Seamlessly-woven radiation-proof down jacket and manufacturing method

A technology for radiation protection and down jackets, applied in the field of down jacket processing, can solve the problems of poor wearing performance, rough hand feel, easy falling off of metal coatings, etc. The effect of anti-radiation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

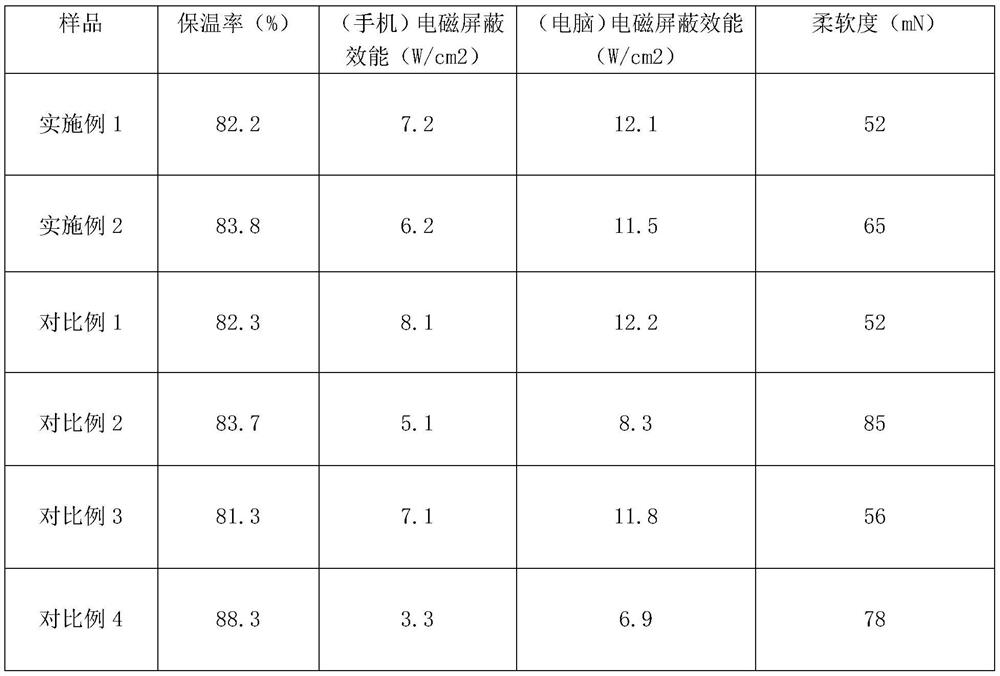

Examples

Embodiment 1

[0023] A seamlessly woven anti-radiation down jacket, including an inner shielding layer, an insulation layer, and an outer shielding layer bonded sequentially by hot-melt adhesive from the inside to the outside, and the inner shielding layer is made of skin-friendly fabric and metal fiber through plain knitting The insulation layer is a down fiber layer composed of down fibers with an average diameter of 0.8 μm and an acrylic resin adhesive; the outer shielding layer is composed of windproof fabrics and anti-radiation coatings coated on windproof fabrics, and the anti-radiation coatings are made of silica gel. , silicone oil, and boron carbide particles are mixed and vulcanized.

[0024] Specifically, the skin-friendly fabric is an anti-wrinkle fabric, which includes an outer layer and an inner layer. The outer layer is made of blended 30% nylon and 100% polyester fiber, and the inner layer is made of bamboo charcoal fiber fabric. An anti-wrinkle layer is arranged between the...

Embodiment 2

[0039] A seamlessly woven anti-radiation down jacket, including an inner shielding layer, an insulation layer, and an outer shielding layer bonded sequentially by hot-melt adhesive from the inside to the outside, and the inner shielding layer is made of skin-friendly fabric and metal fiber through plain knitting The insulation layer is a down fiber layer composed of down fibers with an average diameter of 0.8 μm and an acrylic resin adhesive; the outer shielding layer is composed of windproof fabrics and anti-radiation coatings coated on windproof fabrics, and the anti-radiation coatings are made of silica gel. , silicone oil, and boron carbide particles are mixed and vulcanized.

[0040] Specifically, the skin-friendly fabric is an anti-wrinkle fabric, which includes an outer layer and an inner layer. The outer layer is made of blended 30% nylon and 100% polyester fiber, and the inner layer is made of bamboo charcoal fiber fabric. An anti-wrinkle layer is arranged between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com