Drying system for drying color changing film through hot air

A technology of hot air drying and drying system, applied in drying, drying machines, progressive drying machines, etc., can solve the problems of reduced drying effect of color changing film, uneven hot air blowing, low drying efficiency of color changing film, etc. Achieve the effect of improving service life, avoiding bulging and folding, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

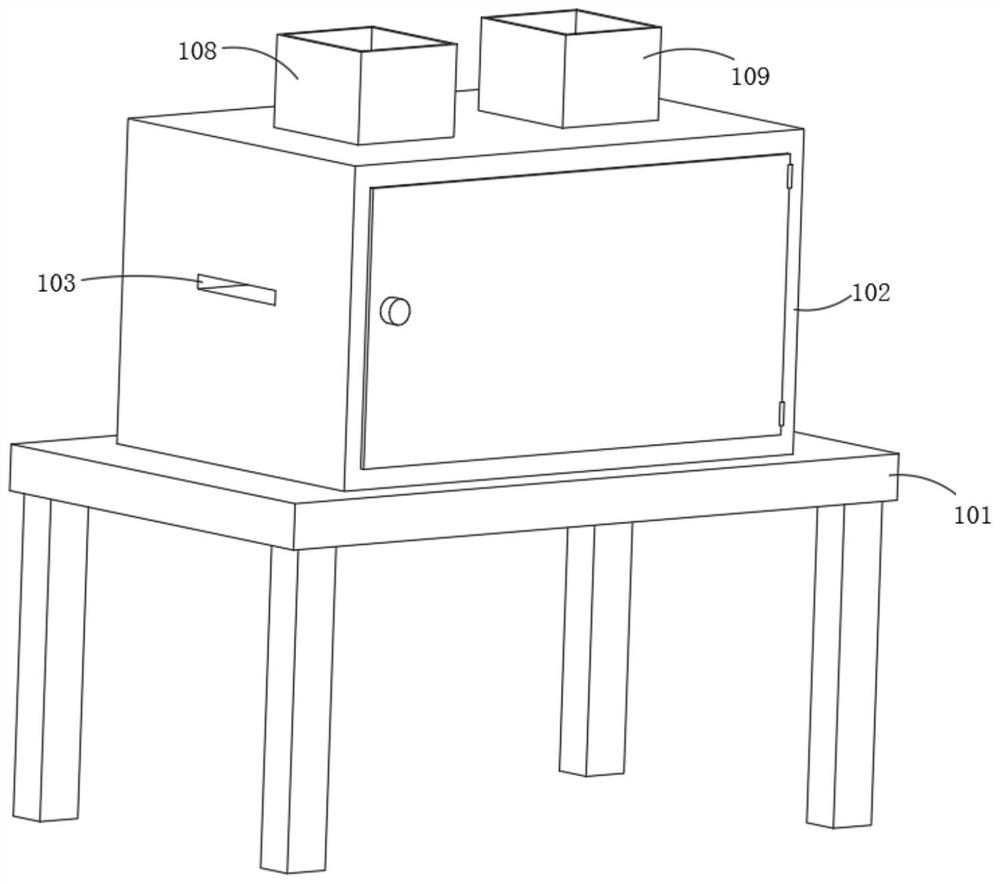

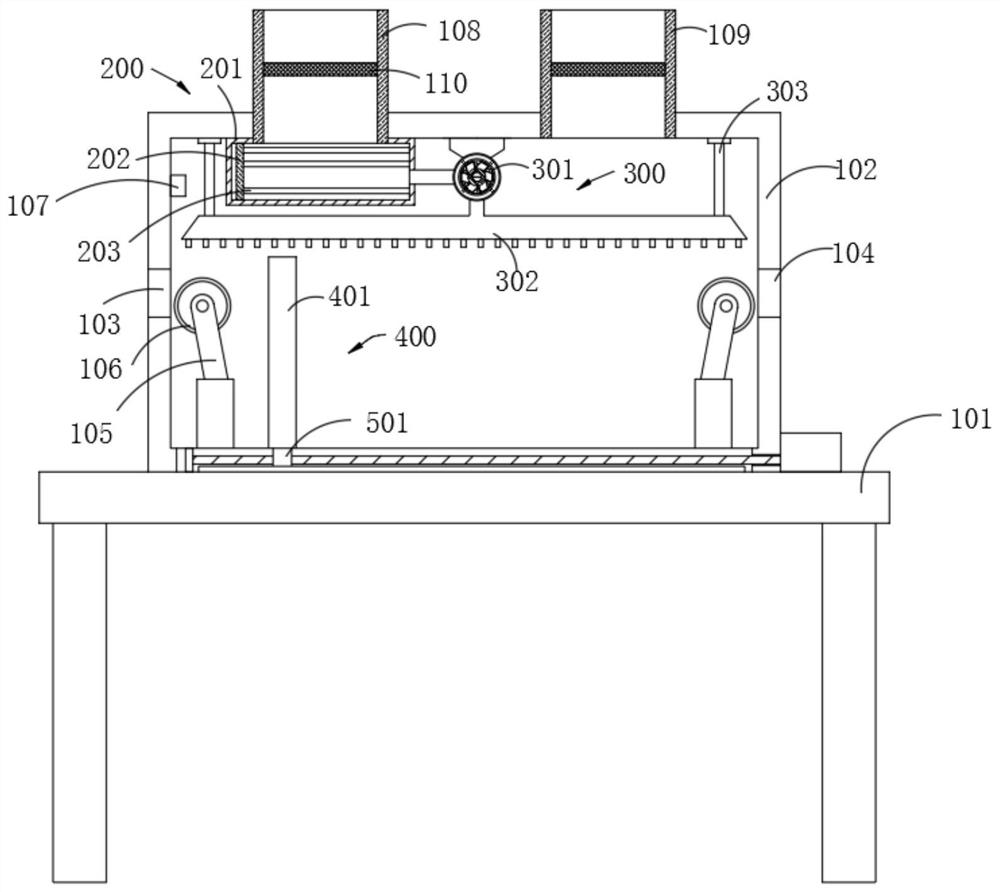

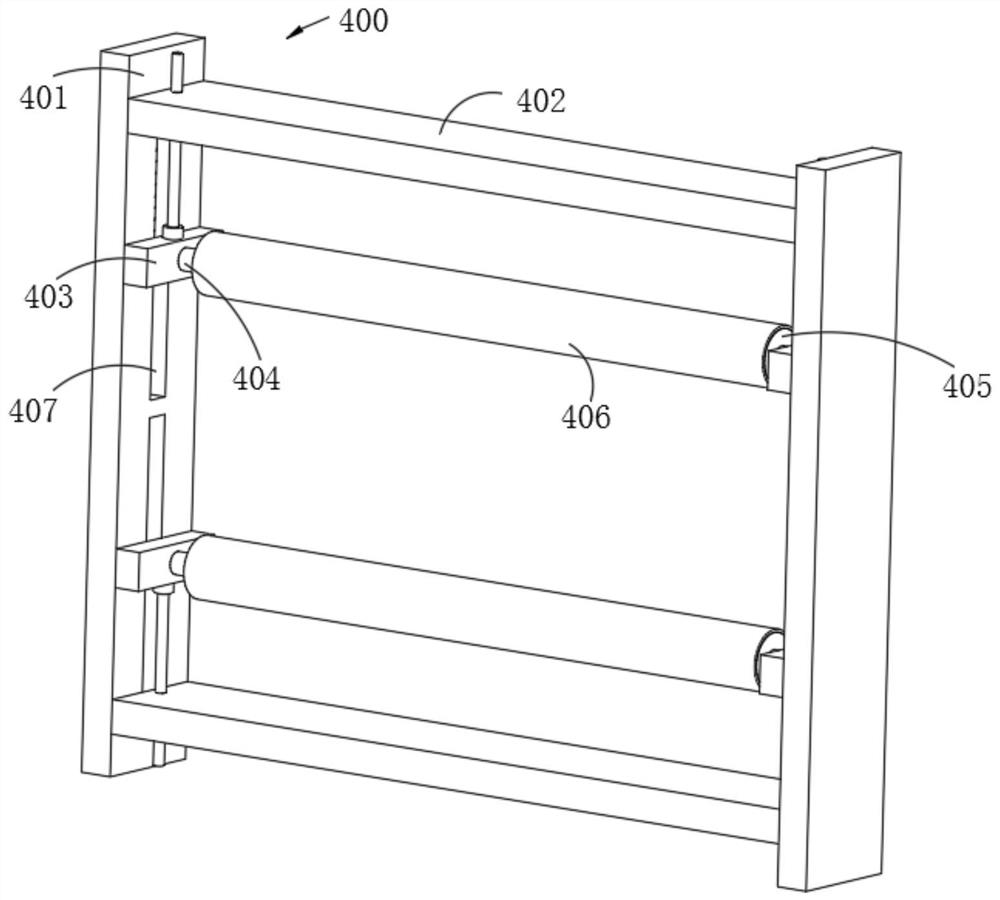

[0031] see Figure 1-6, the present invention provides a technical solution: a drying system for drying color-changing films with hot air, including a workbench 101, a drying box 102 is fixedly installed on the top of the workbench 101, and two side walls of the drying box 102 are respectively provided with The film inlet 103 and the film outlet 104, both sides of the bottom of the drying box 102 are fixed with brackets 105, and each bracket 105 is rotatably connected with a guide roller 106, and the color changing film roll that needs to be dried is introduced from the film inlet 103 , the color-changing film is pasted on two sets of guide rollers 106 to facilitate the drying of the color-changing film.

[0032] Guide rollers 106 are respectively arranged on one side of film inlet 103 and film outlet 104, and temperature and humidity sensor 107 is fixedly installed on the inner wall of drying box 102, and temperature and humidity sensor 107 monitors the temperature and humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com