Ramie fiber softening method

A technology of ramie fiber and sodium hydroxide is applied in the field of textile natural fibers, which can solve the problems of affecting the comfort of clothing and reducing the moisture absorption and desorption performance of fibers, and achieve the effects of increasing moisture absorption and dehydration performance, and reducing crystallinity and modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

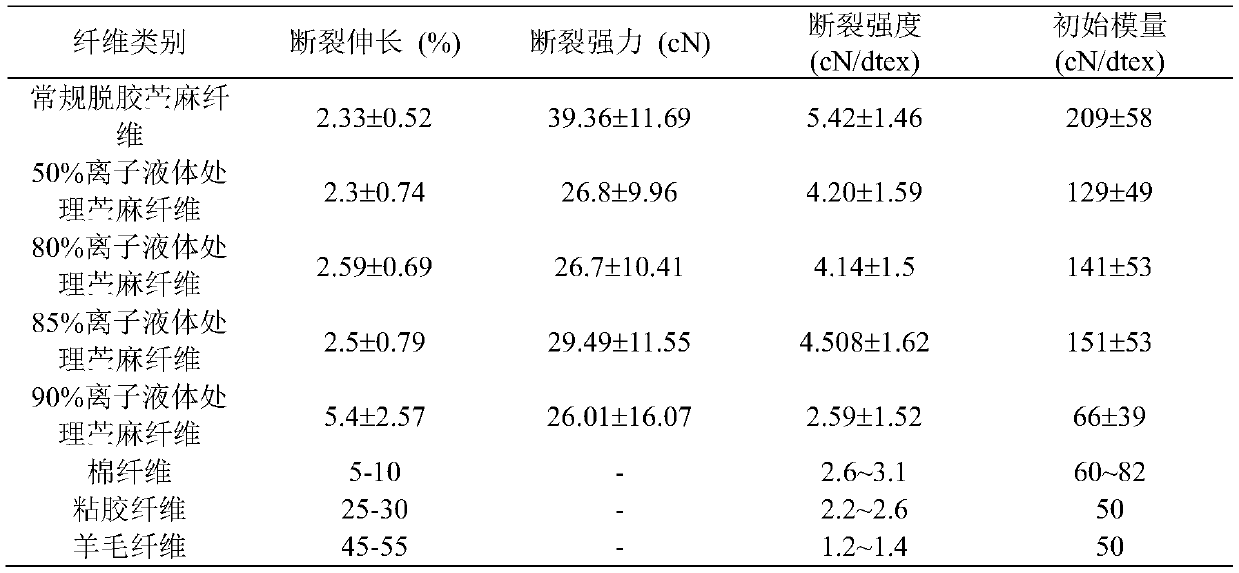

[0025] Weigh 5 g of ramie fibers, immerse the ramie fibers in a 10% sodium hydroxide solution, let stand at room temperature for 20 minutes, and make the fibers swell; then take out the fibers, put them into 100 mL of water, and gradually add a 30% acetic acid solution until The pH value is neutral; after the fiber is cleaned with 60 ℃ of pure water, freeze-drying 24h is used in a freeze dryer; finally the ramie fiber is taken out, immersed in 50%, 80%, 85%, 90% ionic liquid (milk file ) using ultrasonic treatment for 15-30 minutes; washing and drying to obtain softened ramie fibers. The physical and mechanical properties of the finally obtained fibers are shown in Table 1.

[0026] Table 1 Comparison of physical and mechanical properties of ramie fiber obtained under different treatment conditions and conventional fiber physical and mechanical properties

[0027]

[0028] The above experimental results show that after the ramie fiber is treated by the technical solution, ...

Embodiment 2

[0030] Weigh 5 g of ramie fiber, immerse the ramie fiber in a 5% sodium hydroxide solution, and let it stand at 15°C for 30 minutes to make the fiber swell; then take out the fiber, put it in water, and gradually add hydrochloric acid solution to neutralize the fiber sodium hydroxide until the pH value is neutral; then the ramie fibers are washed in hot water, the ramie fibers are taken out from the aqueous solution, drained, and freeze-dried for 10 hours using a freeze dryer to freeze-dry the moisture inside the fibers; Immerse the freeze-dried ramie fiber in ionic liquid (milk file) with a mass concentration of 70%, and ultrasonically treat it for 30 minutes; wash and dry the treated ramie fiber to obtain softened ramie fiber.

Embodiment 3

[0032] Weigh 5 g of ramie fiber, immerse the ramie fiber in a sodium hydroxide solution with a mass concentration of 20%, and let it stand at 30°C for 10 seconds to make the fiber swell; then take out the fiber, put it in water, and gradually add acetic acid solution to neutralize the fiber sodium hydroxide until the pH value is neutral; then the ramie fibers are put into pure water for cleaning, the ramie fibers are taken out from the aqueous solution, drained, and freeze-dried for 10 hours using a freeze dryer to freeze-dry the moisture inside the fibers; The freeze-dried ramie fibers are immersed in an ionic liquid (milk file) with a mass concentration of 90%, and ultrasonically treated for 15 minutes; the treated ramie fibers are washed and dried to obtain softened ramie fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com