Environment protection type coating discharge printing pulp and discharge printing process thereof

A discharge printing and environment-friendly technology, which is applied in the field of environment-friendly discharge printing paste for discharge printing and its discharge printing process, can solve the problems of poor hand feeling of discharge printing of paint and poor color fastness of discharge printing, and achieves Solve the effect of color light and heat instability and poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

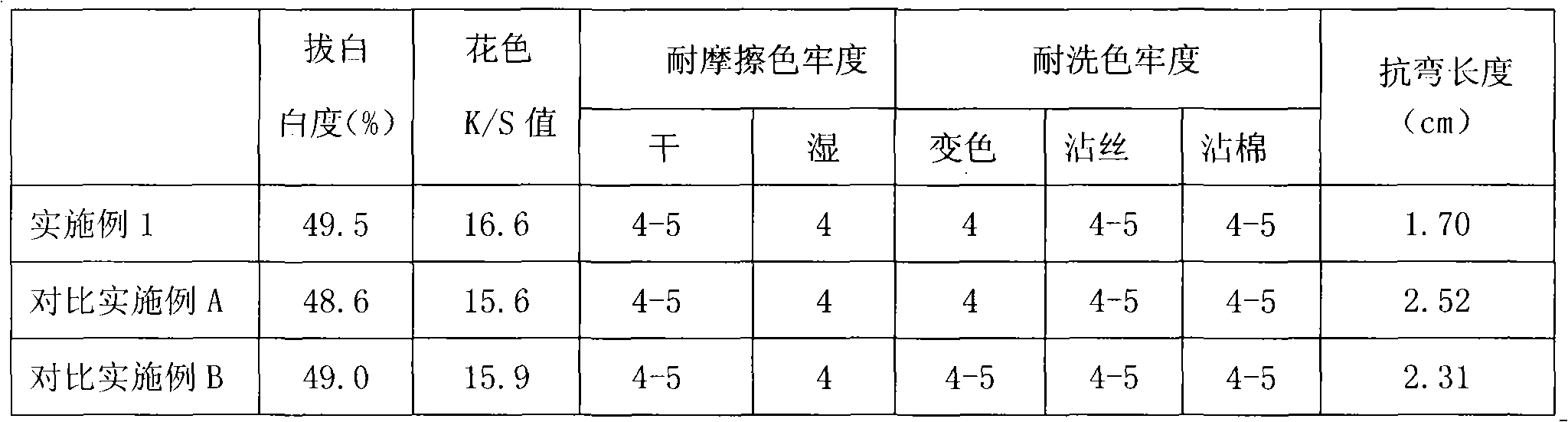

Embodiment 1

[0032] (1) Fabric preparation: silk crepe chine fabric dyed with weakly acid brilliant orange GS dye.

[0033] (2) Preparation of composite thickening slurry: add 150 g of thickening slurry containing 3.5% synthetic thickener PFL produced by Shanghai Yuhui Chemical Co., Ltd., and 3% synthetic thickener produced by Ciba Fine Chemical Co., Ltd. in a 500ml beaker Add 150 g of thickened slurry of agent PT-RV, stir evenly to make 300 grams of compound thickened slurry, set aside.

[0034] (3) Preparation of whitening pulp: add 100 g of the above-mentioned composite thickening pulp into a 200 ml beaker, then add 5 g of thiourea dioxide, 5 g of urea and 1.5 g of softener, and stir evenly to make whitening pulp.

[0035] (4) Preparation of color drawing pulp: add 100g of composite thickening pulp into a 200ml beaker, then add 5g of thiourea dioxide, 5g of urea, 20g of adhesive APF101, 2g of printing and bleaching fast green K-GC, softener 1.5g , and stir evenly to make the discharge ...

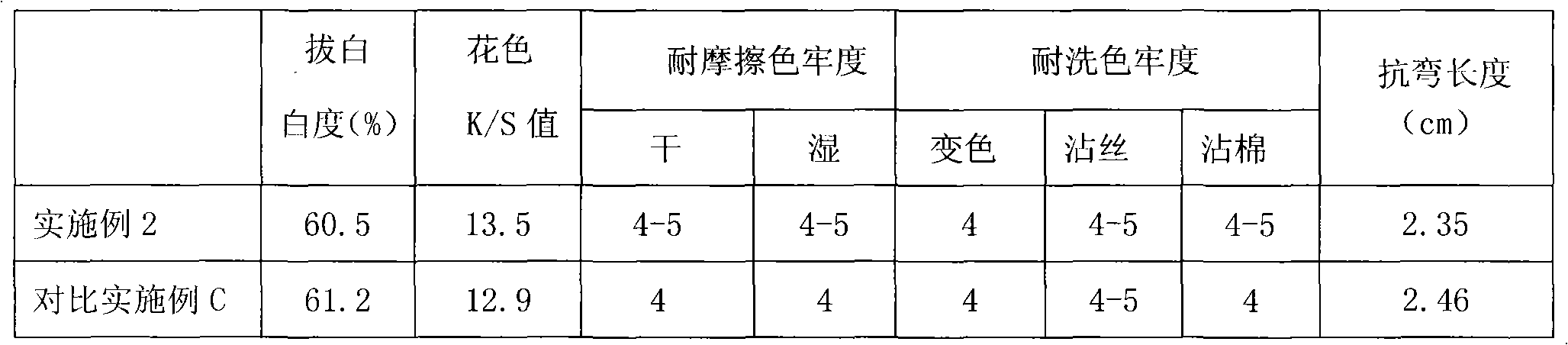

Embodiment 2

[0042] (1) Fabric preparation: Cotton fabric dyed with golden RNL dyes of DyStar Remazol series.

[0043] (2) Preparation of composite thickening slurry: add 150 g of thickening slurry containing 3.5% synthetic thickener PFL produced by Shanghai Yuhui Chemical Co., Ltd., and 3% synthetic thickener produced by Ciba Fine Chemical Co., Ltd. in a 500ml beaker Add 150 g of thickened slurry of agent PT-RV, stir evenly to make 300 grams of compound thickened slurry, set aside.

[0044] (3) Preparation of whitening pulp: add 100 g of the above-mentioned composite thickening pulp into a 200 ml beaker, then add 7 g of thiourea dioxide, 5 g of urea and 1.5 g of softener, and stir evenly to make whitening pulp.

[0045] (4) Preparation of color drawing pulp: add 100g of composite thickening pulp into a 200ml beaker, then add 7g of thiourea dioxide, 5g of urea, 20g of adhesive APF101, 2g of printing and bleaching fast green K-GC, softener 1.5g , and stir evenly to make the discharge slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com