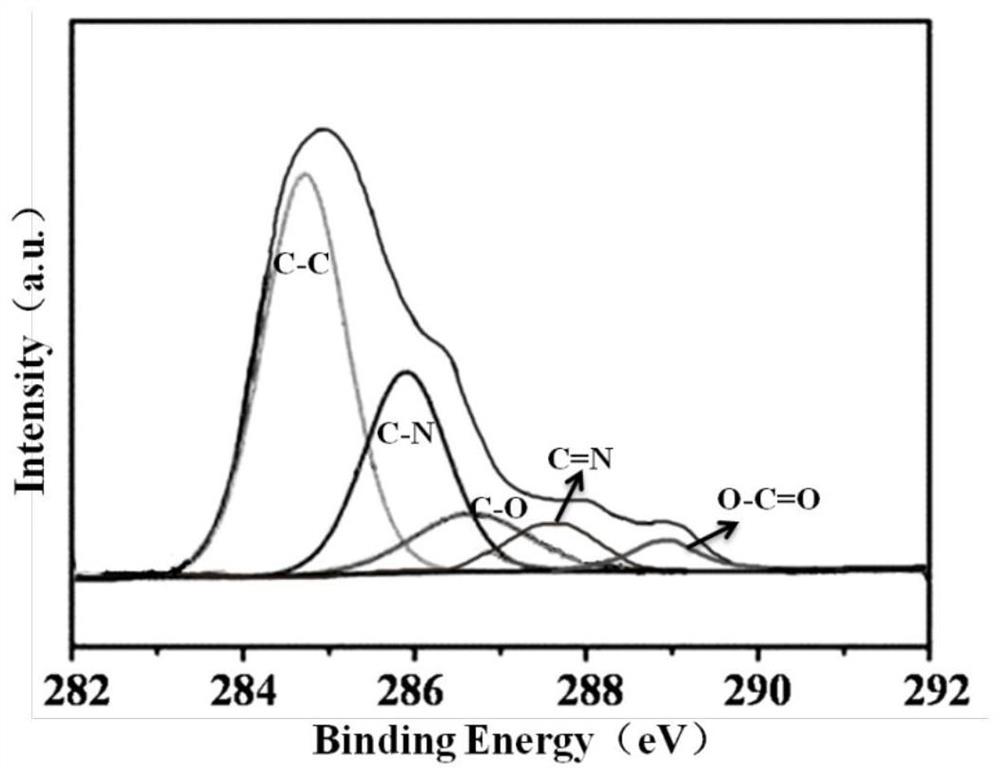

[0037] S2: chemical modification, using sodium perdianate to carry out oxidation treatment to the alkali fiber: the alkali fiber is added to a concentration of 12g / L sodium periodate-ethanol (5%) solution (alkali fiber and periodic acid The solid-to-liquid ratio of sodium is 1:40g / mL), re...

Embodiment 2

[0043] The preparation process is consistent with Example 1, except that the acid anhydride in the preparation process is: succinic anhydride; the mass ratio of oxidized cellulose, acid anhydride, guanosine and diaminopimelic acid is 1:5:5.5:10.

Embodiment 3

[0045] The preparation process is the same as in Example 1, except that the acid anhydride in the preparation process is: succinic anhydride; the mass ratio of oxidized cellulose, acid anhydride, guanosine and diaminopimelic acid is 1:5.5:6.5:11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com