Inner-layer printing and laser composite paper manufacturing technology

A composite paper and laser technology, applied in the direction of lamination, lamination equipment, layered products, etc., can solve the problems of ink fastness, product scratches, etc., to improve production efficiency, enhance competitiveness, solve ink fastness and The effect of product abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

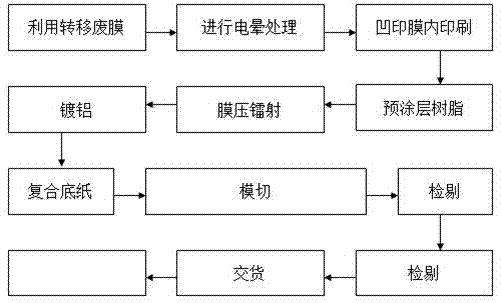

[0031] A kind of inner layer printing laser composite paper manufacturing process is characterized in that, the steps are as follows:

[0032] (1) Corona treatment by transferring waste film:

[0033] The waste film remaining on other laser transfer products can absorb ink after corona treatment, and can be used as a composite film after printing;

[0034] Perform corona on the surface of the printed mask in advance: the temperature is 20°C, the corona resistivity is 10, r]ohm-cm dielectric strength is 16.9Kv / mm, and the surface tension of the printed surface of the film is increased to a value greater than 38 dyne;

[0035] At the same time, the ink factory is required to reduce the internal tension of the ink to ≤36 dynes, which can meet the printing tension requirements of 38 dynes on the film surface;

[0036] After adding the corona process, the waste film after the original transfer and stripping can be reused, which greatly saves the material cost.

[0037] Corona tre...

Embodiment 2

[0053] A kind of inner layer printing laser composite paper manufacturing process is characterized in that, the steps are as follows:

[0054] (1) Corona treatment by transferring waste film:

[0055] The waste film remaining on other laser transfer products can absorb ink after corona treatment, and can be used as a composite film after printing;

[0056] Perform corona on the surface of the printed mask in advance: the temperature is 20°C, the corona resistivity is 10, r]ohm-cm dielectric strength is 16.9Kv / mm, and the surface tension of the printed surface of the film is increased to a value greater than 38 dyne;

[0057] At the same time, the ink factory is required to reduce the internal tension of the ink to ≤36 dynes, which can meet the printing tension requirements of 38 dynes on the film surface;

[0058] After adding the corona process, the waste film after the original transfer and stripping can be reused, which greatly saves the material cost.

[0059] Corona tre...

Embodiment 3

[0075] A kind of inner layer printing laser composite paper manufacturing process is characterized in that, the steps are as follows:

[0076] (1) Corona treatment by transferring waste film:

[0077] The waste film remaining on other laser transfer products can absorb ink after corona treatment, and can be used as a composite film after printing;

[0078] Perform corona on the surface of the printed mask in advance: the temperature is 20°C, the corona resistivity is 10, r]ohm-cm dielectric strength is 16.9Kv / mm, and the surface tension of the printed surface of the film is increased to a value greater than 38 dyne;

[0079] At the same time, the ink factory is required to reduce the internal tension of the ink to ≤36 dynes, which can meet the printing tension requirements of 38 dynes on the film surface;

[0080] After adding the corona process, the waste film after the original transfer and stripping can be reused, which greatly saves the material cost.

[0081] Corona tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com