Preparation method of diatom-based hydrated calcium silicate powder moisture regulating material

A technology of hydrated calcium silicate powder and humidity control material, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of inability to achieve reversible adsorption/desorption of a large amount of water vapor, difficulty in water molecule migration/diffusion, mesoporous , low content of macropores, etc., to achieve the effect of strong moisture absorption and release ability of the product, cheap raw materials, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, Jilin Changbai produces diatomite, SiO 2 The content is 61.38% by mass percentage, and the specific surface area is 65m 2 / g. Using diatomite as raw material, the specific process and technical parameters of the diatom-based calcium silicate hydrate powder humidity-conditioning material are:

[0030] (1) Mix diatomaceous earth and calcium hydroxide according to the calcium-silicon molar ratio of 0.45, add mixing water with a dry weight of 20% and continue mixing until completely uniform;

[0031] (2) The reaction mixture is subjected to a hydrothermal reaction for 4 hours in a saturated water vapor environment at 200°C;

[0032] (3) The obtained sample is moderately ground after drying to obtain a diatom-based calcium silicate hydrate powder humidity control material.

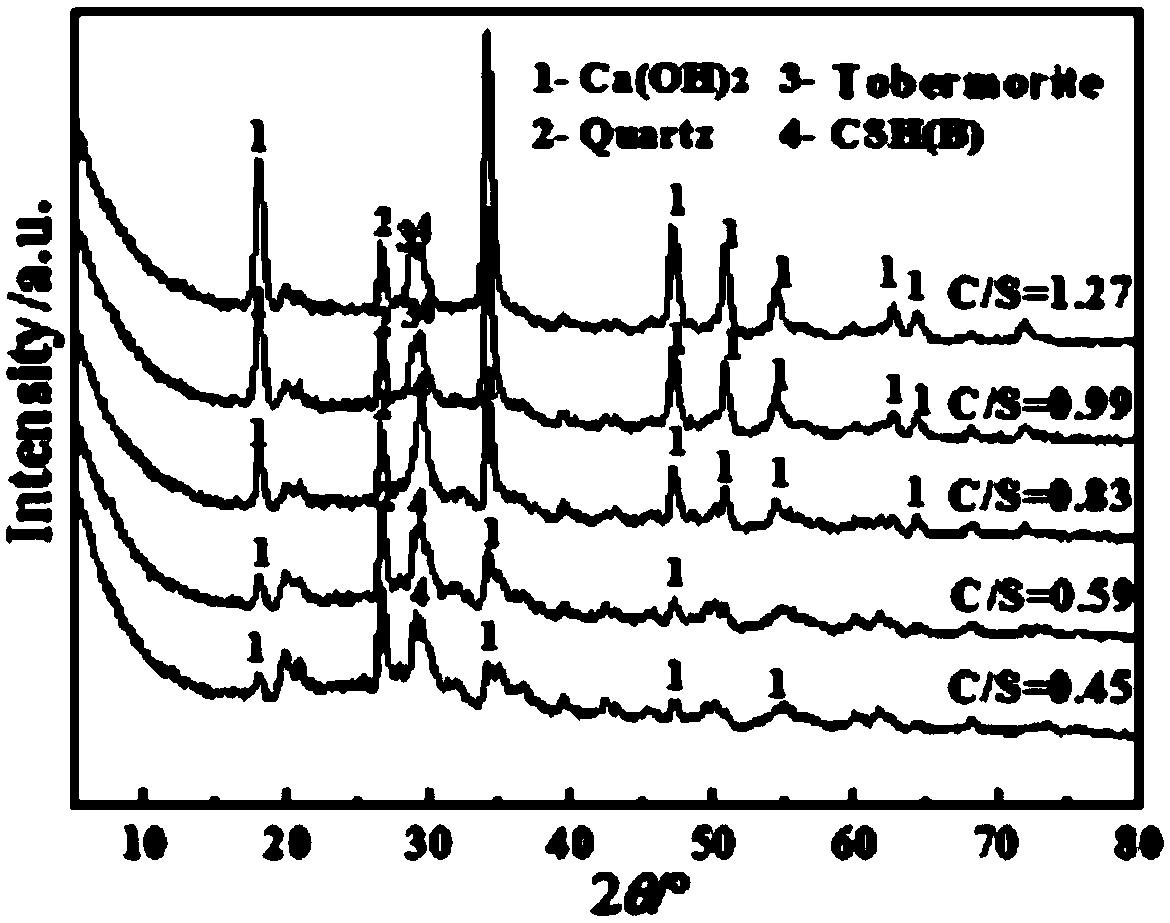

[0033] The X-ray diffraction (XRD) results of the calcium silicate hydrate powder obtained by the hydrothermal reaction are shown in figure 1 , analysis showed that the reaction prod...

Embodiment 2

[0036] In this example, the diatom-based calcium silicate hydrate powder humidity-conditioning material was prepared according to the steps of Example 1, the difference is that calcium oxide is used as the calcium raw material in step (1), and the calcium-silicon molar ratio is adjusted to 1.0; other operating steps and conditions are the same. The X-ray diffraction (XRD) results of the calcium silicate hydrate powder obtained by the hydrothermal reaction are shown in figure 1, the analysis showed that the reaction product in the powder was mainly semi-crystalline calcium silicate hydrate CSH (B), but the diffraction peak of calcium hydroxide remained, indicating that the calcium oxide in the raw material was excessive. The humidity control performance test shows that the 24h moisture absorption of the powder in an environment with a relative humidity of 75% after drying (105°C) reaches 6.56% (mass percentage), and then the 24h moisture release in an environment with a relativ...

Embodiment 3

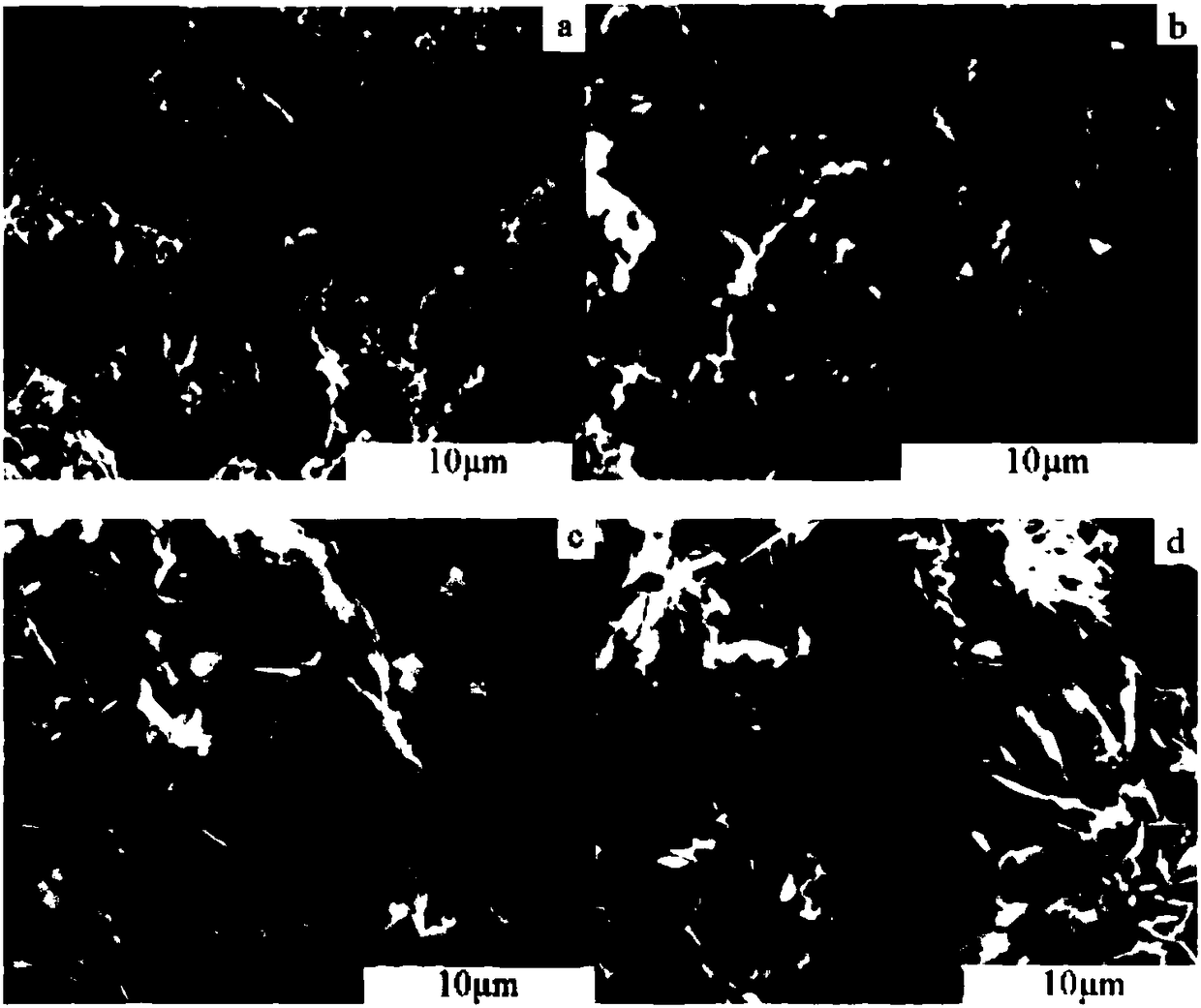

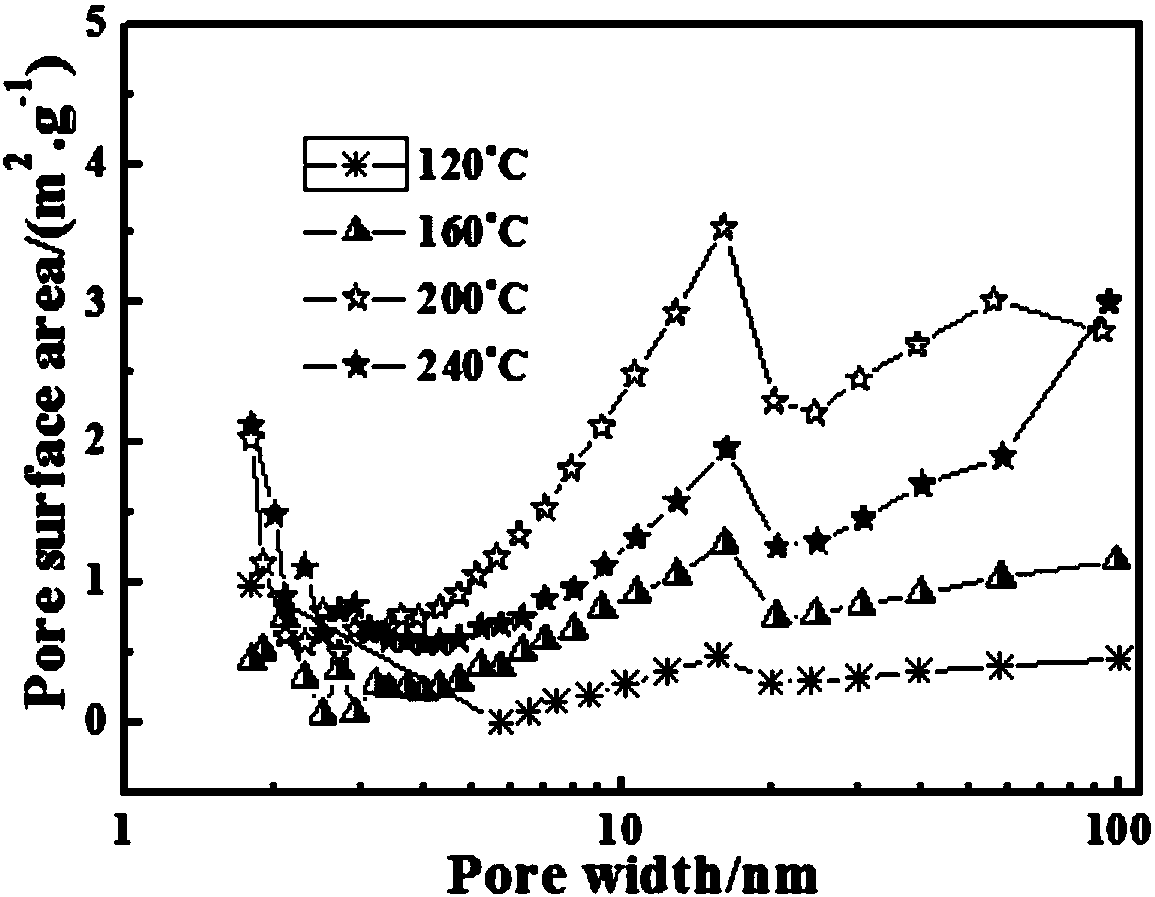

[0038] In this example, the diatom-based calcium silicate hydrate powder humidity-conditioning material was prepared according to the steps of Example 1, the difference being that the hydrothermal reaction conditions in step (2) were adjusted to 120°C and 4h; other operating steps and Same conditions. The scanning electron microscope (SEM) microscopic morphology of calcium silicate hydrate powder obtained by hydrothermal reaction is shown in figure 2 (a), indicating that the hydration product is calcium silicate hydrate with poor crystallinity, and the reaction is not complete. Nitrogen adsorption experiments show that the pore content of the calcium silicate hydrate powder in the range of 2-50nm pore diameter reaches 0.012cm 3 / g, the humidity control performance test shows that the moisture absorption of the powder after drying (105°C) in an environment with a relative humidity of 75% reaches 5.31% (mass percentage) for 24 hours, and then it is transferred to an environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com