Fabric pigment dyeing and roll-drying resist-dyeing process

A paint dyeing and fabric technology, applied in the field of fabric dyeing, can solve the problems of hard hand feeling, the influence of biochemical treatment of printing and dyeing wastewater, poor color fastness of dyed fabrics, etc., and achieve the effect of solving the effect of dyeing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

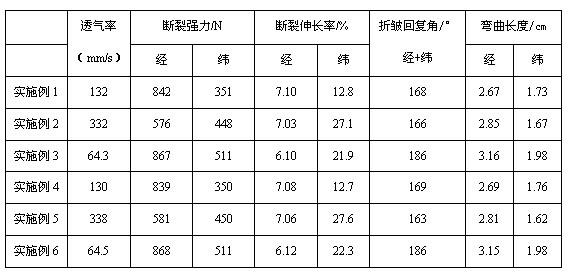

Examples

Embodiment 1

[0028] Use pure cotton twill fabric two-dipping two-padding paint dye solution I on a uniform padding machine, and the excess rate is 60% to 70%, and then dry the fabric with infrared rays or hot air at a drying temperature of 80°C. After the fabric is dried, Then dip the fabric twice with paint dye solution I and roll it twice, the excess rate is 60%~70%, then dry the fabric with infrared ray or hot air, the drying temperature is 80°C, and finally, fix the color at 100°C for 4 minutes; The formula of described paint dye solution I is:

[0029] Paint (A111 Scarlet) 20 g / L

[0030] Low temperature adhesive F5 18 g / L

[0031] Penetrant JFC 0.5 g / L

[0032] Anti-migration agent LE-500 4 g / L

[0033] Softener DT-6400 4 g / L.

Embodiment 2

[0035] Use pure cotton plain fabric two-dipping two-padding paint dye solution I on a uniform padding machine, and the excess rate is 60% to 70%, and then dry the fabric with infrared rays or hot air at a drying temperature of 75°C. After the fabric is dried, Then dip the fabric twice with paint dye solution I and roll it twice, the excess rate is 60%~70%, then dry the fabric with infrared rays or hot air at a drying temperature of 75°C, and finally, fix the color at 110°C for 3 minutes; The formula of described paint dye solution I is:

[0036] Paint (A202 medium yellow) 22 g / L

[0037] Low temperature adhesive F5 20 g / L

[0038] Penetrant JFC 1 g / L

[0039] Anti-migration agent LE-500 3 g / L

[0040] Softener DT-6400 5g / L.

Embodiment 3

[0042] Use 20 / 80 cotton / polyester blended plain weave fabric with double dipping and second padding paint dye solution I on a uniform padding machine, the padding rate is 60%~70%, and then dry the fabric with infrared rays or hot air at a drying temperature of 70°C. After the fabric is dried, the fabric is dipped and rolled twice with the paint dye solution I, and the excess rate is 60%~70%, and then the fabric is dried with infrared rays or hot air at a drying temperature of 70°C, and finally dried at 120°C. Color fixation for 2min; the formula of the paint dye solution I is:

[0043] Paint (A301 blue) 25 g / L

[0044] Low temperature adhesive F5 22 g / L

[0045] Penetrant JFC 1.5 g / L

[0046] Anti-migration agent LE-500 2 g / L

[0047] Softener DT-6400 6 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com