Acetate fiber coating paper and paper filter stick for preparing cigarette filter stick and preparing method thereof

A technology for cellulose acetate and cigarette filter rods, which is applied in coatings, e-liquid filter elements, fiber raw material processing, etc., can solve the problems that are not conducive to cost reduction, reduce paper filter rods, and large amount of cellulose acetate, and achieve improved sensory evaluation. The effect of absorbing quality, reducing tar, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

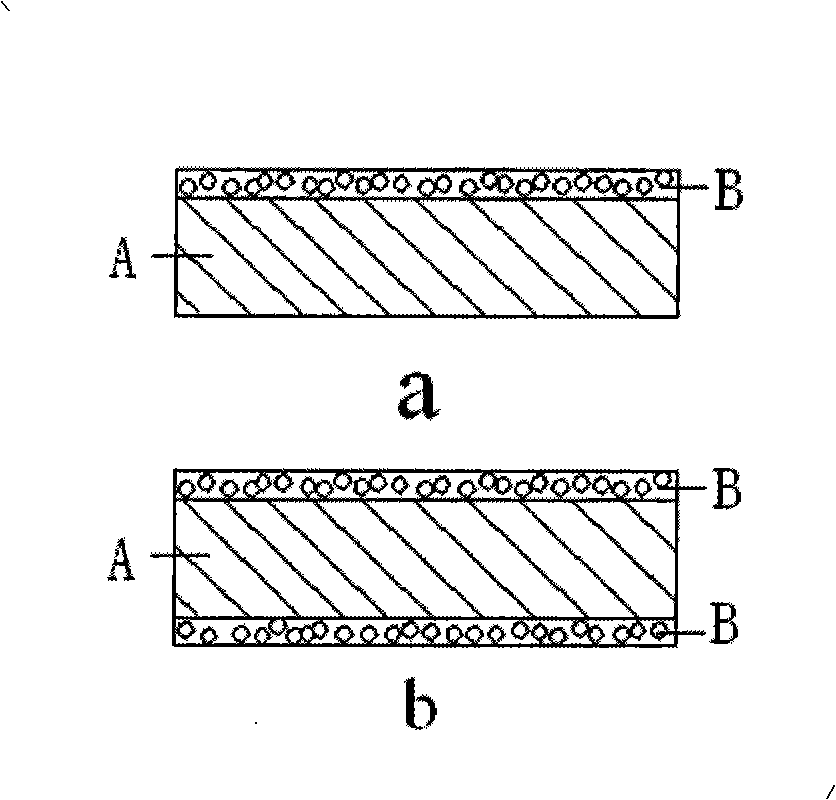

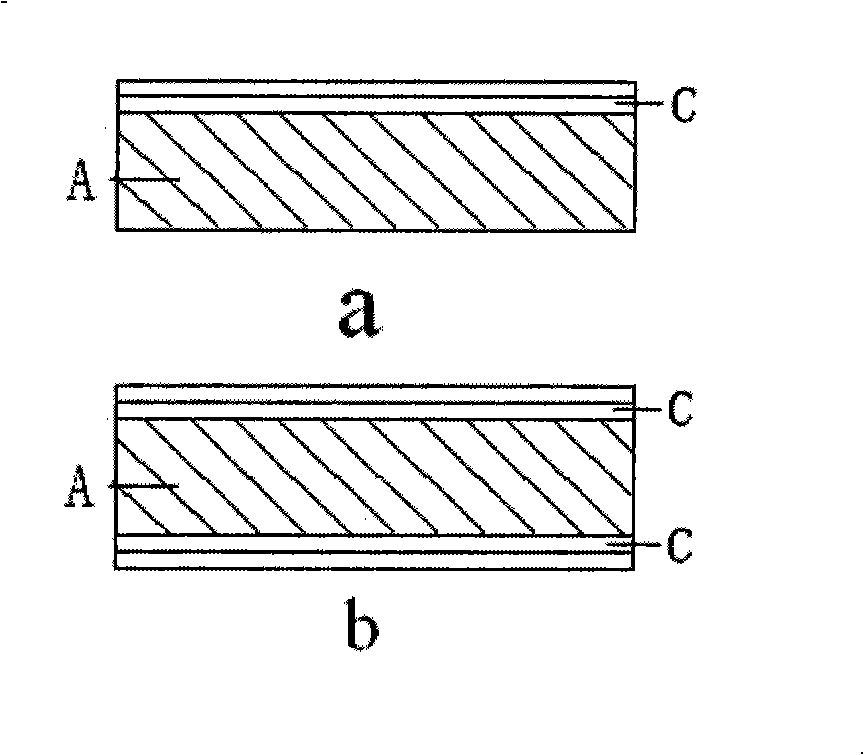

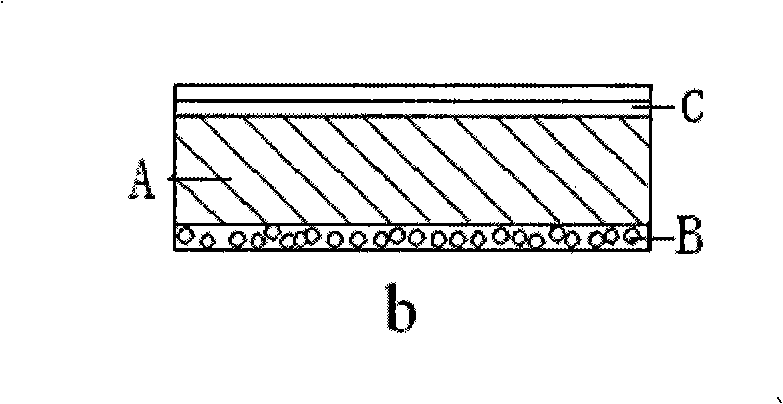

Method used

Image

Examples

Embodiment 1

[0043] Dissociate the waste yarns from the nozzle rod factory or the acetate fiber factory through disc grinding, and disperse them in the aqueous solution containing 0.8wt% modified starch. In the process of making paper with wood pulp fiber, it is coated on both sides of the paper, and the weight of acetate fiber is 12g / m 2 . The produced acetate-coated paper was embossed, cut into narrow widths of 23 cm, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment was operating normally and the taste was improved. , and the effect of reducing tar is obvious.

Embodiment 2

[0045] Dissociate the waste nozzle rods from the nozzle rod factory or the waste silk from the acetate fiber factory through disc grinding, and disperse them in the aqueous solution containing 0.5wt% polyvinyl alcohol. Coated on one side of paper made of hemp pulp fiber, the basis weight of acetate fiber is 6g / m 2 . The produced acetate-coated paper was embossed, cut into narrow widths of 22 cm, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment was operating normally and the taste was improved. , and the effect of reducing tar is obvious.

Embodiment 3

[0047] Dissolve the waste silk or cellulose acetate of the waste nozzle rod of the mouth rod factory or the cellulose acetate factory in acetone to make an acetone solution containing 5 wt% of the cellulose acetate. In the process of making paper with wood pulp fiber, it is coated on both sides of the paper, and the weight of acetate fiber is 3g / m 2 . The produced acetate-coated paper was embossed, cut into narrow widths of 26 cm, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment was operating normally and the taste was improved. , and the effect of reducing tar is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com