Sun-proof and high-flame-retardant polyvinyl chloride cable material

A polyvinyl chloride cable, polyvinyl chloride technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., to achieve the effect of excellent mechanical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

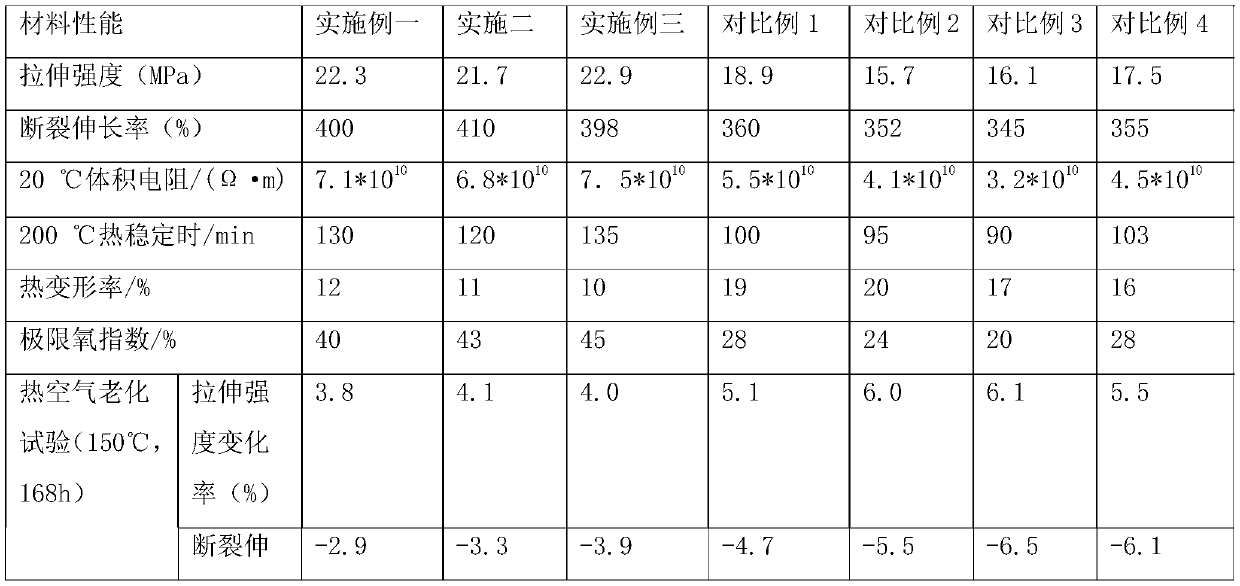

Examples

Embodiment 1

[0021] The sun-resistant high flame-retardant polyvinyl chloride cable material of this embodiment includes the following components by weight: 40 parts of polyvinyl chloride, 10 parts of sodium lauryl sulfate, 5 parts of methyl vinyl silicone rubber, rice 3 parts of fatty acid polyester, 20 parts of plasticizer, 20 parts of filler, 1 part of composite stabilizer, 0.1 part of lubricant, 0.1 part of composite flame retardant, 0.1 part of ultraviolet absorber, 0.1 part of antioxidant, 0.3 part of coloring agent.

[0022] The composite flame retardant is 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and poly 1-butyl-3-(1-vinylimidazole-3-hexyl)imidazole A mixture of sodium hydrogen phosphate, by weight ratio 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide: poly 1-butyl-3-(1-vinylimidazole-3- Hexyl)imidazole sodium hydrogen phosphate=1:2; the plasticizer is cyclohexane-1,2-diisononyl dicarboxylate, 2-methyl 1,3-propanediol dimethacrylate and cardanol Mixture of acetates,...

Embodiment 2

[0025] The sun-resistant high flame-retardant polyvinyl chloride cable material of this embodiment includes the following components by weight: 50 parts of polyvinyl chloride, 20 parts of sodium lauryl sulfate, 10 parts of methyl vinyl silicone rubber, rice 6 parts of fatty acid polyester, 30 parts of plasticizer, 30 parts of filler, 3 parts of composite stabilizer, 1 part of lubricant, 1 part of composite flame retardant, 1 part of ultraviolet absorber, 0.5 part of antioxidant, 0.6 part of coloring agent.

[0026] The composite flame retardant is 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and poly 1-butyl-3-(1-vinylimidazole-3-hexyl)imidazole A mixture of sodium hydrogen phosphate, by weight ratio 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide: poly 1-butyl-3-(1-vinylimidazole-3- Hexyl)imidazole sodium hydrogen phosphate=1:2; the plasticizer is cyclohexane-1,2-diisononyl dicarboxylate, 2-methyl 1,3-propanediol dimethacrylate and cardanol Mixture of acetates, by ...

Embodiment 3

[0029] The sun-resistant high flame-retardant polyvinyl chloride cable material of this embodiment includes the following components by weight: 40 parts of polyvinyl chloride, 20 parts of sodium lauryl sulfate, 5 parts of methyl vinyl silicone rubber, rice 6 parts of fatty acid polyester, 20 parts of plasticizer, 30 parts of filler, 1 part of composite stabilizer, 1 part of lubricant, 0.1 part of composite flame retardant, 1 part of ultraviolet absorber, 0.1 part of antioxidant, 0.6 part of coloring agent.

[0030] The composite flame retardant is 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and poly 1-butyl-3-(1-vinylimidazole-3-hexyl)imidazole A mixture of sodium hydrogen phosphate, by weight ratio 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide: poly 1-butyl-3-(1-vinylimidazole-3- Hexyl)imidazole sodium hydrogen phosphate=1:2; the plasticizer is cyclohexane-1,2-diisononyl dicarboxylate, 2-methyl 1,3-propanediol dimethacrylate and cardanol Mixture of acetates, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com