Degradable polyester/polyether block copolymer, polylactic acid degradable composite fiber and preparation method thereof

A technology of polyether block and degrading polyester is applied in the field of textile fibers, which can solve the problems of low impact resistance, poor heat resistance and high cost, and achieve the effects of good toughness and elasticity, low cost and good aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

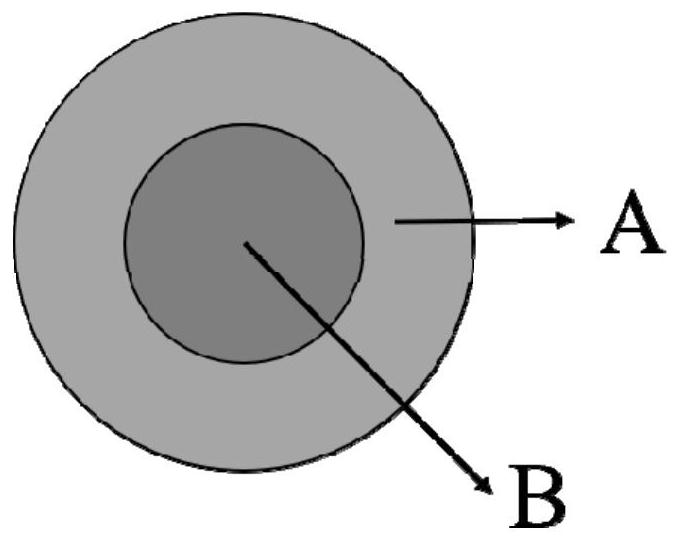

Image

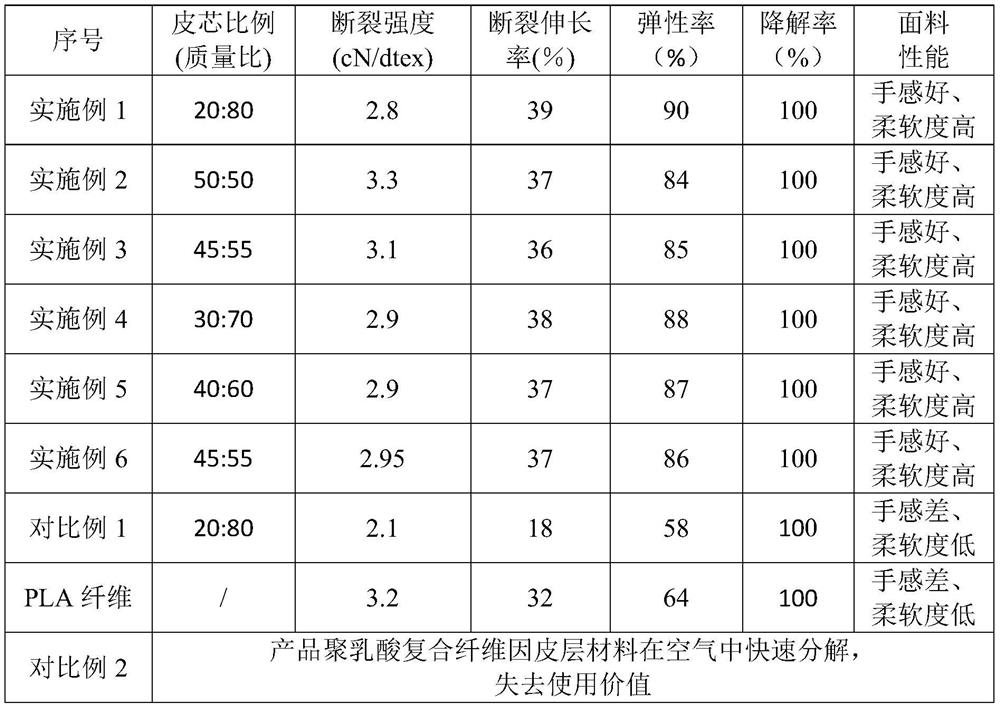

Examples

Embodiment 1

[0038] In this example, 1 mol of terephthalic acid (TPA), 1.5 mol of 1,4-butanediol (BD) and 150 g of PEG polyether with a molecular weight of 1000 are used as the reaction raw materials, and 0.142 g of butyl titanate is added as a catalyst, and the esterification process is carried out directly at 210 ° C. The reaction was carried out for 3 hours. After the esterification was completed, the polycondensation reaction was carried out at 245°C in a vacuum state of 50 Pa. The reaction time was 6 hours to obtain a degradable polyester / polyether block copolymer. The mass ratio of the hard segment PBT / soft segment It was 52.4:47.6.

[0039] The above-mentioned degradable polyester / polyether block copolymer (core layer material) obtained by polymerization and commercially available PLA (skin layer material) slices are fully dried at 100°C; then the dried PLA and degradable polyester / polyether The polyether block copolymer raw materials are melted and extruded through a screw extruder...

Embodiment 2

[0042] In this example, 1mol of terephthalic acid (TPA), 1.5mol of 1,4 butanediol (BD) and 81g of polytetrahydrofuran ether glycol (PTMG) of 2500 molecular weight are used as reaction raw materials, and 0.192g of butyl titanate is added as a catalyst. The esterification reaction was carried out directly at 200°C for 4 hours. After the esterification, the polycondensation reaction was carried out at 250°C in a vacuum state of 100 Pa. The reaction time was 4 hours to obtain a degradable polyester / polyether block copolymer, in which the hard segment PBT / soft The mass ratio of chain segments is 71.4:28.6.

[0043] The above-mentioned degradable polyester / polyether block copolymer (core layer material) obtained by polymerization and commercially available PLA (skin layer material) slices were fully dried at 60°C; then the dried PLA and degradable polyester / polyether The polyether block copolymer raw materials are melted and extruded through a screw extruder, and the polylactic acid...

Embodiment 3

[0045] In this example, 1mol of terephthalic acid (TPA), 1.5mol of 1,4-butanediol (BD) and 61g of 500 molecular weight propylene oxide diol (PPG) are used as reaction raw materials, and 0.362g of butyl titanate is added as a catalyst. The esterification reaction was carried out directly at 230°C for 2 hours. After the esterification was completed, the polycondensation reaction was carried out at 235°C in a vacuum state of 10 Pa. The reaction time was 4 hours to obtain a degradable polyester / polyether block copolymer, in which the hard segment PBT / soft The mass ratio of chain segments is 71.4:28.6.

[0046] The above-mentioned degradable polyester / polyether block copolymer (core layer material) obtained by polymerization and commercially available PLA (skin layer material) slices were fully dried at 60°C; then the dried PLA and degradable polyester / polyether The polyether block copolymer raw materials are melted and extruded through a screw extruder, and the polylactic acid wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com