A method for electroless nickel-phosphorus plating of quartz fibers

A technology of electroless nickel phosphorus and quartz fiber plating, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of complex process and high cost, achieve simplified process flow, strong coating adhesion, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

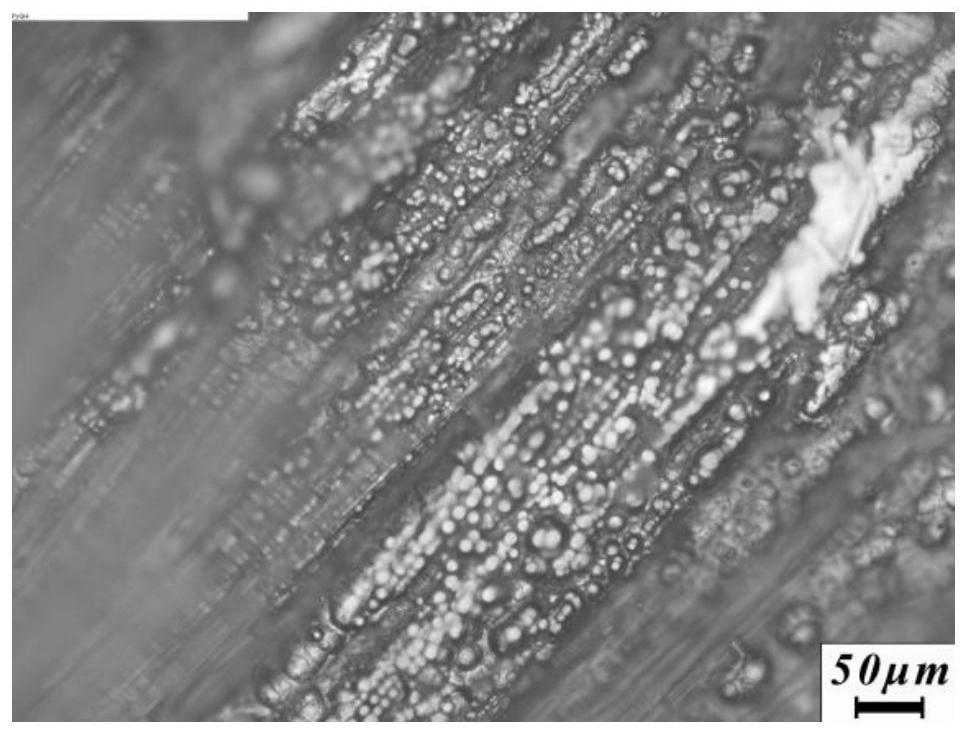

Image

Examples

Embodiment 1

[0023] (1) the preparation concentration is the nickel sulfate hexahydrate of 30g / L, sodium hypophosphite monohydrate of 30g / L, sodium acetate trihydrate of 22g / L, citric acid of 18g / L and ammonium bifluoride of 16g / L earlier aqueous solution, and then adjust the pH of the aqueous solution to 6.5 with ammonia water to obtain a plating solution;

[0024] (2) Transfer the plating solution prepared in step (1) to a fluorinated plastic container, and then place it on a 85-2a digital display constant temperature magnetic stirring heater to heat the plating solution to 80°C;

[0025] (3) Fix the 95tex quartz fiber in the beaker, and place the rotor on the quartz fiber, add the plating solution heated in step (2), then place the beaker on the 85-2a digital display constant temperature magnetic stirring heater to keep 80 ℃ constant temperature, and set the rotor speed to 490r / min, deposit under the friction between the rotor and the quartz fiber, the plating solution turns black after...

Embodiment 2

[0031] On the basis of the embodiment, the rotor speed in the embodiment 1 is replaced by 280r / min by 490r / min, other steps and deposition conditions are constant, the plating solution starts to turn black when depositing for 40min, and the nickel-phosphorus coating is obtained on the quartz fiber .

[0032] Due to the mechanical grinding effect of the rotor and the quartz fiber, the nickel-phosphorus, which has a weak binding force with the quartz fiber, enters the plating solution, thereby causing the spontaneous decomposition of the coating. Therefore, the instantaneous decomposition of the nickel-phosphorus coating can be used as a quantitative indicator when deposited to a certain extent. From Example 1 and Example 2, it can be seen that the faster the rotor speed is, the faster the coating is deposited.

Embodiment 3

[0034] (1) the preparation concentration is the nickel sulfate hexahydrate of 30g / L, sodium hypophosphite monohydrate of 30g / L, sodium acetate trihydrate of 22g / L, citric acid of 18g / L and ammonium bifluoride of 12g / L earlier aqueous solution, and then adjust the pH of the aqueous solution to 6.5 with ammonia water to obtain a plating solution;

[0035] (2) Transfer the plating solution prepared in step (1) to a fluorinated plastic container, and then place it on a 85-2a digital display constant temperature magnetic stirring heater to heat the plating solution to 80°C;

[0036] (3) Fix the 95tex quartz fiber in the beaker, and place the rotor on the quartz fiber, add the plating solution heated in step (2), then place the beaker on the 85-2a digital display constant temperature magnetic stirring heater to keep 80 ℃ constant temperature, and set the rotor speed to 280r / min, deposit under the friction between the rotor and the quartz fiber, the plating solution turns black after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com