Absorb-discharge humid filter and humidifying apparatus

A technology for absorbing and releasing moisture and humidifying device, which is applied in the field of humidifying device, can solve the problems such as the decrease of absorbing and releasing performance, hinder the capillary tube, etc., and achieve the effect of improving the performance of absorbing and releasing moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

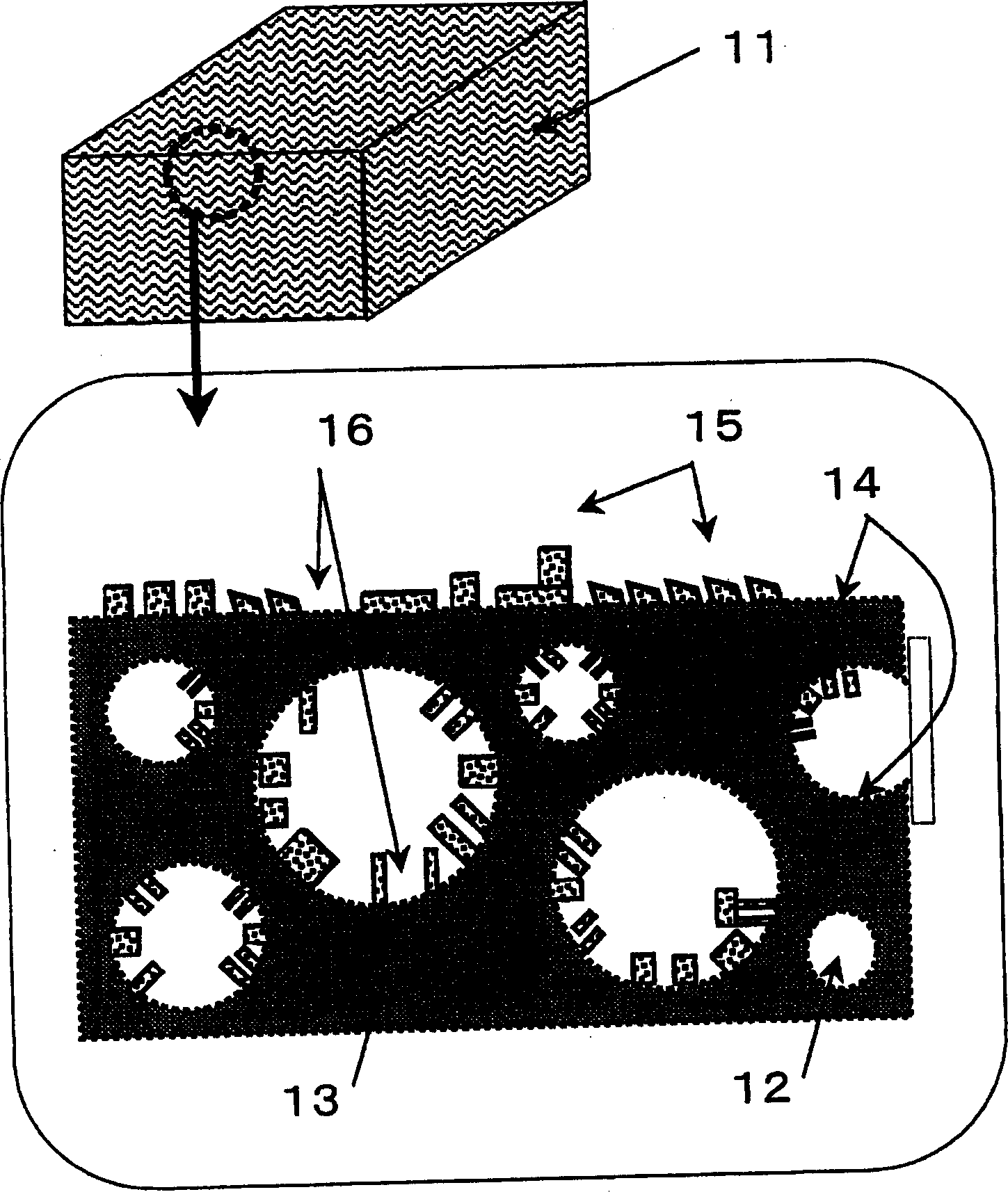

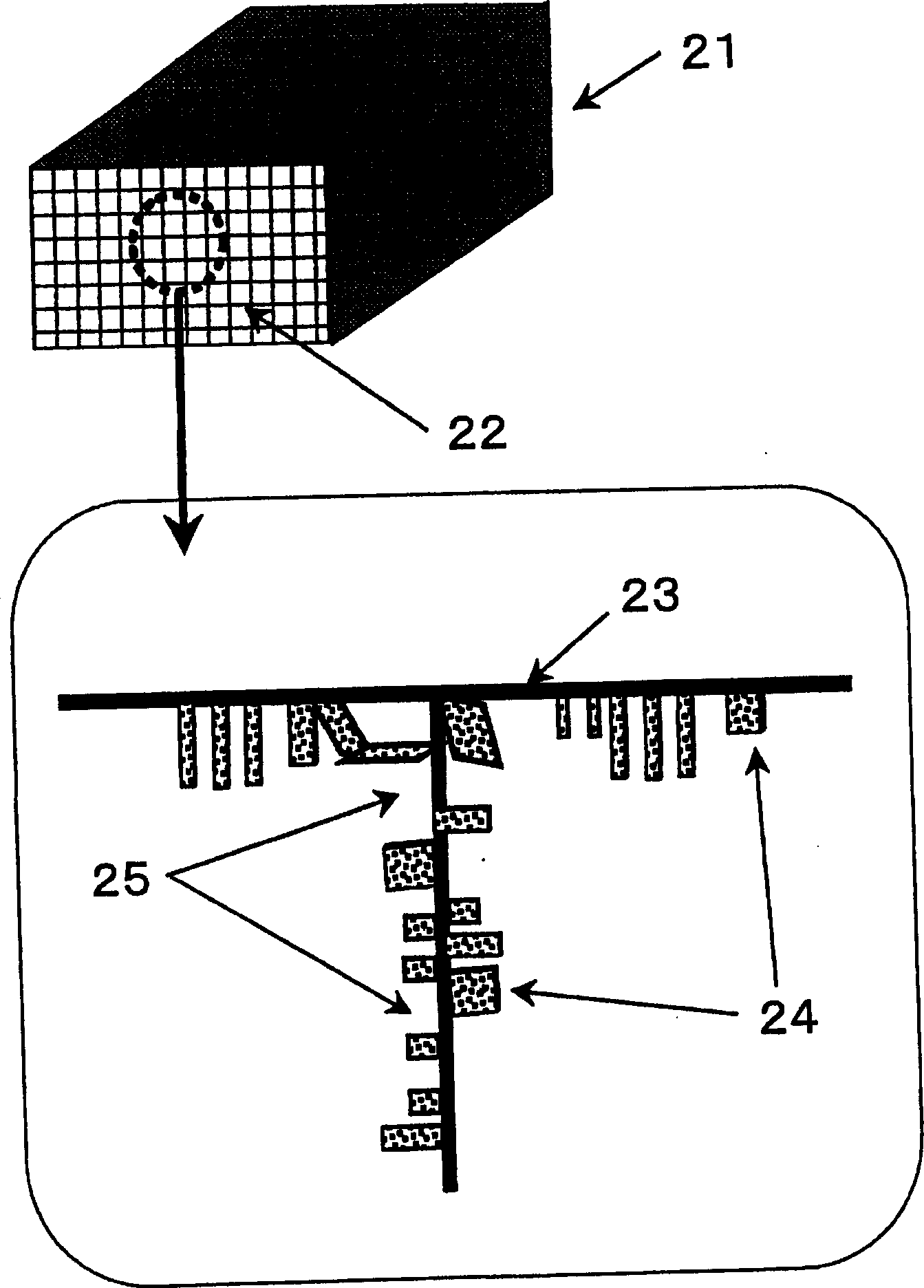

[0055] (Embodiment 1) Production of suction and release moisture filter

[0056] Ethanol and 1N hydrochloric acid were added to tetraethoxysilane for hydrolysis to prepare a binder solution. Mix talc and 1,1'-hexylidene bis[5-(4-chlorophenyl)biguanide] dihydrochloride as an antibacterial agent into the adhesive solution, and Albiline as an antifungal agent, and stir with a ball mill Dispersion was carried out for 5 hours to prepare a slurry.

[0057] The obtained slurry was charged into a sprayer for coating, and sprayed on both the front and back sides of the polyurethane foam and ceramic honeycomb substrate. Then, it was dried at about 100° C. for about 20 minutes to obtain a hygroscopic filter.

[0058] The foaming polyurethane with foaming density of 6 holes / 25mm, 6-10 holes / 25mm, 11-17 holes / 25mm, and 17-23 holes / 25mm was used to make hygroscopic filters. If the foaming density is 17-23 holes / 25mm or more, the pore interval of the foamed polyurethane is too small, and ...

Embodiment 2

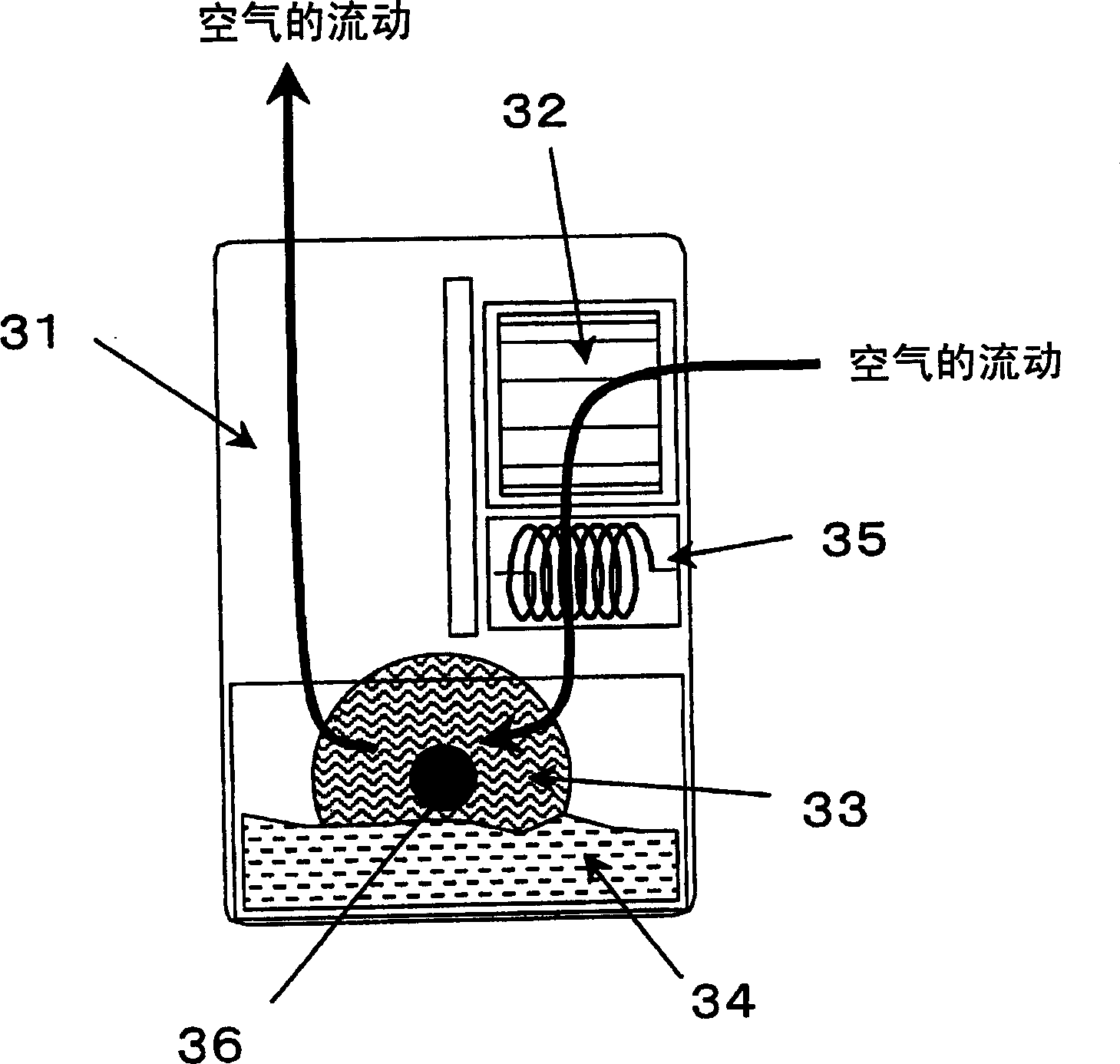

[0060] (Embodiment 2) Humidifier

[0061] image 3 and Figure 4 Shown is a simplified cross-sectional view from the front and side of the humidifier. The humidifier 31 includes an air blower 32 as an air blower, a hygroscopic filter 33 , and a water tank 34 . An air heating unit 35 serving as an air heating unit is disposed between the air blowing unit 32 and the moisture absorbing and desorbing filter 33 . The cylindrical hygroscopic filter rotates around the shaft 36 . The dry air sucked into the humidifier 31 by the blower unit 32 is heated to about 50° C. by the air heating unit 35 , and passes through the moisture absorbing and desorbing filter. At this time, the hygroscopic filter 33 is in a wet state by receiving water from the water tank 34, so the water is vaporized, and humidified air is supplied to the downstream side.

[0062] The moisture absorbing and desorbing filter produced in Example 1 was placed in the humidifier, and the device was operated to measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com