Textile product rubbing-resistant structural coloration ink and preparation method thereof

A technology for structural coloring and textiles, which is applied in the field of friction-resistant structural coloring ink for textiles and its preparation, and can solve the problems of poor fastness, reduced area of substrates that can be covered, and lack of mutual adhesion between photonic crystals and substrates. and other problems to achieve the effect of solving poor rubbing fastness and enhancing intermolecular force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

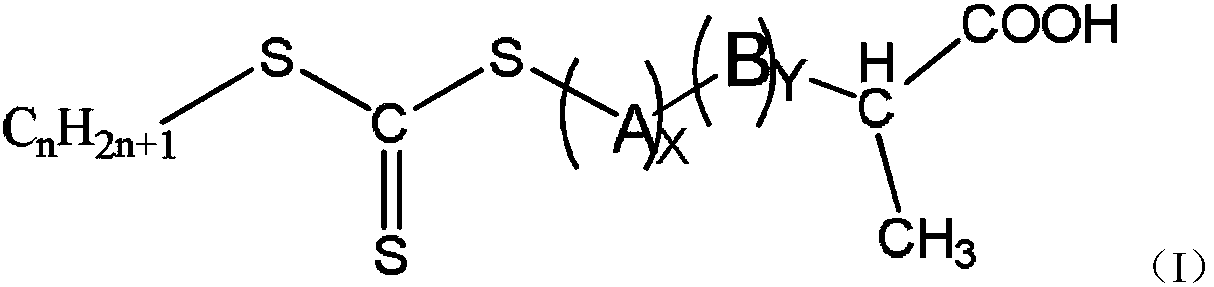

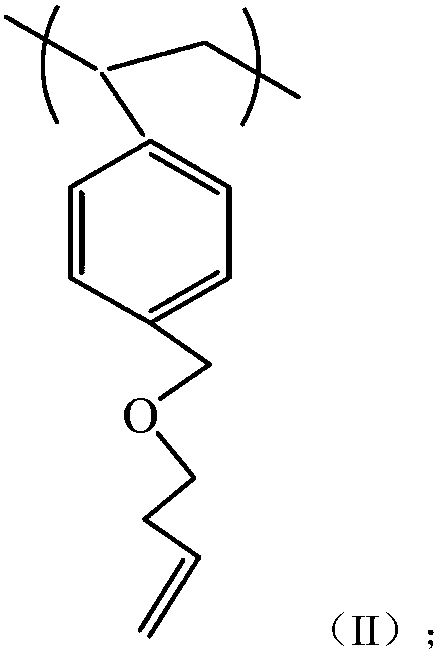

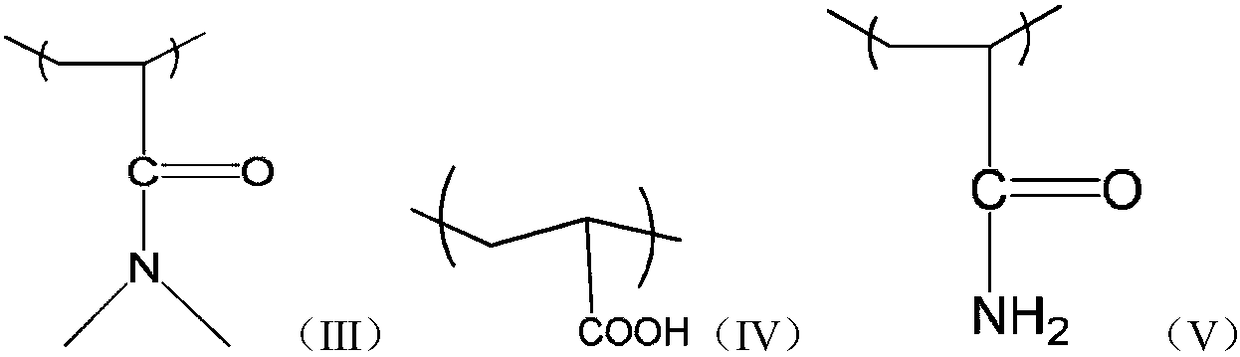

[0038] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is represented by formula (I), where A is represented by formula (II), B is represented by formula (IV), X=5, Y= 50, n=4.

[0039] The preparation steps of friction-resistant structural color ink for textiles are as follows:

[0040] (1) Preparation of reactive rigid colloidal microspheres. Weigh 1.19 g of the macromolecular trithiocarbonate compound in a beaker, then add 75.79 g of deionized water and stir to a homogeneous phase, and finally add 20 g of styrene for emulsification and stirring to obtain a blend system I. The blending system I was placed in a four-necked flask protected by a nitrogen atmosphere at 70° C., and 3.0169 g of potassium persulfate aqueous solution with a mass concentration of 0.56% was added to initiate polymerization, and the reaction was completed for 2 hours to obtain reactive rigid colloidal microspheres.

[0041] (2) Preparation of reactive colloidal adh...

Embodiment 2

[0044] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is represented by formula (I), where A is represented by formula (II), B is represented by (III), X=7, Y=30 , N=12.

[0045] The preparation steps of friction-resistant structural color ink for textiles are as follows:

[0046] (1) Preparation of reactive rigid colloidal microspheres. Weigh 1.84 g of the macromolecular trithiocarbonate compound in a beaker, then add 71.13 g of deionized water and stir to a homogeneous phase, and finally add 24 g of styrene for emulsification and stirring to obtain a blend system I. The blending system I was placed in a four-neck flask protected by a nitrogen atmosphere at 70° C., and 3.027 g of a 0.89% potassium persulfate aqueous solution with a mass concentration of 0.89% was added to initiate polymerization, and the reaction was completed for 3 hours to obtain reactive rigid colloidal microspheres.

[0047] (2) Preparation of reactive colloidal adhe...

Embodiment 3

[0050] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is represented by formula (I), where A is represented by formula (II), B is represented by formula (IV), X=5, Y= 40, n=4.

[0051] The preparation steps of friction-resistant structural color ink for textiles are as follows:

[0052] (1) Preparation of reactive rigid colloidal microspheres. Weigh 1.04 g of the macromolecular trithiocarbonate compound into a beaker, then add 77.95 g of deionized water and stir to a homogeneous phase, and finally add 18 g of methyl methacrylate for emulsification and stirring to obtain a blend system I. The blending system I was placed in a four-necked flask protected by a nitrogen atmosphere at 70° C., and 3.0147 g of an aqueous ammonium persulfate solution with a mass concentration of 0.49% was added to initiate polymerization, and the reaction was completed for 2.5 hours to obtain reactive rigid colloidal microspheres.

[0053] (2) Preparation of reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com