Cellulose fiber blended fabric

A cellulose fiber and fabric technology is applied in the field of cellulose fibers mixed with fabrics to achieve the effects of improving the use effect, improving the moisture absorption and releasing properties, and the comfortable wearing feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

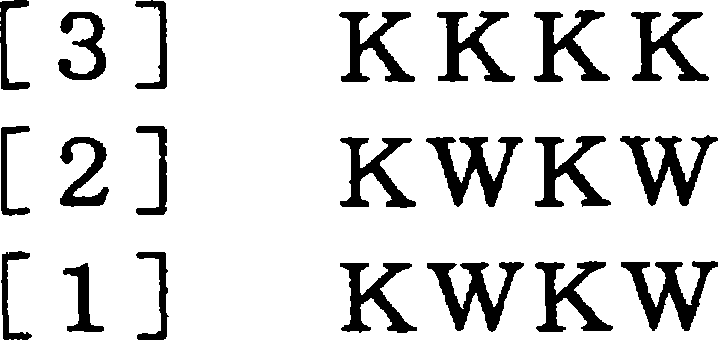

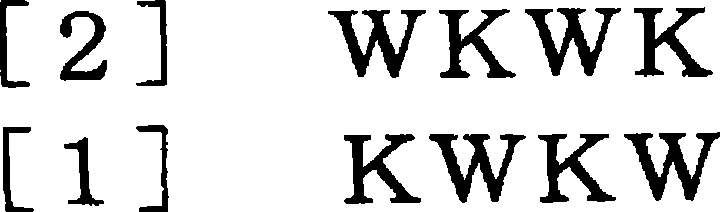

[0167] A circular knitting machine with a gauge (gauge) 28 is used to weave the circular rib structure. At this time, the ordinary fibers and the cellulose fibers are arranged and woven alternately. In this weaving, 84dt / 36f polyester fiber 84dt / 45f copper ammonia fiber was used as the cellulose fiber and the 84dt / 45f cupro fiber was used as the normal fiber. At this time, the cupro fibers used are ordinary cupro fibers that have not been subjected to alkali treatment.

[0168] Put the woven gray fabric into a liquid flow dyeing machine, refine it at 80°C for 20 minutes, drain it, and then treat it with alkali at 30°C for 20 minutes with a concentration of 60g / L of sodium hydroxide. Next, only the ester side was dyed at 130°C. Since the dyed knitted fabric becomes uneven, it was dried using a short-ring dryer, stretched with a pin tenter until the wrinkles of the knitted fabric can be removed, and set at 170° C. for 60 seconds. In addition, at the time of this dyeing, it dye...

Embodiment 2~8

[0171] Cellulosic fibers having different water-absorbing elongations were produced by changing the alkali treatment conditions and the types of cellulosic fibers in Example 1. Table 1 shows the results of evaluating the wearing comfort of the knitted fabric using this fiber.

Embodiment 9

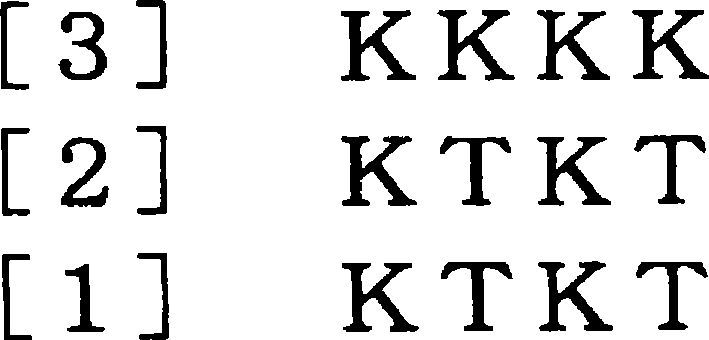

[0173] The raw polyester fiber 56dt / 24f of ordinary fiber as the warp, the raw polyester fiber 56dt / 24f of ordinary fiber as the weft, and the 67dt / 24f of rayon fiber are alternately beaten and weaved into 3 / 1 warp satin weave.

[0174]Put the woven gray fabric into a liquid flow dyeing machine, refine it at 80°C for 20 minutes, drain it, and then treat it with alkali at 50°C for 25 minutes with a concentration of 50g / L of sodium hydroxide. Next, only the ester side was dyed at 130°C. Since the dyed fabric became uneven, it was dried using a short-ring dryer, stretched with a pin tenter until the wrinkles of the knitted fabric could be removed, and set at 180° C. for 60 seconds. In addition, a water-absorbing agent is used for this finishing and setting.

[0175] The rayon fibers of the obtained fabric were drawn out, and the water absorption elongation was measured to be +9.3%.

[0176] In addition, the obtained fabric was subjected to a comfortable wearing test during exe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com