Patents

Literature

36results about How to "Improve moisture absorption and release performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

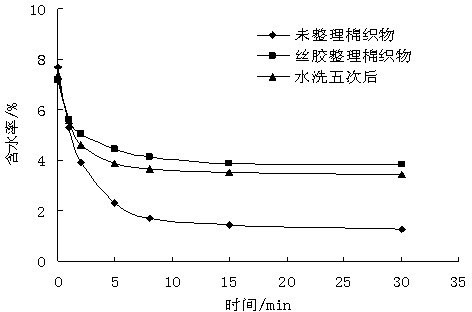

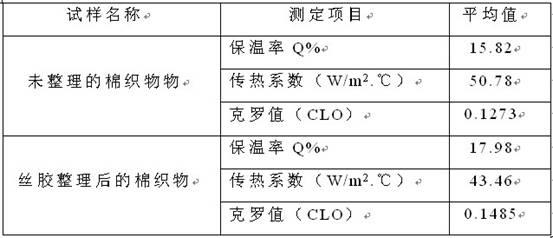

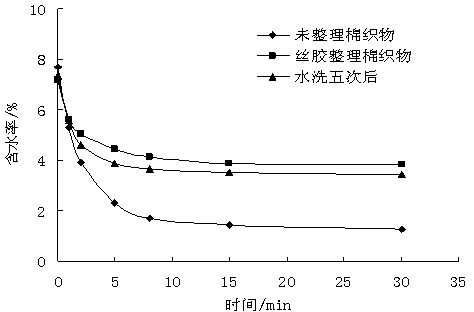

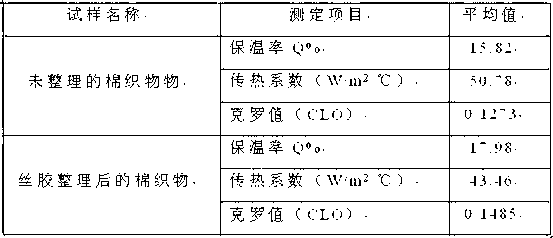

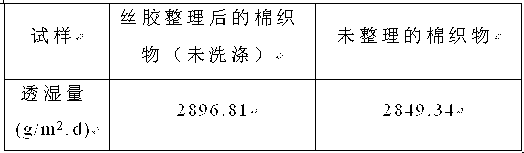

Sericin post-finishing method for cotton fabrics

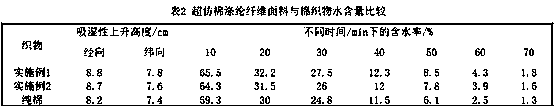

The invention discloses a sericin post-finishing method for cotton fabrics, which comprises the following steps: (a) configuring settling impregnation liquid: dissolving 3-5% of dissolvable sericin powder counted by mass in hot water, and then adding 1-3% of chitosan quaternary ammonium salt, fully stirring and dissolving, and adding 4-6% of cross-linking agent, and (b) completely steeping the cotton fabrics in the settling impregnation liquid at a solution bath ratio of 1:(30-50), steeping for at least 20 minutes, twice steeping and twice rolling, keeping mangle expression more than 80%, anddrying, thereby obtaining the cotton fabrics. The invention develops the post-finishing method special for the cotton fabrics. The cotton fabrics prepared according to the post-finishing method have better washing fastness and anti-bacteria rate; after the cotton fabrics are washed for five times, a dissolving loss rate is about 0.21% and the anti-bacteria rate is 93.8%; the practical use requirement is fully met; and an extraordinary technical effect is obtained.

Owner:NANTONG LOVER APPL

Moisture-absorbing and desorbing polymer and compositions derived therefrom

InactiveUS20020010295A1Improve moisture absorption and release performanceHigh propertyOther chemical processesDispersed particle separationPotassiumMoisture

Owner:JAPAN EXLAN CO LTD

Composite cellulose viscose filament yarn with composite cellulose pulp as raw materials made of cotton, wood, hemp and bamboo mixture, and preparation method thereof

InactiveCN1865547AShinyGood air permeabilityConjugated cellulose/protein artificial filamentsSpinning solutions preparationManufacturing efficiencyNatural fiber

The invention discloses a composite fiber viscose filament and preparing method, which adopts the following random two or more combination as raw material: cotton velvet, hemp, wood, bamboo, straw and crust. The preparing method comprises the following steps: blending pulp; immersing; squeezing; grinding; etiolating; adhering glue to grind; dissolving; grinding; filtering; ripening; debubbling; spinning; refining; drying to make cylinder. The invention reduces cost to improve manufacturing efficiency with excellent paintability, elasticity, desiccating and air permeability, which is better than kinds of synthesizing fiber.

Owner:YIBIN GRACE

Moisture-absorbing and desorbing polymer and compositions derived therefrom

InactiveUS6429265B2Improve moisture absorption and release performanceHigh propertyOther chemical processesDispersed particle separationPolymer sciencePOLYMER SUBSTANCE

Owner:JAPAN EXLAN CO LTD

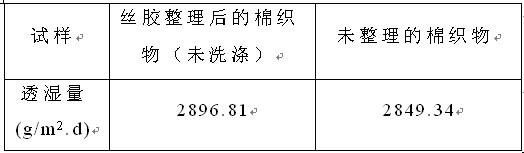

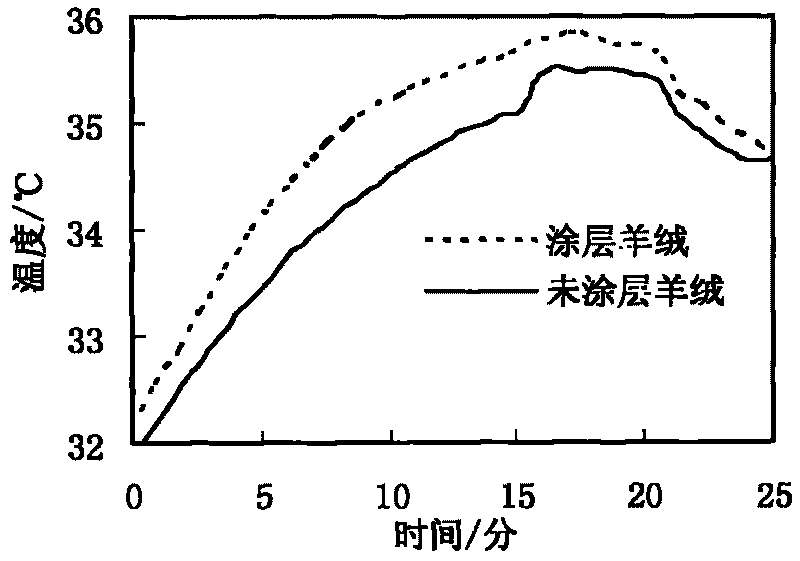

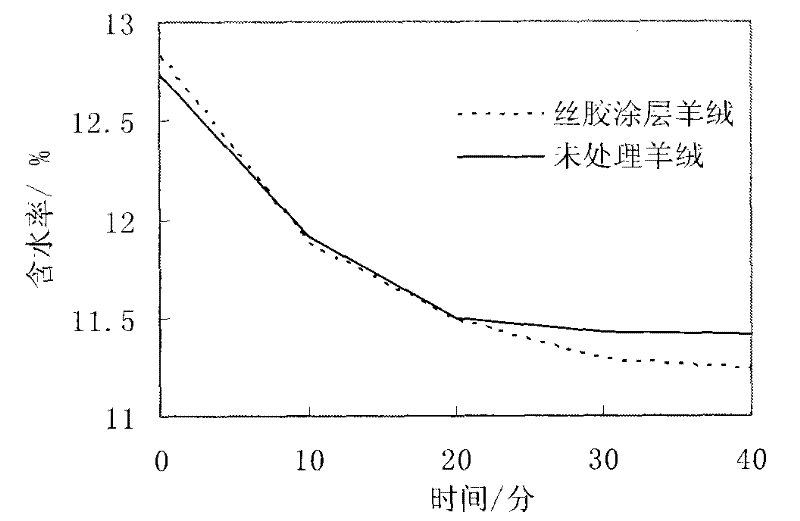

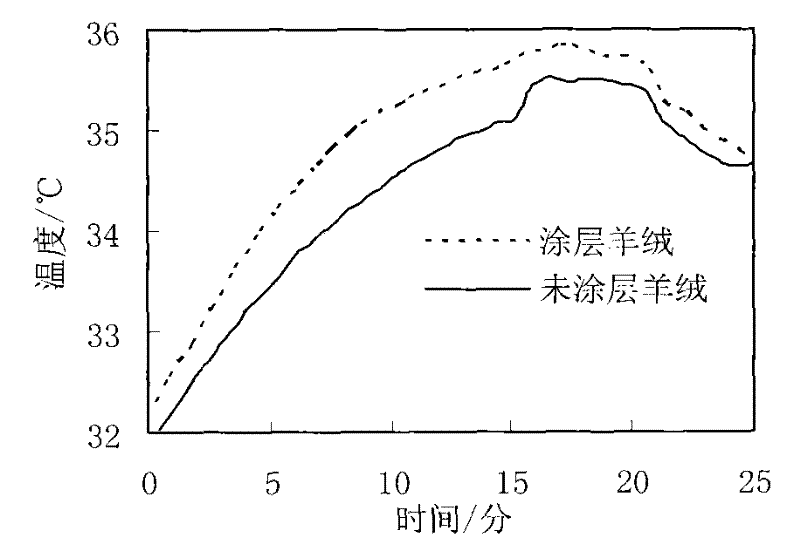

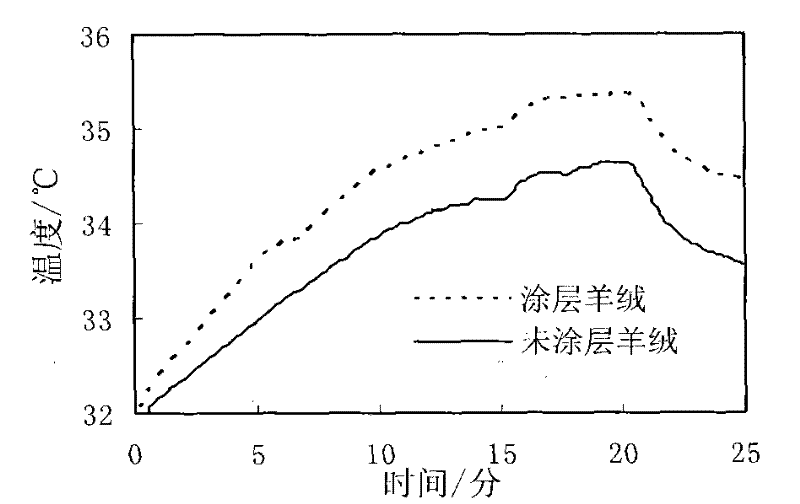

After finishing method for sericin of cashmere product

Owner:苏州盛泽科技创业园发展有限公司

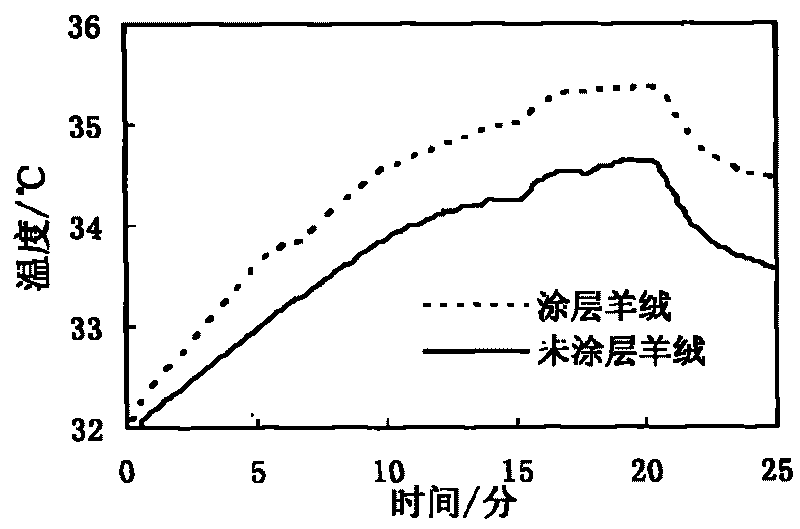

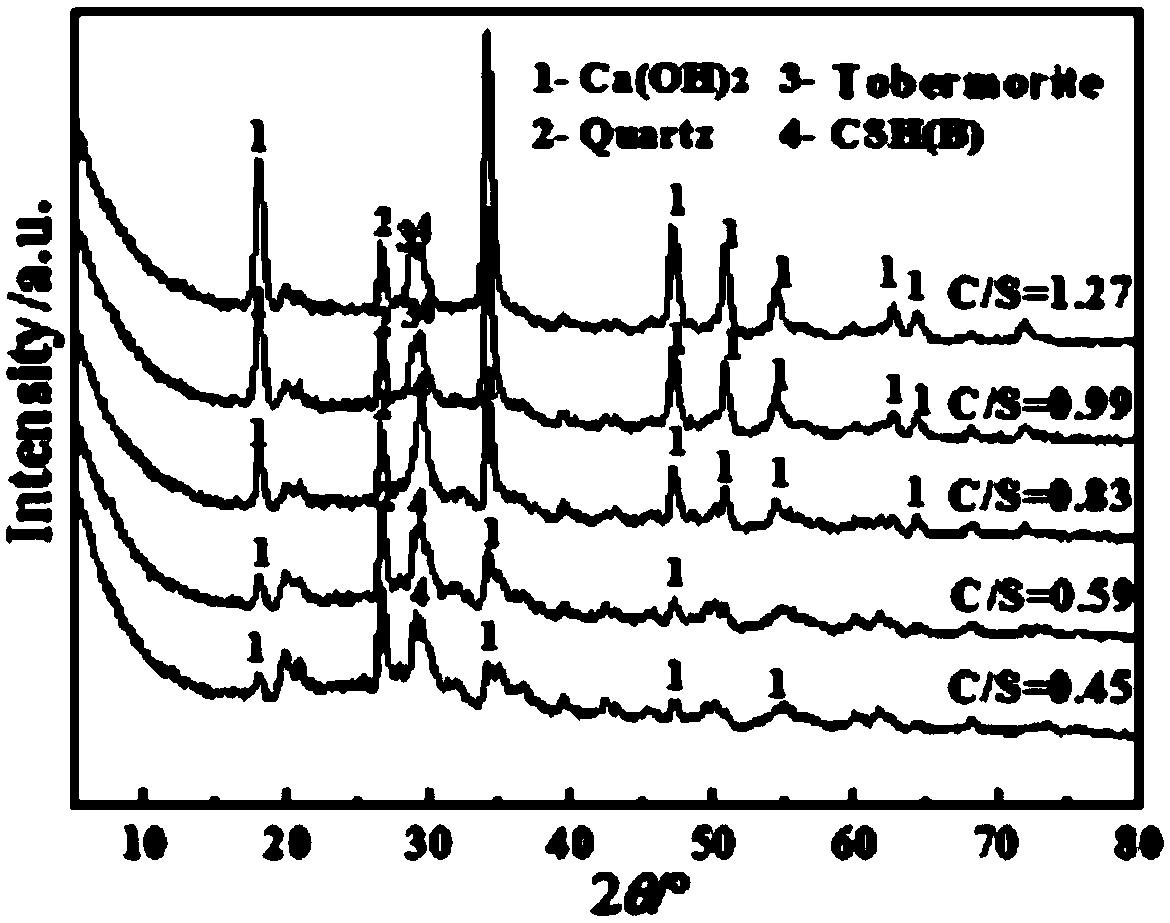

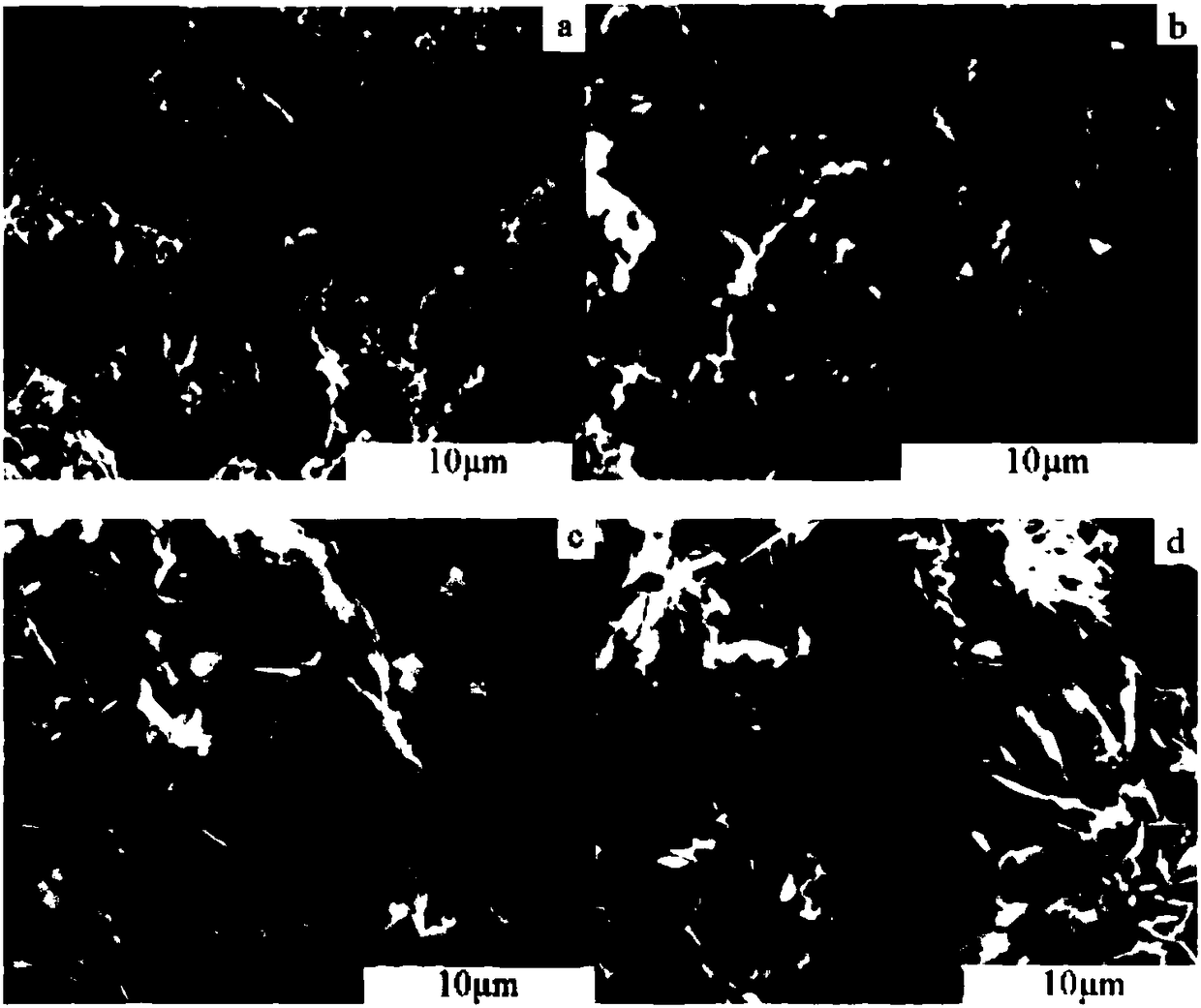

Preparation method of diatom-based hydrated calcium silicate powder moisture regulating material

InactiveCN108262003AImprove moisture absorption and release performancePreserve pore structure featuresOther chemical processesCalcium silicateCalcium in biology

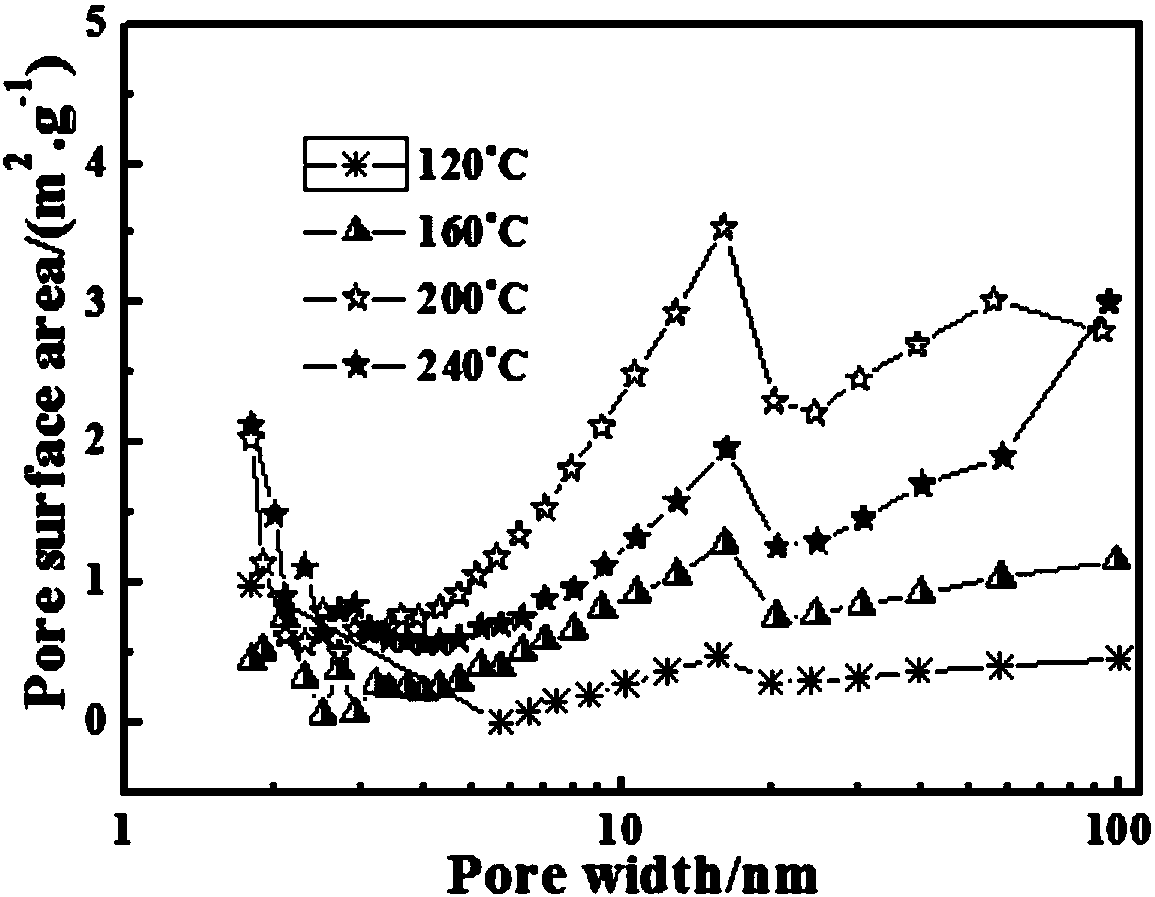

The invention relates to the field of inorganic functional powder, in particular to a preparation method of a diatom-based hydrated calcium silicate powder moisture regulating material. Diatomaceous earth serves as a natural mineral raw material and is subjected to a combination reaction with calcium raw materials and water in high-temperature saturated steam to form the powder moisture regulatingmaterial with hydrated calcium silicate as a main component. The method is characterized by comprising the steps that (1) diatomaceous earth and the calcium raw materials are matched and evenly mixedaccording to a certain proportion, mixing water the mass of which is 20-50% of that of the dry materials is added, and mixing continues to be conducted until the materials are completely uniform; (2)the reaction mixture is subjected to a hydrothermal reaction in the saturated steam environment at 120-240 DEG C for 2-24 hours; (3) an obtained sample is dried and moderately ground to obtain the diatom-based hydrated calcium silicate powder moisture regulating material. By means of the method, the powder material with hydrated calcium silicate as the main component can be obtained, the abundantmesoporous structure of diatomaceous earth can be reserved to a certain extent, the powder material is endowed with the considerable moisture absorption and desorption capacity accordingly, and the moisture regulating performance is excellent.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation method of spherical composite humidity-controlling material

InactiveCN102964763AIncrease wet capacityImprove humidity control performanceAluminium chlorideHalloysite

The invention relates to a preparation method of a spherical composite humidity-controlling material, which comprises the following steps of: a. activating halloysite for 2-3 hours to obtain activated halloysite; b. adding polyacrylic acid into a sodium hydroxide solution obtained by mixing sodium hydroxide with distilled water for neutralization, respectively adding konjac glucomannan, the activated halloysite, potassium peroxodisulfate, N, N'-methylene bisacrylamide and a aluminum chloride solution obtained by mixing aluminum chloride and water into a reactor filled with the neutralized solution, and stirring for reaction; c. adding sodium bicarbonate into the reactor to generate aluminum hydroxide and carbon dioxide, carrying out primary foaming, and stirring for reaction to obtain a synthetic product; d. drying the synthetic product at 80 DEG C and shearing the block synthetic product into small cubic pieces; and e. heating at the temperature of 150 DEG C to decompose aluminium hydroxide and evaporate water, carrying out secondary foaming and drying to obtain the spherical composite humidity-controlling material. The spherical composite humidity-controlling material is simple and convenient to prepare, low in cost, good in effect, environment-friendly and free from pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Sericin post-finishing method for cotton fabrics

ActiveCN102605619BImprove washabilityGood antibacterial effectVegetal fibresPolymer scienceSILK SERICIN

Owner:NANTONG LOVER APPL

Preparation method of high-efficiency compound humidity-controlling paperboard

InactiveCN102966005AIncrease wet capacityImprove humidity control performanceSpecial paperPaper/cardboardSODIUM PYRROLIDONE CARBOXYLATEPaperboard

The invention provides a preparation method of high-efficiency compound humidity-controlling paperboard, comprising the following steps: a-f, preparing humidity-controlling resin per se for later use; g, adding 0.1 part of sodium carboxymethylcellulose into 5 parts by weight of water, stirring till the sodium carboxymethylcellulose is evenly dispersed in the water, and stewing to enable the sodium carboxymethylcellulose and the water to be infiltrated and fused with each other to form into pasty glue solution for later use; h, adding 0.5 part by weight of kieselguhr, 2.5 parts by weight of L-pyrrolidone carboxylic acid-Na, 0.3 part by weight of sodium chloride and 2.7 parts by weight of anhydrous potassium carbonate into 100 parts by weight of water, and stirring to be dissolved; i, taking 4.25 parts by weight of dry paper pulp, adding the paper pulp and the pasty glue solution obtained in step g into mixed solution obtained in step h, and pulping for 2min; j, adding 1.7 parts by weight of the humidity-controlling resin obtained in step f into the mixture obtained in step i, and stirring by a stirrer; and k, papermaking, and drying under the temperate of 80-100 DEG C for 5-7h. The paperboard is very convenient to regenerate and reuse; and the preparation method is simple in production technology and equipment, and easy to industrialize.

Owner:ZHEJIANG SCI-TECH UNIV

Cellulose fiber blended fabric

ActiveCN101374991AEasy to useComfortable to wearWeft knittingOrnamental textile articlesCellulose fiberEngineering

It is intended to provide a fabric which is comfortable for a wearer and shows neither stickiness nor stuffiness in sweating. The above object can be achieved by a cellulose fiber blended fabric characterized by containing cellulose fiber having a dimensional change rate upon water absorption of 2% or above. When employed in sport wears, inners, outers and so on, this fabric can give comfortableness to wears.

Owner:ASAHI KASEI ADVANCE CORP

Black high wet absorption and discharging fibre

InactiveCN1408937AExcellent blackness stabilityUnlimited useFibre typesGas discharge lampsCross-linkPolymer science

To provide a highly moisture-absorbing / desorbing black fiber having excellent processability and more excellent blackness stability than conventional fibers, while having moisture-absorbing / desorbing properties, heat-generating properties due to moisture absorption, and light-to-heat converting properties. SOLUTION: This highly moisture-absorbing / desorbing black fiber is made of a carbon black-containing acrylic fiber into which cross-links are introduced by using a hydrazine-based compound and carboxylic groups are introduced by being hydrolyzed and, if necessary, of which the ratio of protons of the carboxylic groups to metal salts is controlled, so that the fiber has a saturated moisture absorption rate of >=10 wt.%, a dry strength of >=0.8 cN / dtex, and a lightness (L-value) of <=35.

Owner:JAPAN EXLAN CO LTD

Composite building humidity-controlling material and preparation method thereof

InactiveCN107876026AHas the ability to absorb and release moisture automaticallyLarge pore volumeOther chemical processesComposite effectClay minerals

The invention relates to a composite building humidity-controlling material and a preparation method thereof, and belongs to the technical field of building materials. The humidity-controlling material is prepared from quaternized chitosan modified sepiolite to be compounded with sierozem, ground calcium carbonate, quartz sand and attapulgite. A great number of detrital impurities such as carbonaceous matters, clay minerals and the like covered on the surface of the sepiolite are removed through acidification and purification, so that most of pore structures appear, the pore volume of the sepiolite is obviously increased, and the moisture absorption and release ability of the sepiolite is enhanced. Meanwhile, chitosan is subjected to quaternization modification, so that the moisture absorption is improved. During the cleaning process of pores of the sepiolite, the pores are filled with the chitosan to produce a composite effect with porous structures of the sepiolite, so that the diffusion performance of water vapor on the surface of the material or inside the material is improved, the capillary condensation of the water vapor inside the material is promoted, and the moisture absorption capacity of the material is increased. The humidity-controlling material has faster moisture absorption and release rate, so that the physical adsorption of the material to moisture is promoted,and the moisture absorption capacity is increased to further enhance the moisture absorption and release ability.

Owner:吴刚

Anti-fatigue collagen cashmere composite fabric and manufacturing method thereof

InactiveCN106637486AMitigating the problem of year-on-year declineImprove hydrophilicityCarbon fibresInorganic material artificial filamentsCarbon nanotubeOxygen

The invention discloses an anti-fatigue collagen cashmere composite fabric, which is prepared from the following raw materials in parts by weight: 41 to 45 parts of cashmere fiber, 10 to 12 parts of rabbit hair, 15 to 17 parts of germanium fiber, 12 to 14 parts of grey bamboo charcoal fiber, 8.5 to 9.5 parts of pure collagen powder, 2.5 to 3.5 parts of ethylene glycol diglycidyl ether, 0.5 to 0.8 part of zinc stearate, 7 to 8 parts of coffee grounds, 1.3 to 1.5 parts of pregelatinized starch, 1.8 to 2.3 parts of carbon nanotube particle, 2 to 3 parts of tricresyl phosphate, 1.1 to 1.4 parts of aminopropyl triethoxysilane, 195 to 198 parts of 1-allyl-methyl imidazole chloride, and a proper amount of water. A oxygen low temperature plasma is used to carry out pretreatment, then ethylene glycol diglycidyl ether is taken as a crosslinking agent so as to graft modified collagen onto the surface of cashmere composite fibers, and the obtained cashmere composite fabric can be used to produce bedclothes having an anti-fatigue function.

Owner:ANHUI TIANWEI CASHMERE PROD

Warm collagen and cashmere composite fabric with high thermal stability and production method thereof

InactiveCN106637909AEnhance moisture absorption and releaseImprove hydrophilicityPhysical treatmentBiochemical fibre treatmentWoolOxide

The invention discloses warm collagen and cashmere composite fabric with high thermal stability. The fabric is formed by the following materials in parts by weight: 40-43 parts of cashmere fibers, 16-18 parts of kapok fibers, 13-16 parts of polycarbonate fibers, 8.6-8.9 parts of pure collagen powder, 2.6-2.9 parts of ethylene glycol diglycidyl ether, 6-7 parts of lotus leaves, 1-2 parts of volcanic mud, 2-3 parts of polyving akohol, 0.7-0.9 part of lentinan, 2.6-2.9 parts of nanometer ferroferric oxide, 1.1-1.3 parts of vinyl trimethoxy silane, 188-192 parts of 1-allyl-3-methylimidazole chloride and a proper amount of water. According to a production method of the fabric provided by the invention, oxygen low-temperature plasma is used for pre-processing, and then the ethylene glycol diglycidyl ether is used as a cross-linking agent for grafting the modified collagen onto the surfaces of cashmere composite fibers. The produced cashmere composite fabric has the characteristics, such as being stiff, smooth and elegant, of original wool spinning products, and also has the performance of keeping warm and protecting health.

Owner:ANHUI TIANWEI CASHMERE PROD

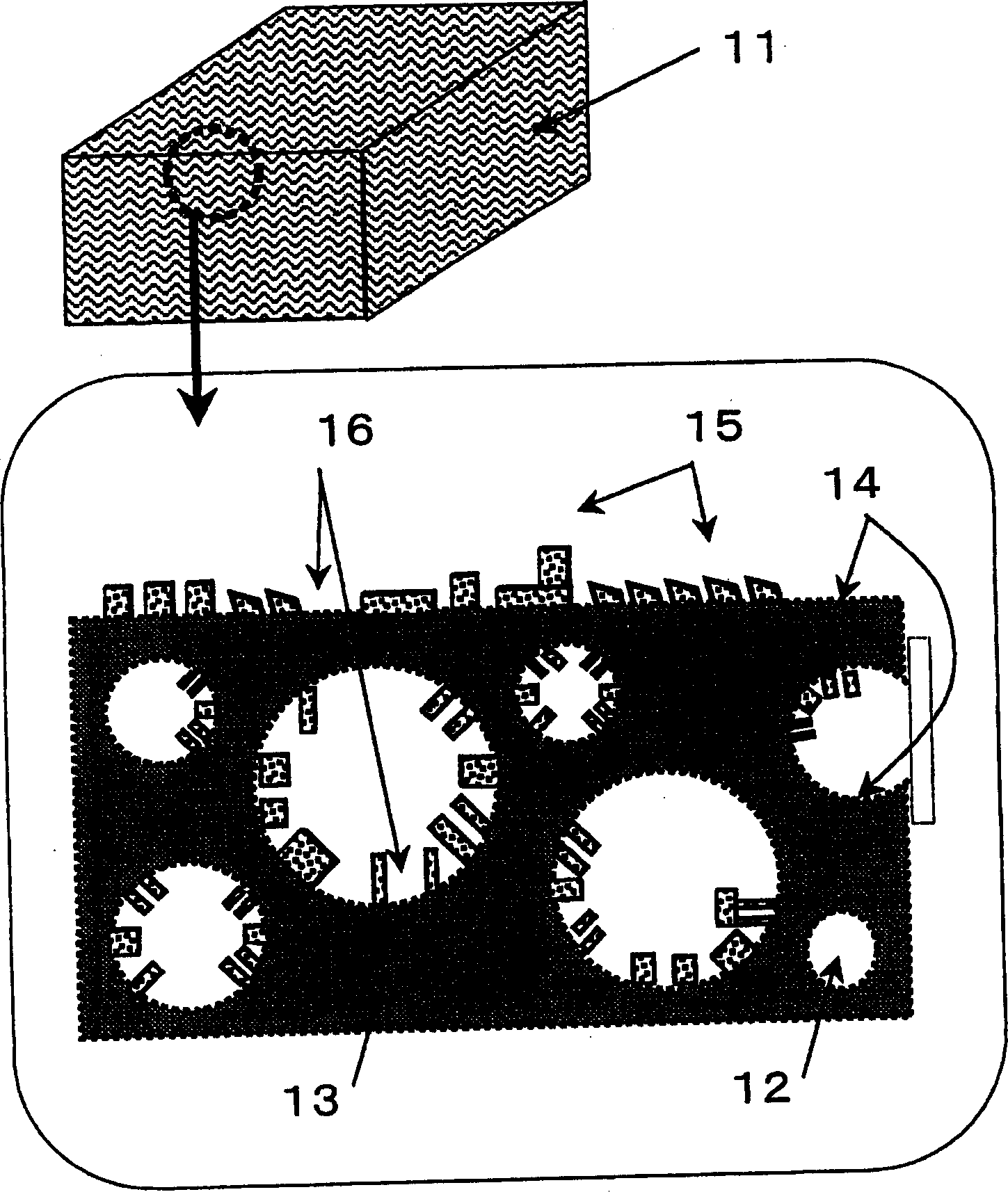

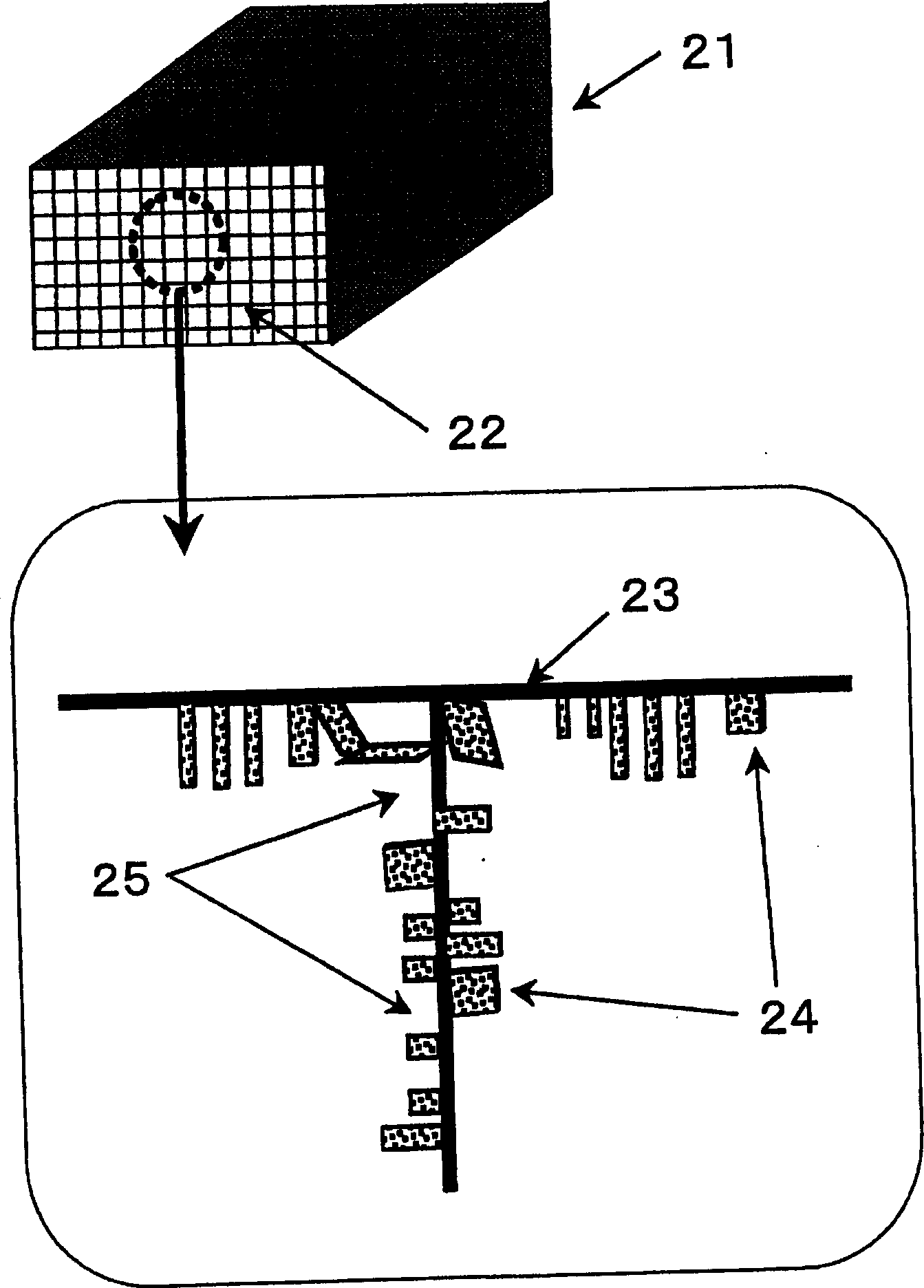

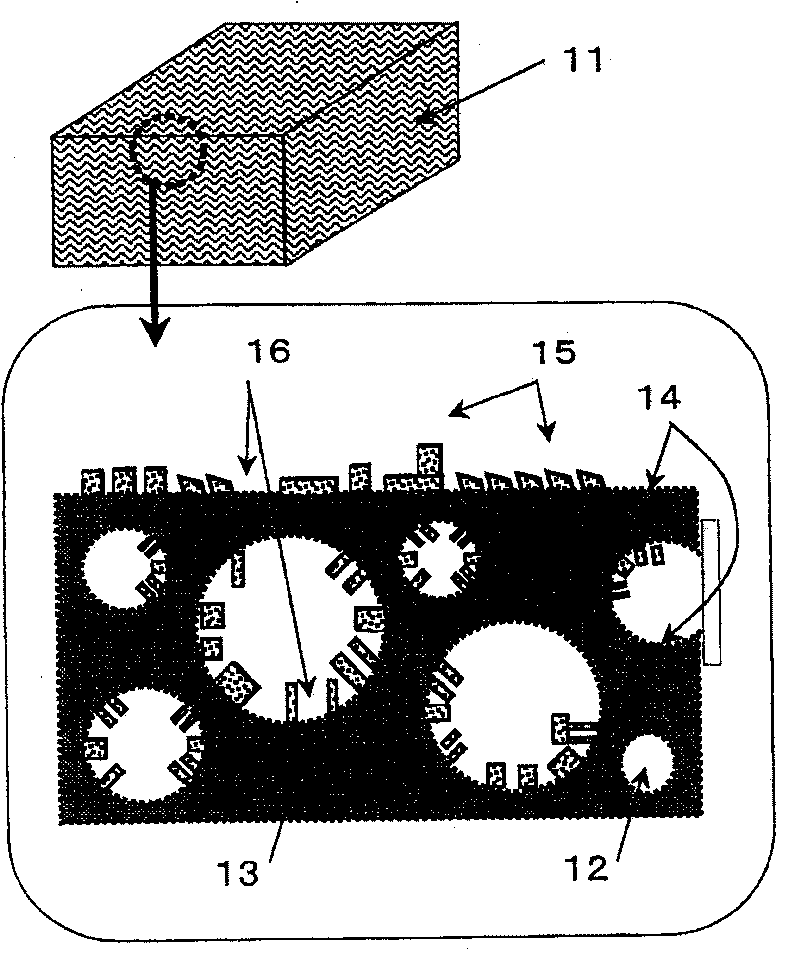

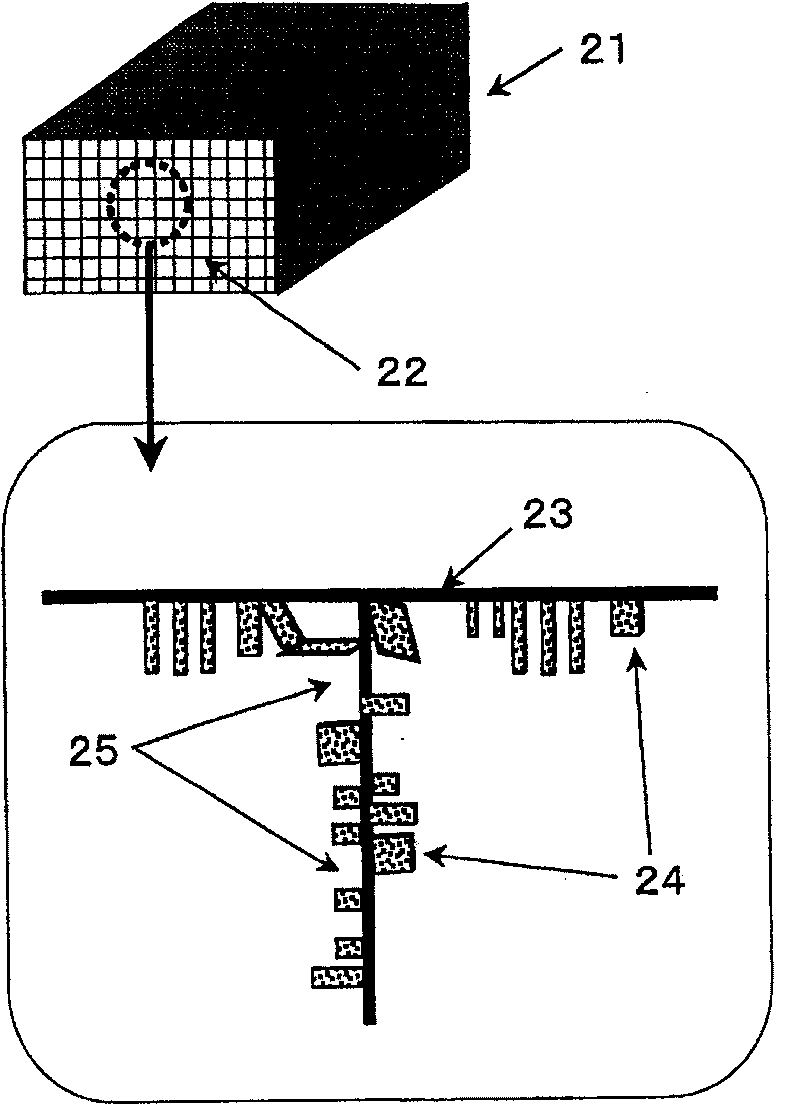

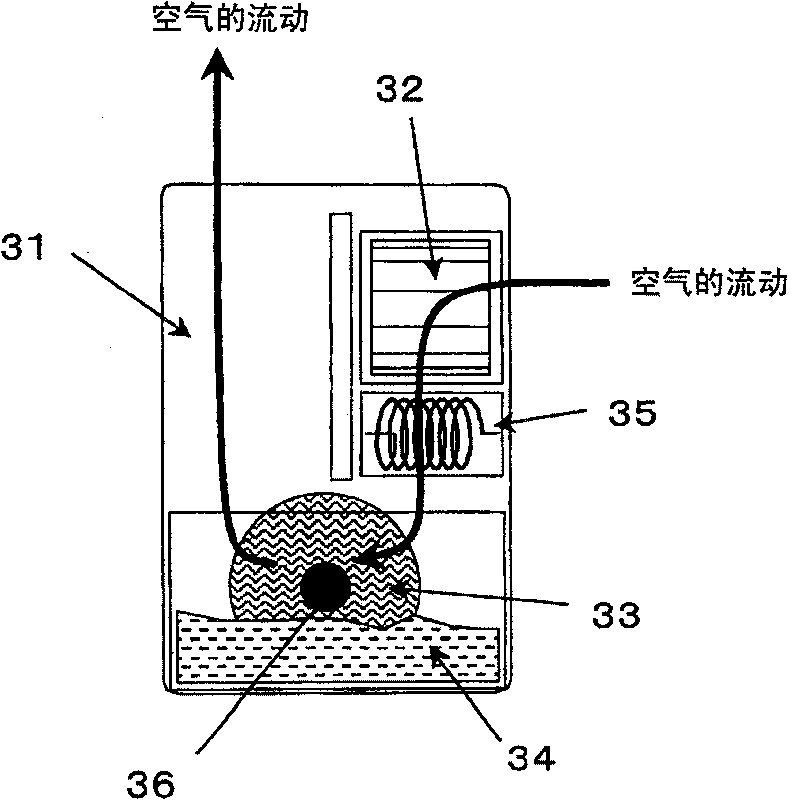

Absorb-discharge humid filter and humidifying apparatus

ActiveCN1808004AImprove moisture absorption and release performanceLighting and heating apparatusAir humidification systemsDesorptionEngineering

The present invention provides a humidifying device for use in a humidifying room that maintains humidifying capability even if precipitates are generated on a hygroscopic filter, and is maintenance-free for long-term use. Inorganic material (15) with a particle size of 2 μm to 55 μm is loaded on the base material (13) with air gaps (12), and the moisture absorption and desorption filter (11) whose surface is processed into unevenness (16) is due to the absorption and desorption of the surface. The hygroscopicity and desorption are good, and there is no need to absorb water by capillary action, so it is possible to provide a moisture absorbing and desorbing filter (11) that reduces the decrease in humidification capacity due to the adsorption of minerals. In addition, by using the moisture absorption and desorption filter (11), the moisture absorption and desorption filter (11) and the humidifying device are provided without maintenance for long-term use.

Owner:PANASONIC CORP

Method for manufacturing breathable moisture absorption modified polyester fibers

ActiveCN102400247AHigh hygroscopicityShort response timeMonocomponent polyesters artificial filamentArtifical filament manufactureSodium polyacrylateSodium carboxymethylcellulose

The invention discloses a method for manufacturing breathable moisture absorption modified polyester fibers. The method comprises the following steps of: A) adding sepiolite into a 2 mass percent hydrochloric acid solution in a mass ratio of 1: (6-10), stirring for 0.5 to 1.5 hours, dehydrating and drying, and thus obtaining activated sepiolite; B) adding the activated sepiolite into a 4 mass percent cetyl trimethyl ammonium bromide solution in a mass ratio of 1: (4-6), stirring for 2 to 3 hours, drying, and thus obtaining organic sepiolite; C) taking 0.1 to 0.5 mass parts of glycol diglycidyl diethyl ether, 0.5 to 1.5 mass parts of sodium carboxymethylcellulose, 4 to 6 mass parts of sodium polyacrylate, 0.05 to 0.15 mass part of potassium persulfate, 1 to 3 mass parts of organic sepiolite and 6 to 10 mass parts of water, performing stirring reaction for 1 to 3 hours at the temperature of between 70 and 90 DEG C, drying, grinding, and thus obtaining a modified functional material, thegrain diameter of which is not more than 15 microns; and D) adding 5 to 15 parts of functional material into 85 to 95 parts of polyester melt, uniformly mixing the functional material into the polyester melt with high-speed stirring, and spinning by using a spinneret plate with 'cross' special-shaped holes.

Owner:扬州富威尔复合材料有限公司

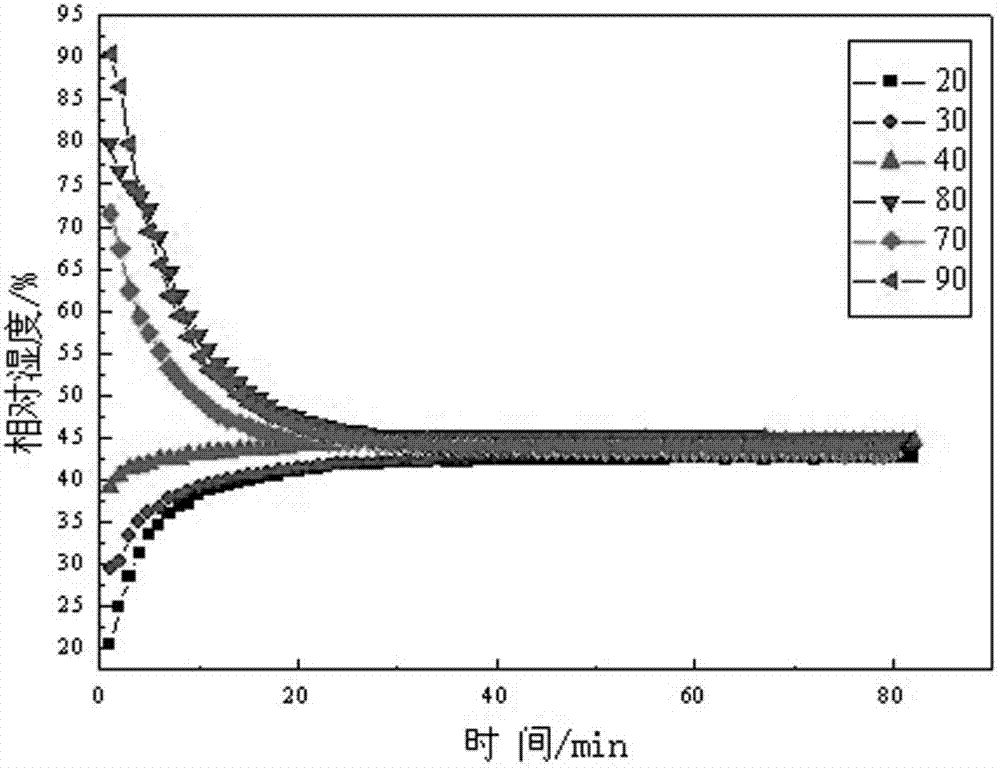

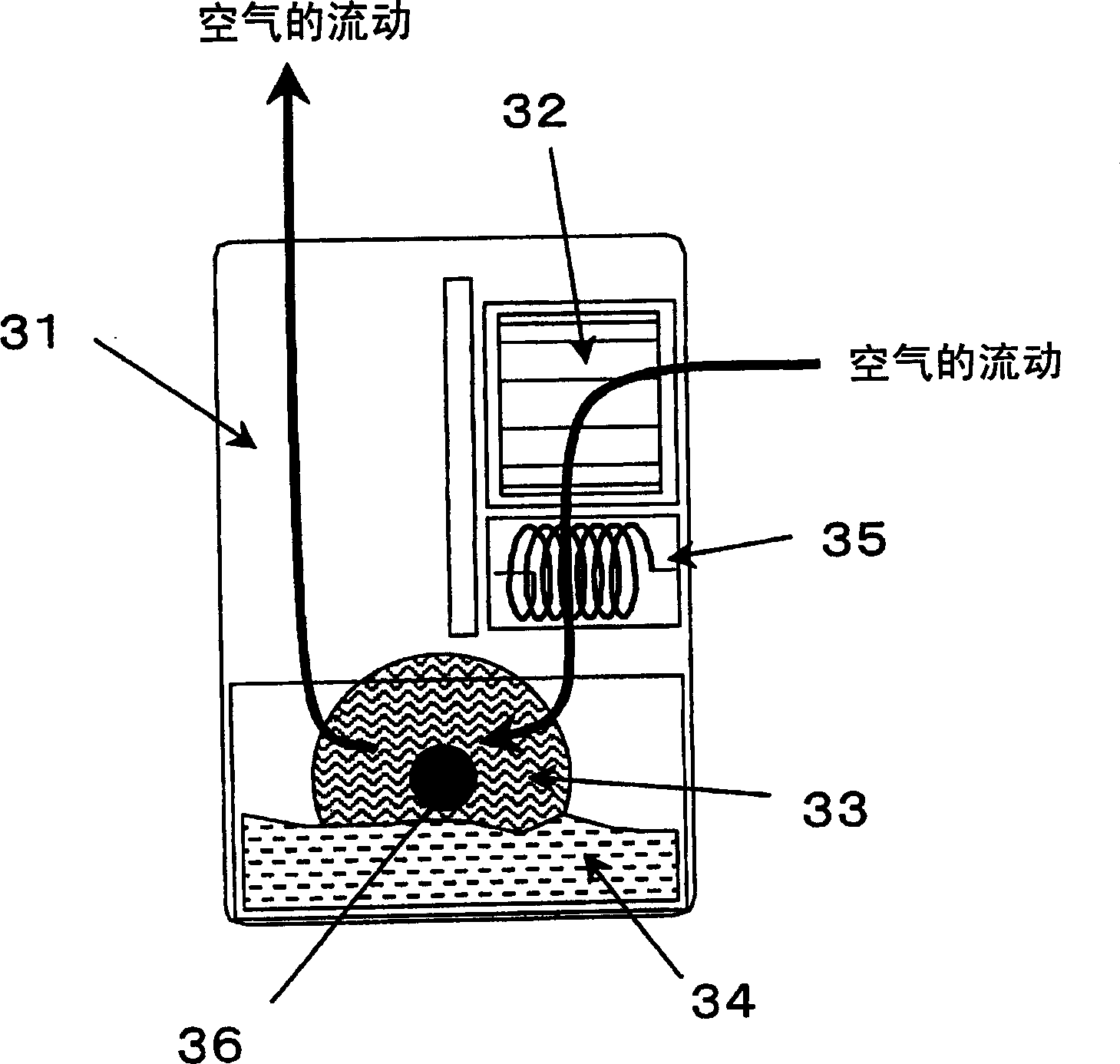

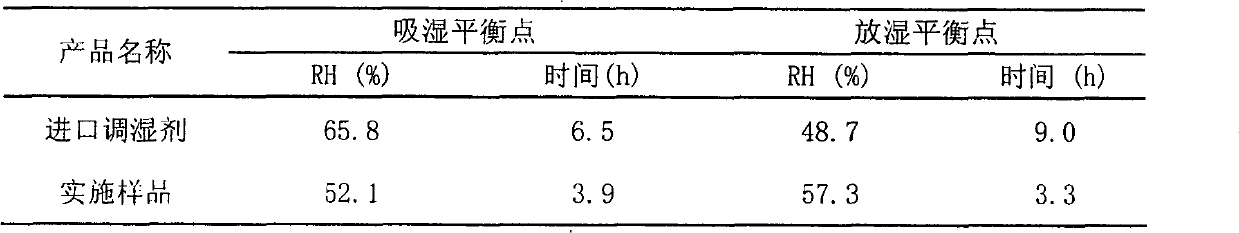

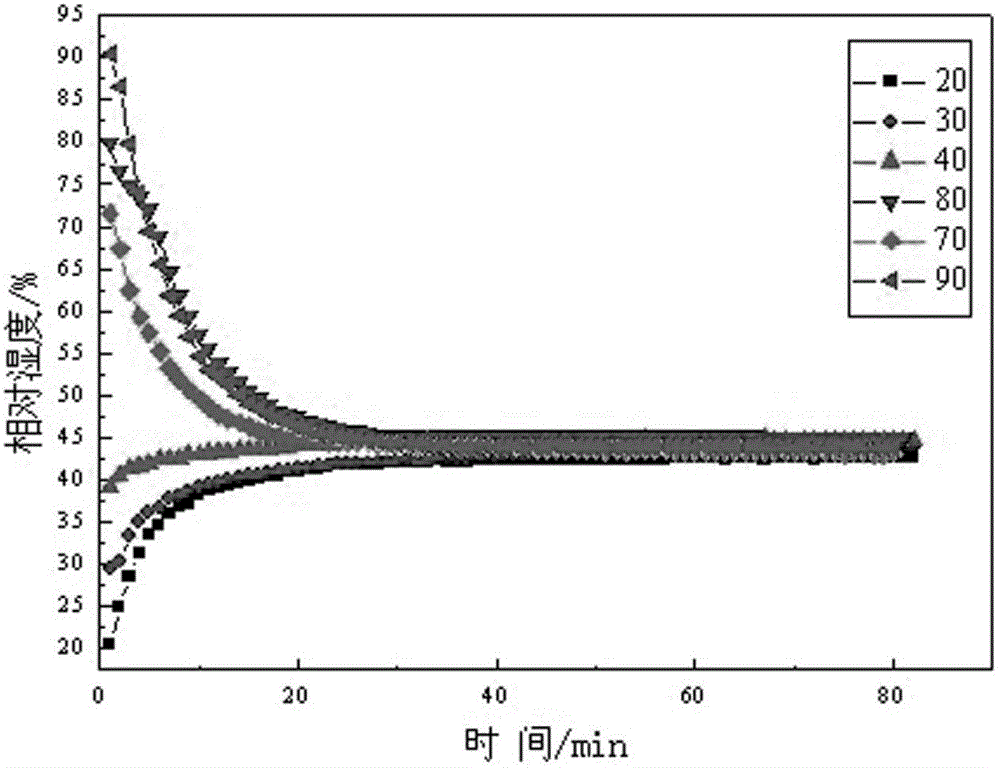

Alternate humidity control method for energy-saving cultural relic cabinet

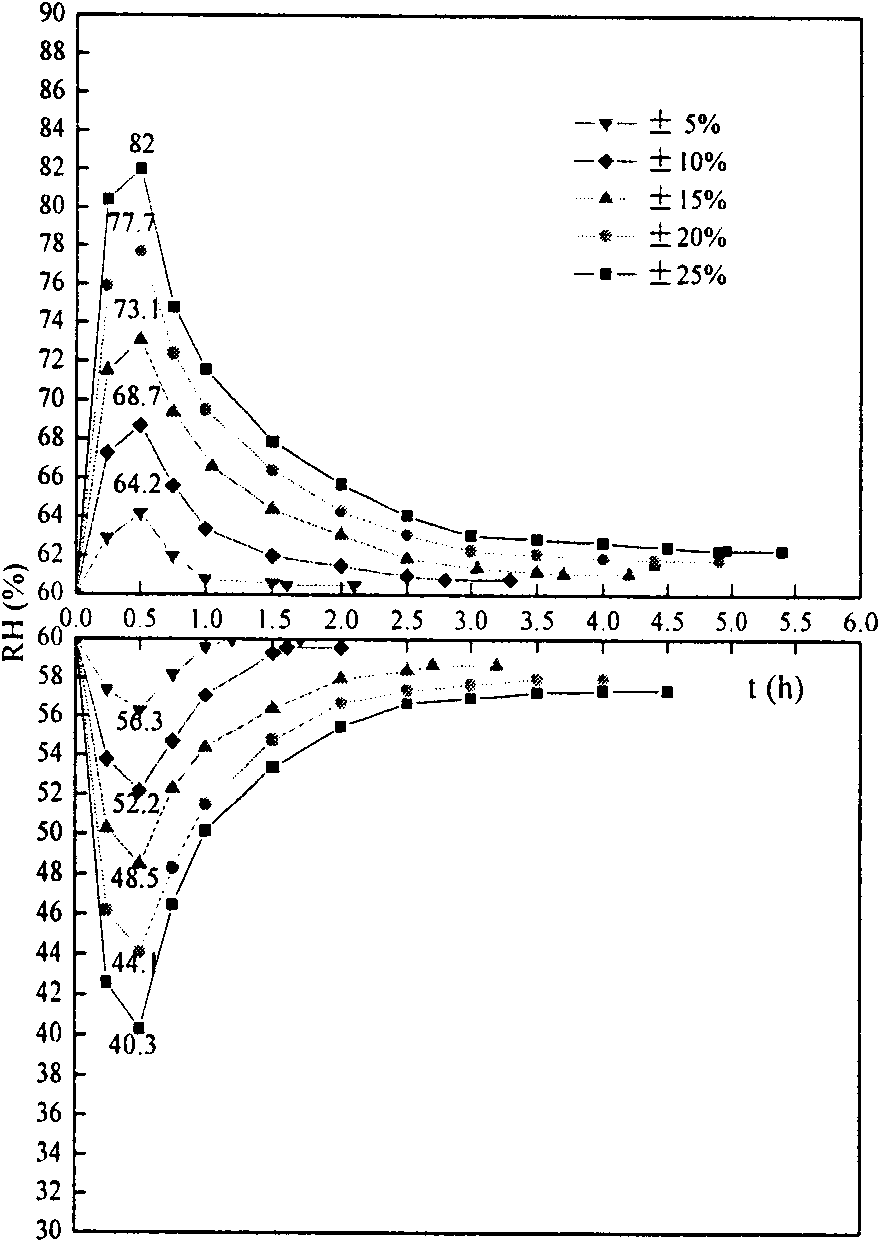

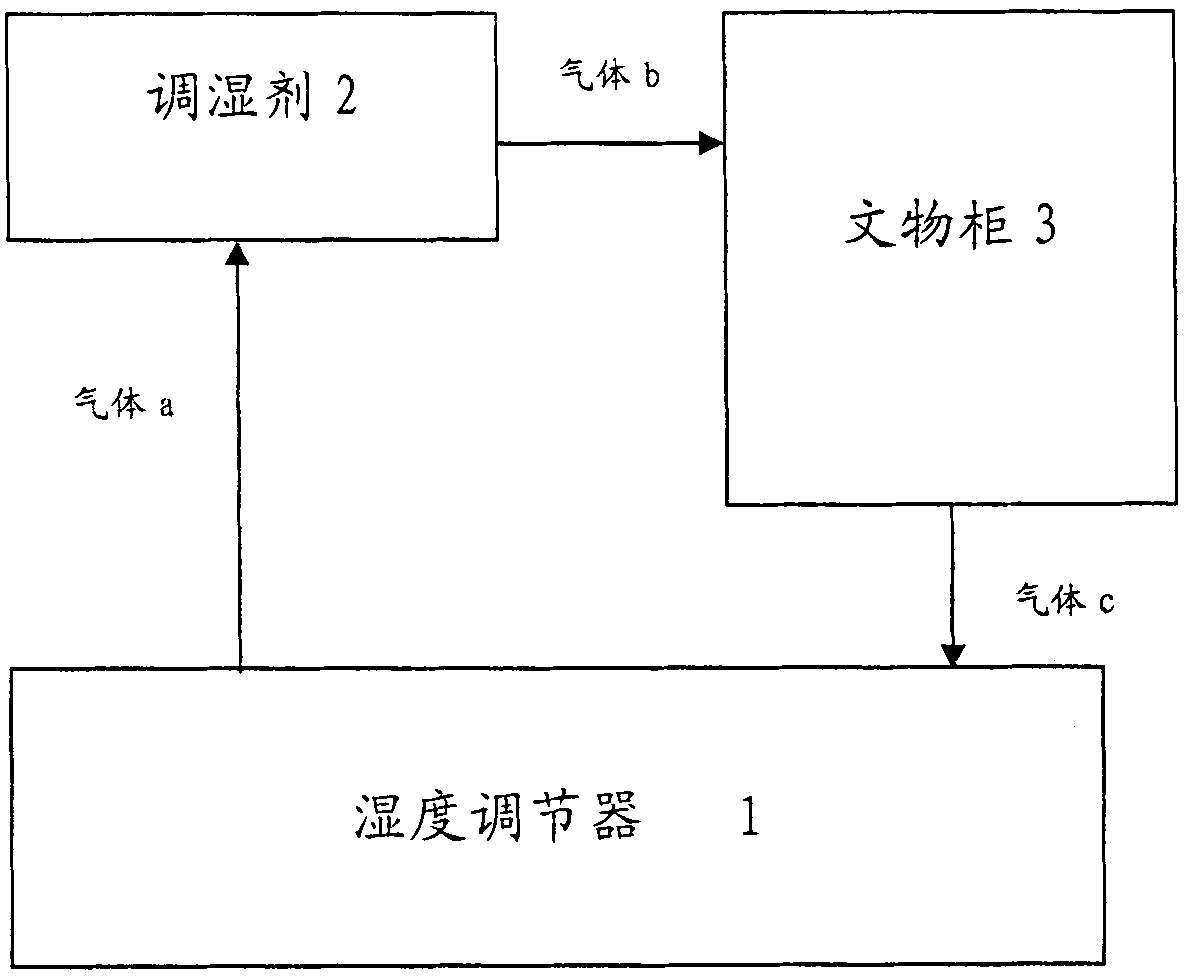

InactiveCN101950184AHigh humidity control rateIncrease moisture contentOther chemical processesHumidity controlHigh humidityEngineering

The invention discloses an alternate humidity control method for an energy-saving cultural relic cabinet. A humidity adjuster (1) is turned on by operating personnel when the operating personnel go to work in the morning and turned off when the operating personnel are off duty in the afternoon; the humidity of the cultural relic cabinet (3) is adjusted and controlled by the humidity adjuster (1) after the humidity adjuster (1) is turned on; and the humidity of the cultural relic cabinet (3) is adjusted and controlled by a humidity controlling agent (2) after the humidity adjuster (1) is turned off. Compared with the prior art, the method has the following advantages that: 1) by adopting the alternate humidity control method, the humidity in the cultural relic cabinet can still be adjusted and controlled within a set range after the humidity adjuster is turned off; 2) the humidity controlling agent is automatically regenerated when the humidity adjuster works, so that the additional trouble of manual regeneration treatment is saved; 3) the humidity controlling agent has higher humidity adjusting rate and higher humidity content compared with the conventional product; and 4) the energy consumption is greatly reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Anti-oil collagen cashmere composite fabric and production method thereof

InactiveCN106757442AMitigating the problem of year-on-year declineAvoid damageFilament/thread formingUltrasonic/sonic fibre treatmentPeppermintsLow temperature plasma

The invention discloses an anti-oil collagen cashmere composite fabric which is prepared from the following raw materials in parts by weight: 41 to 44 parts of cashmere fiber, 21 to 22 parts of silk fiber, 10 to 12 parts of glass fiber, 0.5 to 0. 7 part of sodium alginate, 8.8 to 8.9 parts of pure collagen powder, 2.8 to 2.9 parts of ethylene glycol diglycidyl ether, 6 to 8 parts of ginkgo biloba leaves, 0.1 to 0.2 part of peppermint oil, 2. 5 to 2.9 parts of nano zeolite powder, 1 to 2 parts of ethyl orthosilicate, 1.4 to 1.8 parts of dimethyldiethoxysilane, 184 to 188 parts of allyl-3-methimidazole chloride, and an appropriate amount of water. The oxygen low temperature plasma is used for pretreatment, ethylene glycol diglycidyl ether is used as a crosslinking agent to graft the modified collagen to the surface of a cashmere composite fiber, and the obtained cashmere composite fabric is durable and resists oil, not only has a good warmth property, but also has relatively high practicality.

Owner:ANHUI TIANWEI CASHMERE PROD

Hydrophilic super-cotton-like polyester fiber fabric

InactiveCN110241501AEfficient water absorption capacityImprove moisture absorption and release performanceWoven fabricsLiquid/gas/vapor textile treatmentWoolChemistry

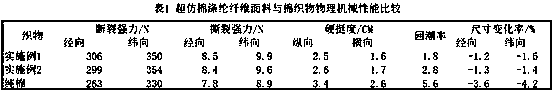

The invention discloses a hydrophilic super-cotton-like polyester fiber fabric. A gray fabric and a preparation method are involved. The gray fabric is woven from warp and weft by taking a plain weave or a twill weave as the fabric structure, the warp is prepared by blending hydrophilic polyester filament yarns and silk fibers, and the weft is prepared by blending odor-removing polyester filament yarns and chitosan fibers. According to the hydrophilic super-cotton-like polyester fiber fabric, wool powder is fused with FDY filament yarns, in the fusion process, liquid paraffin is utilized, the high-porosity surface structure wool-powder-containing hydrophilic polyester filament yarns and the high-porosity surface structure wool-powder-containing odor-removing polyester filament yarns are finally formed, then, the chitosan fibers and bamboo carbon fibers are adopted for separate blending, and the gray fabric is finally formed; due to the fact that the wool powder has high moisture absorption and releasing performance, and the hydrophilic polyester filament yarns and the odor-removing polyester filament yarns are high in porosity, the fabric prepared from a super-cotton-like material has efficient water absorption and moisture absorption capacities.

Owner:安徽翰林纺织有限公司

Cotton wood hemp bamboo composite cellulose pulp and mfg. process thereof

InactiveCN100355956CShinyGood colorConjugated cellulose/protein artificial filamentsSpinning solutions preparationPulp and paper industryCellulose pulp

Owner:YIBIN GRACE

After finishing method for sericin of cashmere product

Owner:苏州盛泽科技创业园发展有限公司

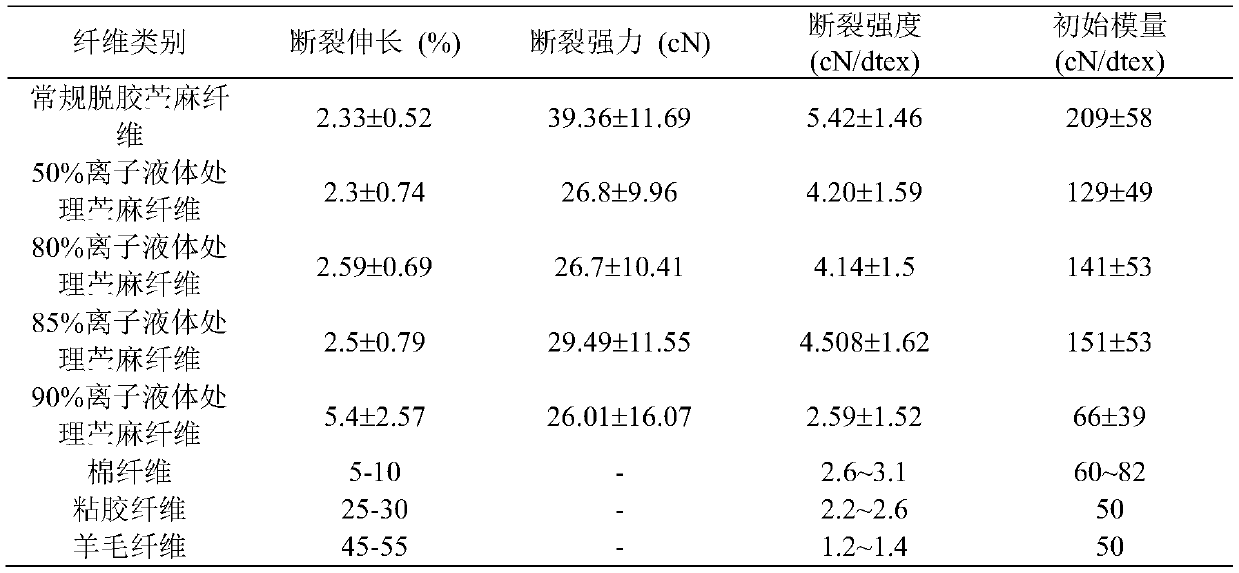

Ramie fiber softening method

ActiveCN111379162AReduce crystallinityLow modulusPhysical treatmentGrip property fibresPolymer scienceFiber Chemistry

The invention relates to the field of textile natural fibers, and provides a ramie fiber softening method comprising the following step (1) of immersing ramie fibers into a sodium hydroxide solution for swelling treatment; the step (2) of taking out the swelled ramie fibers, and placing the ramie fibers into water; gradually adding acidic solutions till pH is neutral, and washing the ramie fiberswith purified water; the step (3) of freezing and drying the washed ramie fibers, so that gaps of the ramie fibers are reserved; the step (4) of immersing the frozen and dried ramie fibers into ionicliquid with a certain concentration for ultrasonic treatment; the step (5) washing and drying the treated ramie fibers to obtain softened ramie fibers. According to the ramie fiber softening method, the crystallinity and modulus of the ramie fibers can be reduced obviously; since lots of gaps are increased in the ramie fibers, the moisture absorption and release properties of the fibers are improved; and meanwhile, by this way, the chemical composition of the fibers is not damaged, and the antibacterial component of the fibers can be reserved, so that the antibacterial activity of the fibers is reserved.

Owner:QINGDAO UNIV

Preparation method of spherical composite humidity-controlling material

InactiveCN102964763BIncrease wet capacityImprove humidity control performanceAluminium chlorideHalloysite

The invention relates to a preparation method of a spherical composite humidity-controlling material, which comprises the following steps of: a. activating halloysite for 2-3 hours to obtain activated halloysite; b. adding polyacrylic acid into a sodium hydroxide solution obtained by mixing sodium hydroxide with distilled water for neutralization, respectively adding konjac glucomannan, the activated halloysite, potassium peroxodisulfate, N, N'-methylene bisacrylamide and a aluminum chloride solution obtained by mixing aluminum chloride and water into a reactor filled with the neutralized solution, and stirring for reaction; c. adding sodium bicarbonate into the reactor to generate aluminum hydroxide and carbon dioxide, carrying out primary foaming, and stirring for reaction to obtain a synthetic product; d. drying the synthetic product at 80 DEG C and shearing the block synthetic product into small cubic pieces; and e. heating at the temperature of 150 DEG C to decompose aluminium hydroxide and evaporate water, carrying out secondary foaming and drying to obtain the spherical composite humidity-controlling material. The spherical composite humidity-controlling material is simple and convenient to prepare, low in cost, good in effect, environment-friendly and free from pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Absorb-discharge humid filter and humidifying apparatus

ActiveCN1808004BImprove moisture absorption and release performanceLighting and heating apparatusAir humidification systemsWater useProcess engineering

Owner:PANASONIC CORP

A kind of preparation method of composite humidity control material

The invention discloses a preparation method of a compound humidifying material, which comprises the following steps of: a, adding 5 parts by mass of sodium chloride and 10 parts by mass of potassium carbonate in 35 parts by mass of water, uniformly stirring to obtain a mixed solution, then adding 15 parts by mass of sodium polyacrylate resin in the mixed solution for later use; b, preparing 5 parts by mass of sepiolite roasted at a temperature of 250-300 DEG C for 2-2.5h, 6 parts by mass of polyvinyl alcohol and 2 parts by mass of urea into a solution, adding the solution into the mixture obtained in the step a, mixing and stirring; c, adding 3 parts by mass of sodium chloride and 66.7 parts by mass of potassium carbonate in 200 parts by mass of water, stirring to obtain a mixed solution; and d, adding the mixture obtained in the step b into the mixed solution obtained in the step c, mixing and uniformly stirring, then drying at 140-150 DEG C in an oven to prepare the humidifying material. The humidifying material has the advantages of low cost, high response speed, good effect and simpleness in process, is convenient to use and is harmless and non-toxic.

Owner:ZHEJIANG SCI-TECH UNIV

Composite cellulose viscose filament using composite cellulose pulp as raw material made from cotton, wood, hemp and bamboo and its preparation method

ActiveCN1904151BBroaden sources of raw materialsImprove moisture absorption and release performanceWet spinning methodsSpinning solutions preparationFiltrationCellulose pulp

Owner:YIBIN GRACE

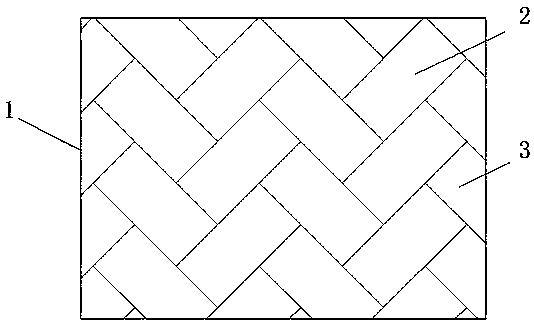

A kind of preparation method of sodium polyacrylate-halloysite-konjac glucomannan composite humidity-conditioning agent

InactiveCN102964764BImprove antibacterial propertiesWide range of antibacterialHalloysitePotassium persulfate

The invention relates to a method for preparing a sodium polyacrylate-halloysite-konjac glucomannan composite humidity conditioning agent. The method comprises the following steps of: (a) activating halloysite at the temperature of 450 DEG C; (b) weighing polyacrylic acid, adding the weighed polyacrylic acid into sodium hydroxide liquid, prepared from sodium hydroxide and distilled water, to neutralize, weighing konjac glucomannan, activated halloysite, nano silver-loaded antimicrobial powder, potassium persulfate, N,N'-methylene-bis-acrylamide, and aluminum chloride liquid, prepared from aluminum chloride and water, respectively adding the weighed konjac glucomannan, activated halloysite, nano silver-loaded antimicrobial powder, potassium persulfate, N,N'-methylene-bis-acrylamide and aluminum chloride liquid into a reactor containing neutralized liquid, and carrying out reaction for 1-2 hours while stirring; (c) cooling a polymer obtained in the step (b) to room temperature, then drying the polymer for 2-3 hours at the temperature of 150 DEG C, and carrying out secondary foaming and pore forming; and (d) crushing a dried humidity conditioning material for 2-3 minutes by using a crusher, thereby obtaining a powdered humidity conditioning agent. According to the method for preparing the sodium polyacrylate-halloysite-konjac glucomannan composite humidity conditioning agent, the humidity conditioning agent has the advantages of rapid humidity conditioning response and moisture absorption and desorption rate, large moisture content / capacity, good relative humidity stability, simplicity and convenience in preparation, low cost, good effect, environmental friendliness, no pollution, no toxicity and harmlessness.

Owner:ZHEJIANG SCI-TECH UNIV

Collagen and cashmere composite fabric with anti-bacterial and radiation-proof functions and preparation method of fabric

InactiveCN106521954AMitigating the problem of year-on-year declineImprove hydrophilicityConjugated cellulose/protein artificial filamentsUltrasonic/sonic fibre treatmentFiberSilanes

The invention discloses collagen and cashmere composite fabric with anti-bacterial and radiation-proof functions. The collagen and cashmere composite fabric with anti-bacterial and radiation-proof functions is prepared from raw materials in parts by weight as follows: 43-46 parts of cashmere fibers, 18-20 parts of far infrared ceramic fibers, 14-17 parts of milk protein fibers, 8.6-9.3 parts of pure collagen powder, 2.6-3.3 parts of ethylene glycol diglycidyl ether, 1-2 parts of white oil, 5-7 parts of tea leaf residues, 0.2-0.4 parts of anhydrous sodium pyrophosphate, 2.4-2.7 parts of nano barium sulfate, 1.4-1.7 parts of chloromethyl pivalate, 1.2-1.5 parts of a silane coupling agent KH560, 192-197 parts of 1-allyl-3-methylimidazolium chloride and a proper amount of water. Oxygen low-temperature plasma is adopted for pretreatment, modified collagen is grafted on surfaces of cashmere composite fibers with ethylene glycol diglycidyl ether as a crosslinking agent, and the prepared cashmere composite fabric has better anti-bacterial and radiation-proof functions and dyeing performance.

Owner:ANHUI TIANWEI CASHMERE PROD

Method for manufacturing breathable moisture absorption modified polyester fibers

ActiveCN102400247BImprove moisture absorption and release performanceShort response timeMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPotassium persulfate

The invention discloses a method for manufacturing breathable moisture absorption modified polyester fibers. The method comprises the following steps of: A) adding sepiolite into a 2 mass percent hydrochloric acid solution in a mass ratio of 1: (6-10), stirring for 0.5 to 1.5 hours, dehydrating and drying, and thus obtaining activated sepiolite; B) adding the activated sepiolite into a 4 mass percent cetyl trimethyl ammonium bromide solution in a mass ratio of 1: (4-6), stirring for 2 to 3 hours, drying, and thus obtaining organic sepiolite; C) taking 0.1 to 0.5 mass parts of glycol diglycidyl diethyl ether, 0.5 to 1.5 mass parts of sodium carboxymethylcellulose, 4 to 6 mass parts of sodium polyacrylate, 0.05 to 0.15 mass part of potassium persulfate, 1 to 3 mass parts of organic sepiolite and 6 to 10 mass parts of water, performing stirring reaction for 1 to 3 hours at the temperature of between 70 and 90 DEG C, drying, grinding, and thus obtaining a modified functional material, the grain diameter of which is not more than 15 microns; and D) adding 5 to 15 parts of functional material into 85 to 95 parts of polyester melt, uniformly mixing the functional material into the polyester melt with high-speed stirring, and spinning by using a spinneret plate with 'cross' special-shaped holes.

Owner:扬州富威尔复合材料有限公司

Preparation method of diatomite-based building humidifying material

InactiveCN111003975AImprove the ability of automatic moisture absorption and releaseImprove the ability to absorb and release moistureCeramicwareEmulsionUltrasonic oscillation

The invention provides a preparation method of a diatomite-based building humidifying material, and relates to the field of humidifying materials, and the method comprises the following steps: refining diatomite; preparing inorganic salt modified diatomite; mixing the inorganic salt modified diatomite with bentonite and straw fibers, then adding the mixture into emulsion, carrying out ultrasonic oscillation for 5-15 minutes, uniformly dispersing microcrystalline wax into the emulsion, heating to 40-50 minutes, filtering out, and carrying out wet pressing molding to obtain a blank; transferringthe blank into a hydrothermal reaction kettle, performing hydrothermal treatment for 5 to 10 hours at a temperature of 120 to 150 DEG C and a saturated vapor pressure of 0.5 to 1.2 MPa, and aging for10 to 20 days.The diatomite-based building humidifying material has the advantages that the mechanical strength is excellent, in addition, the moisture absorption and desorption performance is good,the moisture absorption rate reaches 23.2 percent, the moisture desorption rate reaches 19.1 percent, and the function of adjusting the air humidity is realized.

Owner:安徽领珂数据科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com