A kind of preparation method of natural color bamboo fiber biochemical mechanical pulp

A biochemical and bamboo fiber technology, applied in the pulp beating method, pulp beating/refining method, non-woody plant/crop pulp, etc., can solve the problems of difficult to control cooking uniformity, unstable quality, etc., and achieve relief Raw material cost pressure, reduction of debris generation, effects of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

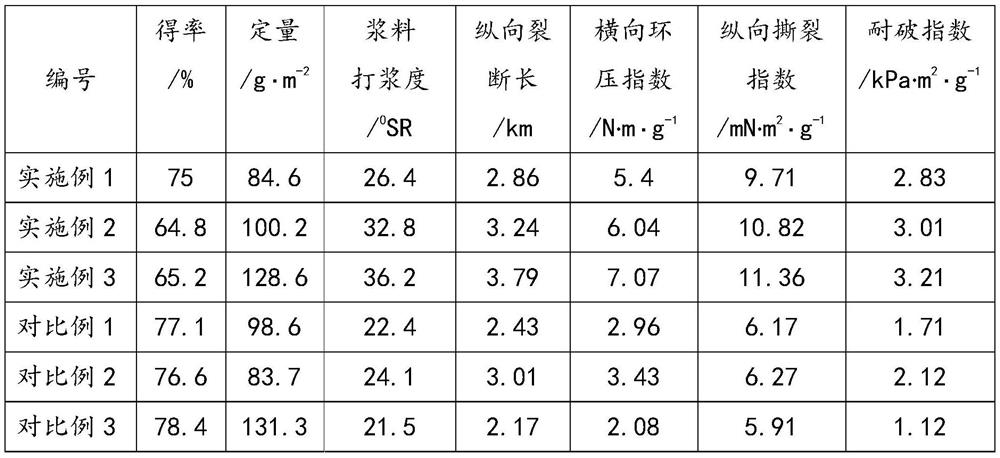

Examples

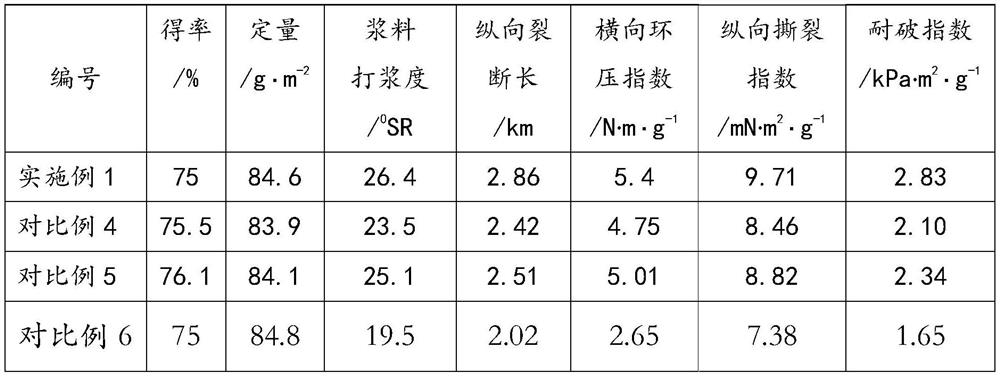

Embodiment 1

[0052] A preparation method of natural color bamboo fiber biochemical mechanical pulp, comprising the following steps:

[0053] (1) The raw material is prepared by dry method, and the raw bamboo is cut into 10-50mm long and 5-20mm wide bamboo slices; after screening, the large pieces sifted out are then cut to make them reach 10-50mm long and 5-20mm wide Size, pass rate of more than 85%. Screened bamboo chips, bamboo pith, knots and other fine debris are used when the bamboo chips are fermented.

[0054] (2) The qualified bamboo chips after screening are sent into a press for pre-pressing, the pre-pressing pressure is 2.5MPa, the pressing time is 10min, and the temperature is normal temperature.

[0055] (3) Bamboo chip fermentation: wet the pre-pressed bamboo chips with water to make the water content 45%-55%; finely crush the water-moistened bamboo chips together with the shavings, pith, knots, etc. The sundries are mixed with cow dung, sheep dung, horse dung, pig dung and o...

Embodiment 2

[0072] A preparation method of natural color bamboo fiber biochemical mechanical pulp, comprising the following steps:

[0073] (1) Prepare materials by dry method, cut bamboo into 10-50mm in length and 5-20mm in width; after screening, the sieved large pieces are then cut to make it reach the size of 10-50mm in length and 5-20mm in width, qualified The rate is over 85%. The screened bamboo chips, bamboo pith, knots and other fine debris are used for later fermentation.

[0074] (2) Qualified bamboo chips after screening are sent to an extruder for extruding, the pre-extruding pressure is 5.0MPa, the extruding time is 2min, and the temperature is normal temperature.

[0075] (3) Bamboo slice fermentation: add water to the pre-pressed bamboo slices to make the water content 45%-55%; add water to moisten the bamboo slices together with the shavings, pith, knots, etc. The sundries are mixed with cow manure, sheep manure, horse manure, pig manure and other animal manure accordin...

Embodiment 3

[0085] A preparation method of natural color bamboo fiber biochemical mechanical pulp, comprising the following steps:

[0086] (1) Cut the bamboo into 10-50mm long and 5-20mm wide. After screening, the qualified bamboo chips are sent to the press for pressing. The pre-pressing pressure is 3.5 MPa, the pressing time is 6 minutes, and the temperature is normal temperature.

[0087] (2) Bamboo chip fermentation: the pre-pressed bamboo chips, together with fine debris such as shavings, pith, and knots, are mixed with animal manure such as cow dung, sheep manure, horse manure, and pig manure at a ratio of 6:4. Stir evenly, and after mixing evenly, pile up long strips with a length of 2-2.5m, a width of 1.5-2m, and a height of 0.8-1m, and cover them with sacks for aerobic fermentation. While mixing, add 2% high-efficiency active biological compound bacteria relative to the mass of the dry bamboo slices for fermentation. The fermentation time is 96 hours, and the moisture content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com