High-thermal-vacuum-fastness pigment printing process

A pigment printing and vacuum technology, applied in the field of printing and dyeing, to achieve the effect of ensuring uniformity and stability, improving specific surface area and surface activity, and promoting immobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

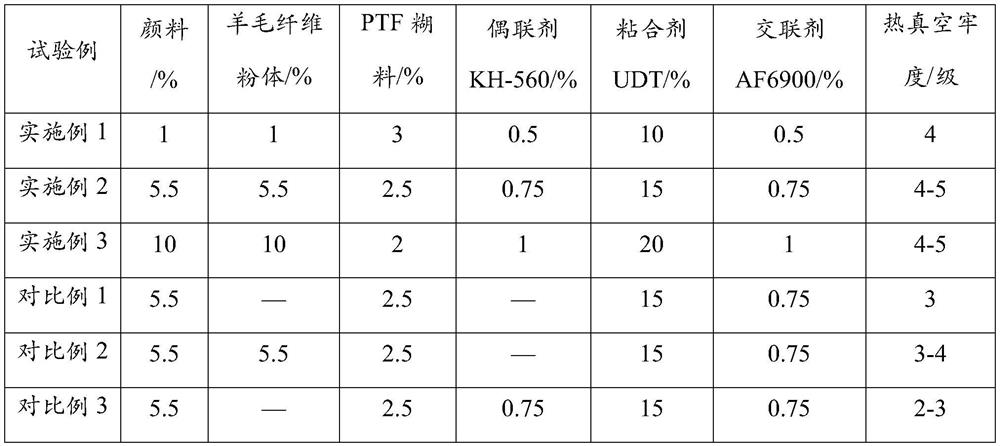

Embodiment 1-3 and comparative example 4-6

[0042] A pigment printing process with high heat and vacuum fastness, including the printing treatment of pigment printing paste and the padding treatment process of water-based polyurethane emulsion (with a particle size of 200-500nm), the prepared pigment printing paste is blended with polyester-cotton fabric Printing, and then padding a layer of water-based polyurethane coating film, post-curing and drying. Among them, pigment printing paste includes by mass percentage:

[0043] 1~10% pigment;

[0044] 1-10% wool fiber powder; the particle size of the wool fiber powder is 35 μm (including intermittent medulla layer);

[0045] 2-3% PTF paste;

[0046] 0.5~1% coupling agent KH-560;

[0047] 10-20% binder UDT;

[0048] 0.5~1% crosslinking agent AF6900;

[0049] The balance is distilled water.

[0050] The configuration method is: S1. Add 1% to 10% of pigment, 1% to 10% of wool fiber powder and 0.5% to 1% of silane coupling agent into distilled water, and stir at a speed ...

Embodiment 4

[0057] A pigment printing process with high heat vacuum fastness, compared with Example 2, the difference is that the wool fiber powder is soaked in 5% ammonia water for 20 minutes. Others are substantially the same as those in Embodiment 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com