Graphene-based hybrid multilayer structure fiber material, preparation thereof and application

A fiber material and multi-layer structure technology, which is applied in the fields of carbon fiber, fiber processing, and analysis materials, can solve the problems of high cost and complicated preparation process, and achieve the effects of short time consumption, high sensitivity and detection range, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

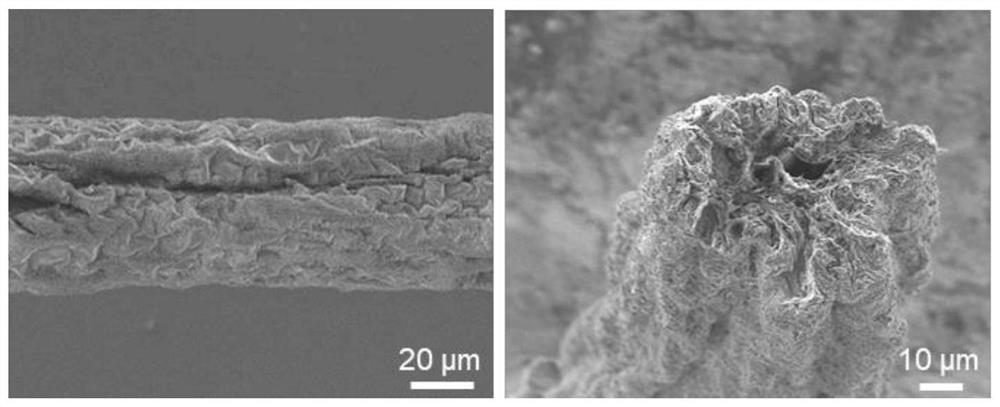

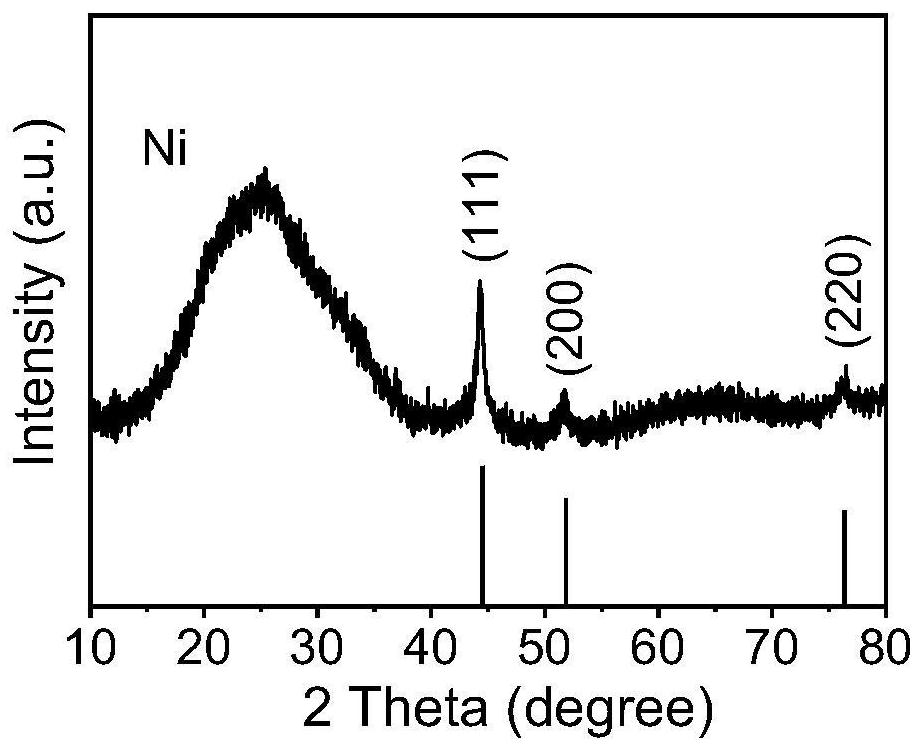

[0036] Put the oxidized graphene water dispersion (15 mg / ml) into nitrate (Ni (Ni (Ni (Ni) having a rotational speed of 5% by 5% by 5% by 5% by 5% by 5% by 400 μl / min. 3 ) 2 · 6h 2 O) Ni will be obtained in solution 2+ Cross-linked GO fibers are removed from the coagulation bath and place 12h at room temperature. The resulting RGO fibers were mixed with 200 mg of melamine and placed in a crucible in a hydrated carbide solution atmosphere. 2The tube furnace under the atmosphere was thermally reduced, and the heating rate was 5 ° C / min, 700 ° C for 0.5 h, resulting in the final product. At this time, CNT was grown in situ in RGO fibers under Ni catalysis.

[0037] The graphene-based multilayer structure fiber material prepared in this example can be used as a sensor conductive material, first mixing the PDMS main agent and the hardener in mass than 10: 1, even on the polytetrafluoroethoate. After drying as a sensor substrate. The copper wires of the two diameter diameter of ...

Embodiment 2

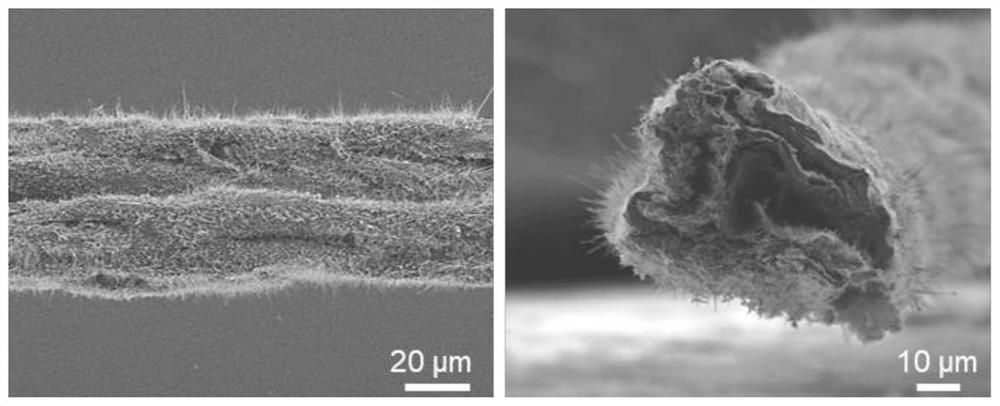

[0041] Put the cobalt nitrate (CO (NO (NO) having a rotational speed of 5% by 5% by 5% a rotational speed of 5% by 5% by 5% by 400 μl / min. 3 ) 2 · 6h 2 O) Ni will be obtained in solution 2+ Cross-linked GO fibers are removed from the coagulation bath and place 12h at room temperature. The resulting RGO fibers were mixed with 200 mg of melamine and placed in a crucible in a hydrated carbide solution atmosphere. 2 The tube furnace under the atmosphere was thermally reduced, and the heating rate was 5 ° C / min, 700 ° C for 0.5 h, resulting in the final product. At this time, CNT was grown in situ in the RGO fiber under the catalysis of CO.

[0042] In contrast to Example 1: The length of the CNTs of the fiber surface is small, poor density, and the conductivity of the fibers is lower than that of the obtained hybrid multilayer structural fiber material obtained under Ni catalysis, and thereby causing the performance of the sensor. difference.

Embodiment 3

[0044] The water dispersion (15 mg / ml) of oxidized graphene is extruded into a nitrate having a rotational speed of 5% by 5% by 5% by 400 μl / min (FE (NO). 3 ) 3 · 9h 2 O) Ni will be obtained in solution 2+ Cross-linked GO fibers are removed from the coagulation bath and place 12h at room temperature. The resulting RGO fibers were mixed with 200 mg of melamine and placed in a crucible in a hydrated carbide solution atmosphere. 2 The tube furnace under the atmosphere was thermally reduced, and the heating rate was 5 ° C / min, 700 ° C for 0.5 h, resulting in the final product. At this time, CNT was grown in situ in the RGO fibers under the catalysis of Fe.

[0045] In contrast to Example 1: The length of the CNTs of the fiber surface is small, poor density, and the conductivity of the fibers is lower than that of the obtained hybrid multilayer structural fiber material obtained under Ni catalysis, and thereby causing the performance of the sensor. difference.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com