Hydrophilic super-cotton-like polyester fiber fabric

A polyester fiber and hydrophilic technology, applied in the field of clothing fabrics, can solve the problems of airtightness, cold and fever, skin irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

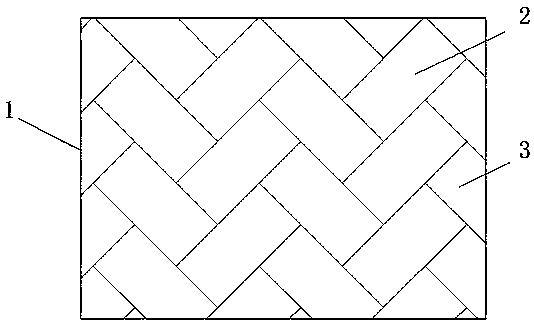

[0024] A hydrophilic super imitation cotton polyester fiber fabric, comprising a gray cloth 1, the gray cloth 1 is formed by weaving a warp thread 2 and a weft thread 3 with plain or twill weave as the fabric structure, and the warp thread 2 is made of hydrophilic polyester filament and silk fiber It is blended, the warp 2 has a denier of 22.2dtex, and the density is 316-334; the weft 3 is made of deodorizing polyester filament and chitin fiber, and the weft 3 is 21.5dtex, and the density is 292-310 root; hydrophilic polyester filament contains weight percent: 70-85% polyester FDY filament and 15-30% wool powder; the average particle size of wool powder is 20-30 μm, and the weight percentage of deodorizing polyester filament is: 60 -70% polyester FDY filament and 30-40% bamboo charcoal fiber; the section of polyester FDY filament is "ten" shape.

[0025] A kind of preparation method of hydrophilic super imitation cotton polyester fiber fabric comprises the following steps:

...

Embodiment 2

[0032] A hydrophilic super imitation cotton polyester fiber fabric, comprising a gray cloth 1, the gray cloth 1 is formed by weaving a warp thread 2 and a weft thread 3 with plain or twill weave as the fabric structure, and the warp thread 2 is made of hydrophilic polyester filament and silk fiber It is blended, the warp 2 has a denier of 21.3dtex, and the density is 310-320; the weft 3 is made of deodorant polyester filament and chitin fiber blended, and the weft 3 is 22dtex, and the density is 280-290 ; The weight percentage of hydrophilic polyester filament is: 65-80% polyester FDY filament and 20-35% wool powder; the average particle size of wool powder is 15-20 μm, and the weight percentage of deodorizing polyester filament is: 65- 75% polyester FDY filament and 25-35% bamboo charcoal fiber; the section of polyester FDY filament is "Y" shape.

[0033] A kind of preparation method of hydrophilic super imitation cotton polyester fiber fabric comprises the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com