Benzoxazole ionic compound, PBO fiber emulsion sizing agent containing benzoxazole ionic compound and preparation method of PBO fiber emulsion sizing agent

An ionic compound, benzoxazole technology, applied in fiber treatment, fiber type, organic chemistry, etc., can solve problems such as insufficient fiber surface coverage, environmental pollution, and non-compliance with the development concept of green chemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

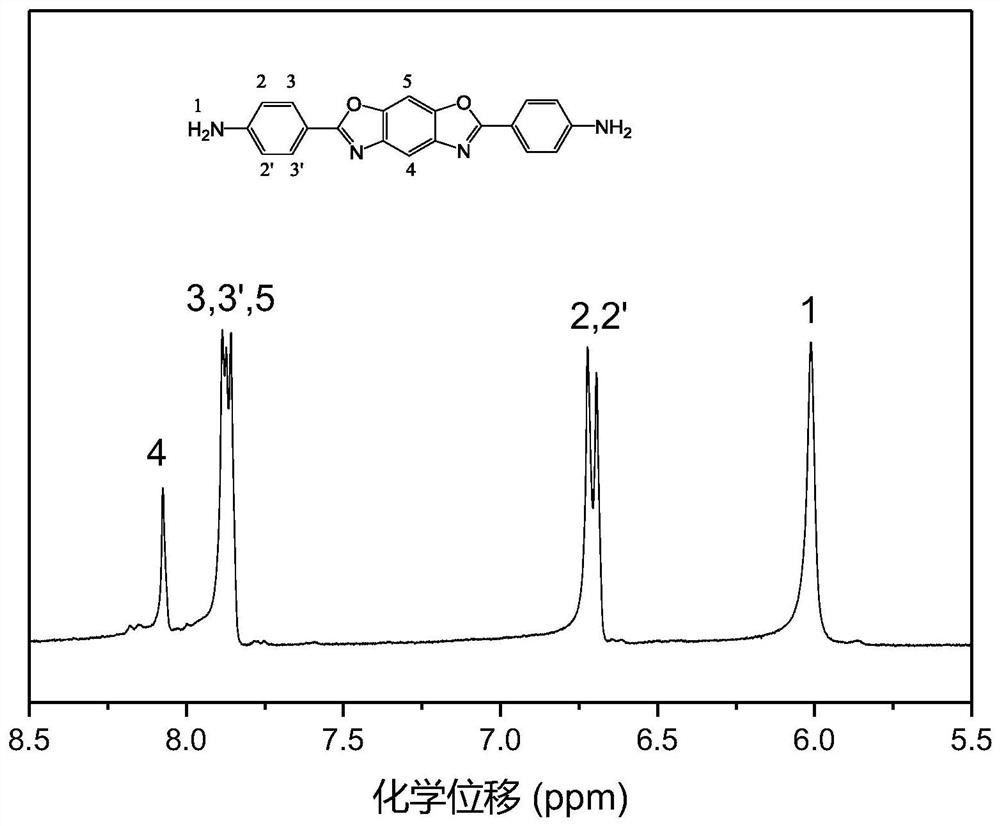

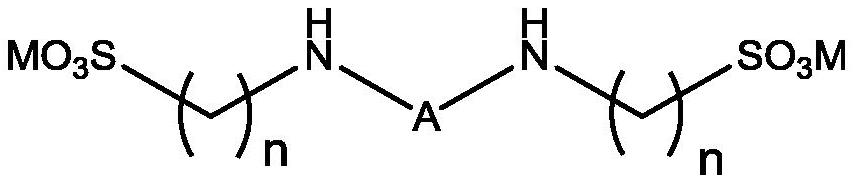

[0096] (1) 0.1mol of 4,6-diaminoresorcinol dihydrochloride, 0.2mol of 4-aminosalicylic acid and 0.01mol of stannous chloride are added to 480g of polyphosphoric acid (phosphorus pentoxide is 80wt%), N 2 Under protection, the temperature was slowly raised to 120° C., stirred for 1 h, then the temperature was raised to 150° C., and the stirring reaction was continued for 15 h to obtain a wine red transparent solution. The above solution was poured into water for precipitation, suction filtered and the filter cake was washed repeatedly with deionized water until the pH of the filtrate was close to 7.4, and dried to obtain the crude product. The crude product was recrystallized using N,N-dimethylformamide to obtain high-purity benzoxazolediamine IV-ae.

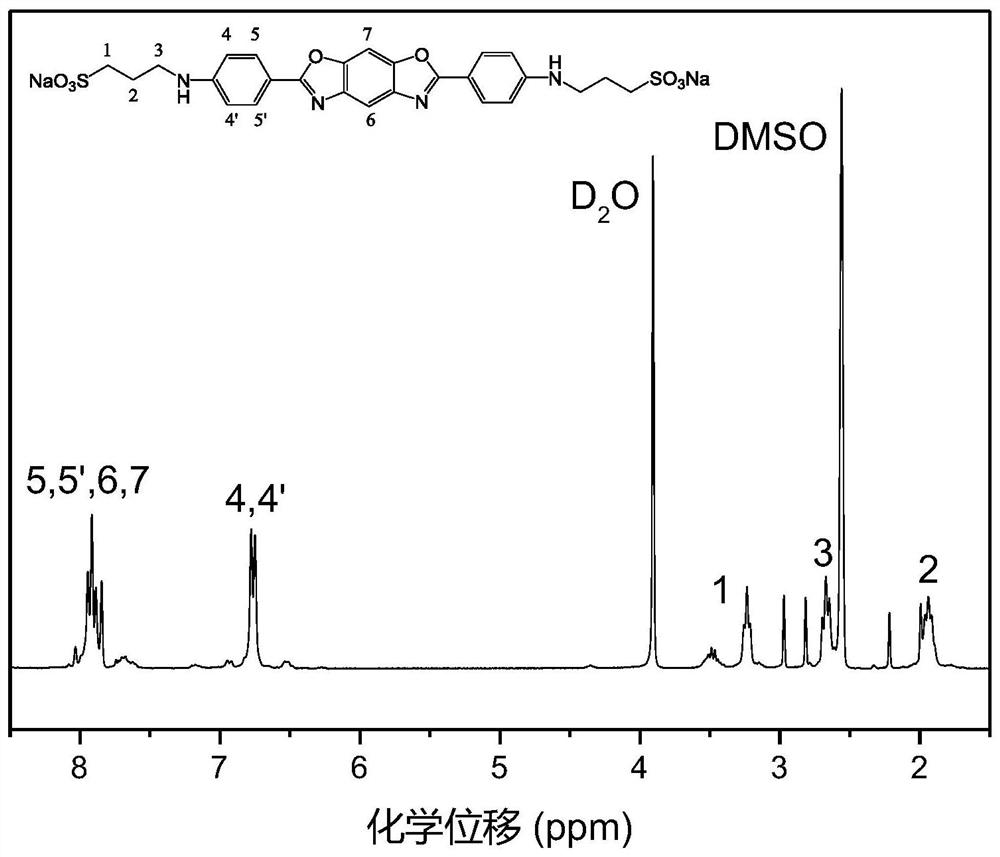

[0097] (2) Dissolve 0.1mol of IV-ae in N-methylpyrrolidone, add 0.1mol of 1,3-propane sultone, N 2 Under protection, raise the temperature of the system to 50°C, stir and react for 12 hours, pour the reactant into acetone to pre...

Embodiment 2

[0105] (1) 0.1mol of 3,3'-dihydroxybenzidine, 0.25mol of p-aminobenzoic acid and 0.03mol of stannous chloride are added in 480g of polyphosphoric acid (phosphorus pentoxide is 85wt%), N 2 Under protection, the temperature was slowly raised to 120° C., stirred for 2 h, then the temperature was raised to 200° C., and the stirring reaction was continued for 5 h to obtain a wine red transparent solution. The above solution was poured into water for precipitation, suction filtered and the filter cake was washed repeatedly with deionized water until the pH of the filtrate was close to 7.4, and dried to obtain the crude product. The crude product was recrystallized using N-methylpyrrolidone to obtain high-purity benzoxazolediamine IV-bd.

[0106] (2) Dissolve 0.1mol of IV-bd in N,N-dimethylacetamide, add 0.4mol of 1,3-propane sultone, N 2 Under protection, raise the temperature of the system to 150°C, stir and react for 3 hours, pour the reactant into acetone to precipitate, filter ...

Embodiment 3

[0112] (1) 0.1mol of 2,2-bis(3-amino-4-hydroxyl phenyl) hexafluoropropane, 0.23mol of p-aminobenzoic acid and 0.02mol of stannous chloride are added to 480g of polyphosphoric acid (penta Phosphorus oxide is 83wt%), N 2 Under protection, the temperature was slowly raised to 120° C., stirred for 1.5 h, then the temperature was raised to 180° C., and the stirring reaction was continued for 10 h to obtain a wine red transparent solution. The above solution was poured into water for precipitation, suction filtered and the filter cake was washed repeatedly with deionized water until the pH of the filtrate was close to 7.4, and dried to obtain the crude product. The crude product was recrystallized using N-methylpyrrolidone to obtain high-purity benzoxazolediamine IV-cd.

[0113] (2) Dissolve 0.1mol of IV-cd in dimethyl sulfoxide, add 0.25mol of 1,3-propane sultone, N 2 Under protection, raise the temperature of the system to 100°C, stir and react for 7 hours, pour the reactant int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com