Body paper of washi adhesive tape and production method for body paper

A technology of washi tape and adhesive tape, applied in textiles and papermaking, papermaking, paper coating and other directions, can solve the problem of low quality of base paper of washi tape, and achieve the effects of reducing aging, improving UV resistance and strong tear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

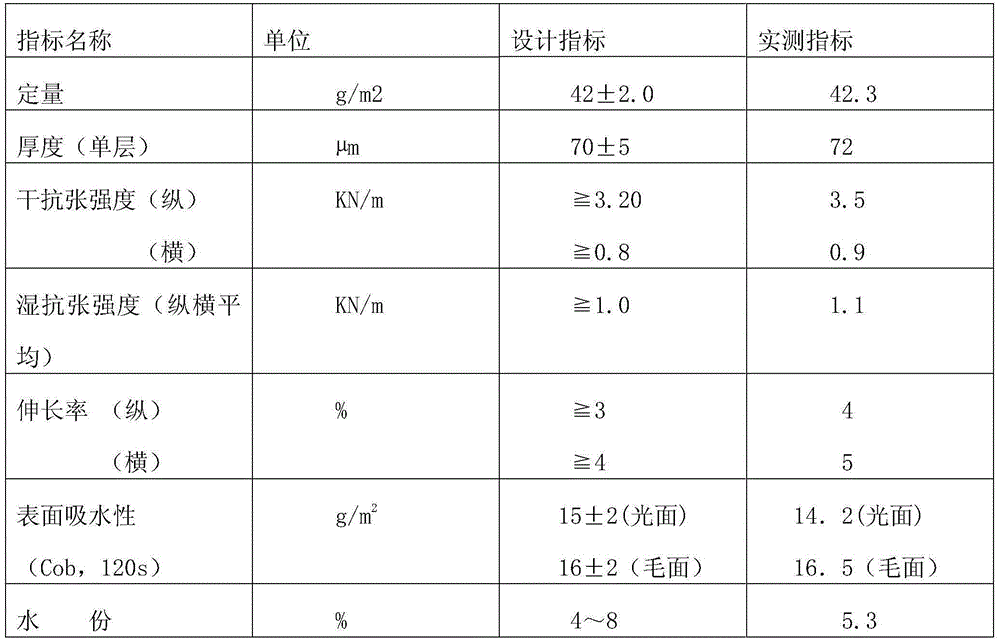

Image

Examples

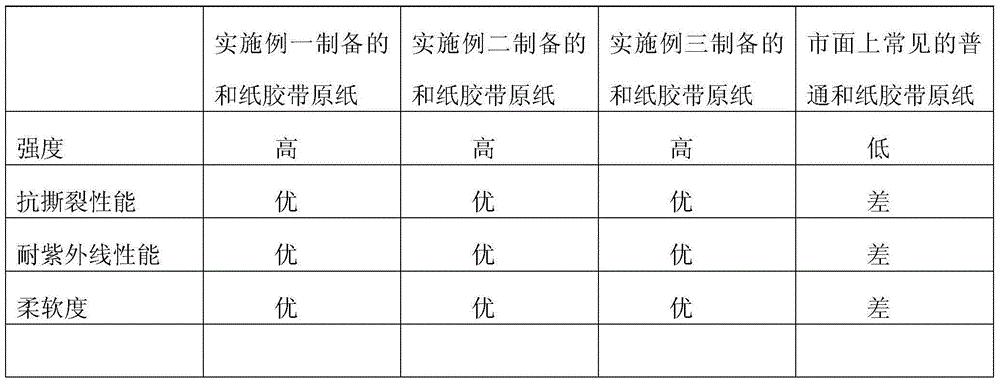

Embodiment 1

[0027] This washi tape base paper is made of the following raw material proportions by weight: 70 parts of long-fiber wood pulp, 20 parts of short-fiber chemical-mechanical wood pulp, 0.5 part of wet strength agent, 20 parts of coated latex, and cork extract Liquid 5 parts.

[0028] Further, the long-fiber wood pulp is softwood wood pulp.

[0029] Further, short fiber chemical mechanical wood pulp is hardwood pulp.

[0030] Further, the coating latex is styrene-acrylic latex.

[0031] The production method of above-mentioned washi tape base paper, comprises the steps:

[0032] The first step is beating treatment. The long-fiber wood pulp and short-fiber chemical-mechanical wood pulp are fully mixed and then put into the hydraulic pulper and added with water for mixing and crushing treatment. In the prize pool, two double-disk refiners are connected in series for slight beating. The beating concentration is 3.0%, the degree of beating is 15°, and the wet weight is 10g.

[0...

Embodiment 2

[0039] This washi tape base paper is made of the following raw material proportions by weight: 75 parts of long fiber wood pulp, 25 parts of short fiber chemical mechanical wood pulp, 2 parts of wet strength agent, 25 parts of coating latex, cork extract Liquid 6 parts.

[0040] Further, the long-fiber wood pulp adopts softwood wood pulp.

[0041] Further, short-fiber chemi-mechanical wood pulp adopts hardwood pulp.

[0042] Further, the coating latex is styrene-acrylic latex.

[0043] The production method of above-mentioned washi tape base paper, comprises the steps:

[0044] The first step is beating treatment. The long-fiber wood pulp and short-fiber chemical-mechanical wood pulp are fully mixed and then put into the hydraulic pulper and added with water for mixing and crushing treatment. In the prize pool, two double-disc refiners are used in series for slight beating. The beating concentration is 3.2%, the degree of beating is 18°, and the wet weight is 13g.

[0045]...

Embodiment 3

[0051] This washi tape base paper is made of the following raw material proportions by weight: 80 parts of long-fiber wood pulp, 30 parts of short-fiber chemical-mechanical wood pulp, 3 parts of wet strength agent, 30 parts of coated latex, and cork extract 8 parts of liquid.

[0052] Further, the long-fiber wood pulp adopts softwood wood pulp.

[0053] Further, short-fiber chemi-mechanical wood pulp adopts hardwood pulp.

[0054] Further, the coating latex is styrene-acrylic latex.

[0055] The production method of above-mentioned washi tape base paper, comprises the steps:

[0056] The first step is beating treatment. The long-fiber wood pulp and short-fiber chemical-mechanical wood pulp are fully mixed and then put into the hydraulic pulper and added with water for mixing and crushing treatment. In the prize pool, two double-disc refiners are connected in series for light beating. The beating concentration is 3.5%, the beating degree is 20°, and the wet weight is 15g.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com