Method for surface modification by carbon fiber chemical nickel-plating

A technology of surface modification and electroless nickel plating, which is applied in the direction of carbon fiber, liquid chemical plating, fiber treatment, etc., can solve the problems of low reactivity, low surface energy of carbon fiber, poor matrix adhesion and wettability, etc., and achieve good microscopic Structure, the effect of increasing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

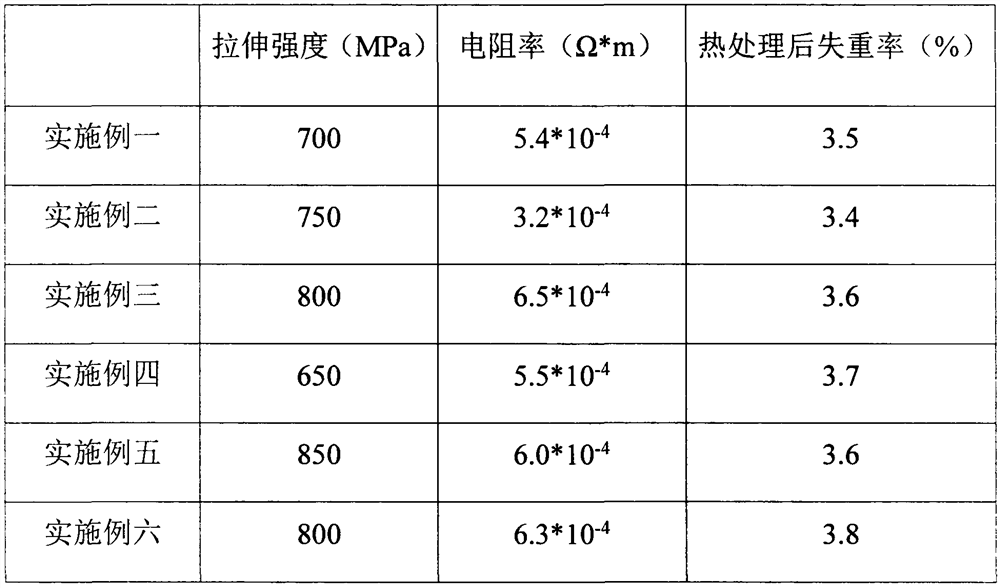

Examples

Embodiment 1

[0014] Carbon fiber is carried out the method for surface modification then electroless nickel plating, comprises the following steps:

[0015] (1) Degumming, put the carbon fiber in a muffle furnace for high-temperature burning at 300°C for 30min.

[0016] (2) Coarse, soak the carbon fiber after degumming in step (1) in a mixed solution of hydrofluoric acid and concentrated phosphoric acid with a volume fraction of 10% for 30 minutes, then take it out, wash it with deionized water until neutral, and dry it for use .

[0017] (3) sensitization, the carbon fiber after step (2) roughening is soaked in the SnCl that mass concentration is 5% 2 In the solution for 15min, then take it out and wash it with deionized water until neutral, and dry it for use.

[0018] (4) Activation, palladium chloride, ammonium chloride, sodium hypophosphite were mixed and stirred for 10min to prepare an activation solution, the concentration of palladium chloride was 0.5g / L, the concentration of amm...

Embodiment 2

[0021] Carbon fiber is carried out the method for surface modification then electroless nickel plating, comprises the following steps:

[0022] (1) Degumming, put the carbon fiber in a muffle furnace for high-temperature burning at 400°C for 20min.

[0023] (2) Coarse, soak the carbon fiber after degumming in step (1) in a mixed solution of hydrofluoric acid and concentrated phosphoric acid with a volume fraction of 15% for 20 minutes, then take it out, wash it with deionized water until neutral, and dry it for use .

[0024] (3) Sensitization, immerse the roughened carbon fiber in step (2) in a SnCl2 solution with a mass concentration of 10% for 20 minutes, then take it out and wash it with deionized water until it is neutral, and dry it for use.

[0025] (4) activation, palladium chloride, ammonium chloride, sodium hypophosphite were mixed and stirred for 10min to prepare activation solution, the concentration of palladium chloride was 1g / L, the concentration of ammonium ch...

Embodiment 3

[0028] Carbon fiber is carried out the method for surface modification then electroless nickel plating, comprises the following steps:

[0029] (1) Degumming, put the carbon fiber in a muffle furnace for high-temperature burning at 500°C for 10 minutes.

[0030] (2) Coarse, soak the carbon fiber after degumming in step (1) in a mixed solution of hydrofluoric acid and concentrated phosphoric acid with a volume fraction of 20% for 10 minutes, then take it out, wash it with deionized water until neutral, and dry it for use .

[0031] (3) Sensitization, immerse the roughened carbon fiber in step (2) in a SnCl2 solution with a mass concentration of 15% for 30 minutes, then take it out and wash it with deionized water until neutral, and dry it for use.

[0032] (4) Activation, palladium chloride, ammonium chloride, sodium hypophosphite were mixed and stirred for 10min to prepare an activation solution, the concentration of palladium chloride was 1.5g / L, the concentration of ammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com