After finishing method for sericin of cashmere product

A post-finishing and cashmere technology, which is applied in fiber treatment, textiles, papermaking, animal fibers, etc. It can solve the problems of poor washability and rough hand feeling of textiles, and achieve good washability, good application prospects, and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

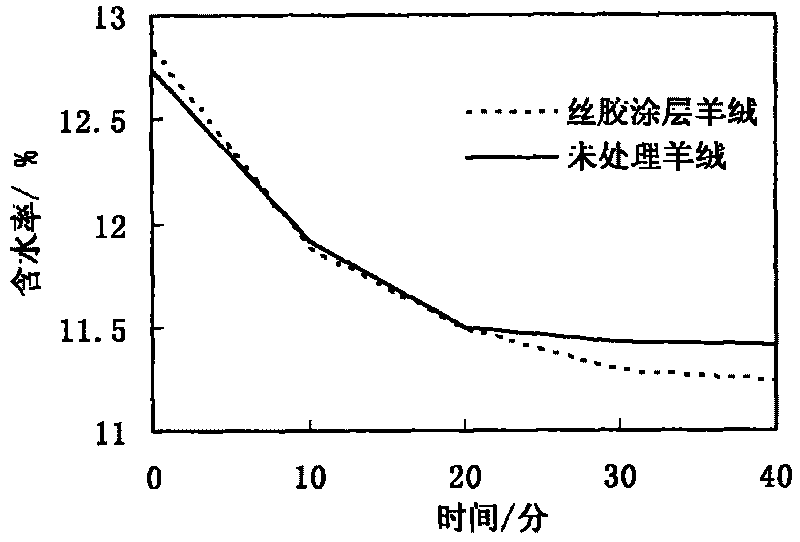

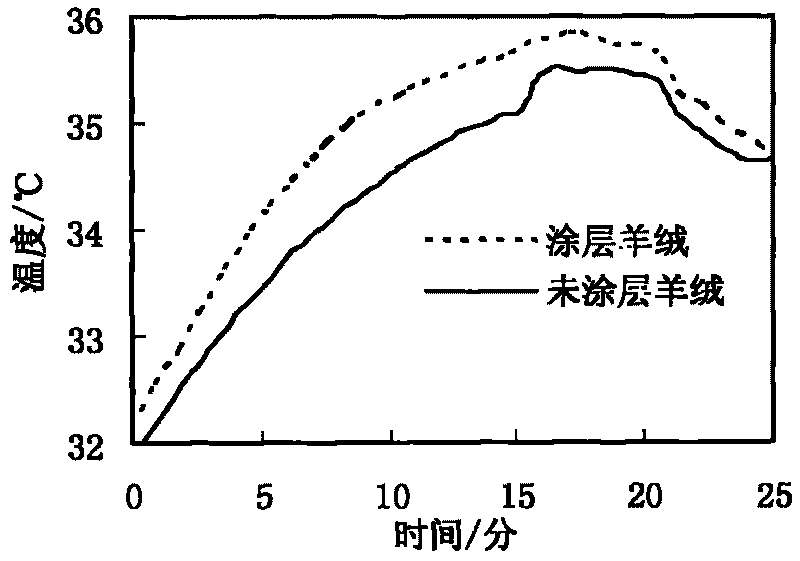

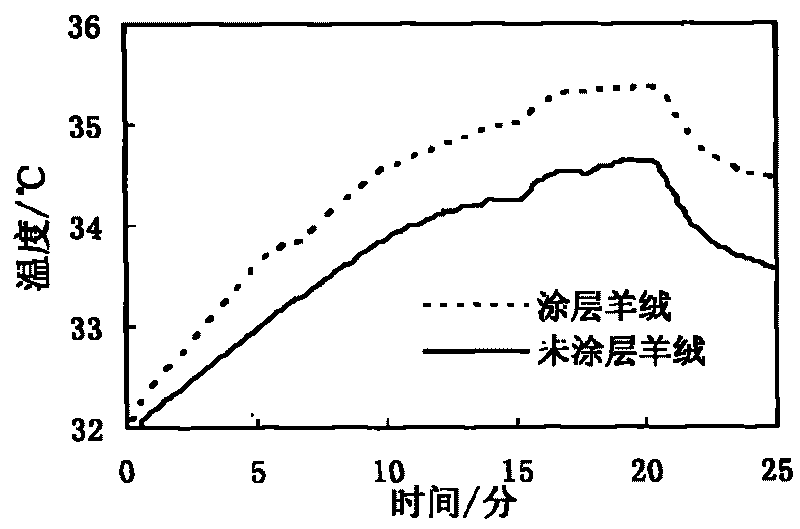

Image

Examples

Embodiment 1

[0030] A sericin finishing method for cashmere products, including the following steps:

[0031] (1) Preparation of crosslinking agent:

[0032] (a) Pre-emulsification: Add an emulsifier to an appropriate amount of deionized water, stir to dissolve, add the crosslinking monomer, acrylate monomer and N-methylolacrylamide dropwise while stirring within 2 hours to obtain a monomer Body emulsion; the emulsifier is Tween-80, the acrylic monomers include 45-60% ethyl acrylate, 20-35% butyl acrylate and 20-25% methacrylic acid by weight Methyl ester

[0033] (b) Polymerization: Add an initiator to an appropriate amount of deionized water, stir and raise the temperature to 75°C, and then add dropwise the monomer emulsion obtained in step (1). The reaction temperature is 75-85°C. After reacting for 1 hour, the monomer emulsion and the initiator The agent is added dropwise at intervals, and the addition is completed within 2 to 3 hours. The temperature is raised to 85°C and the reaction is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com