Preparation method of black p-aramid fiber

A para-aramid fiber, black technology, applied in the direction of adding pigments, single-component polyamide artificial filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

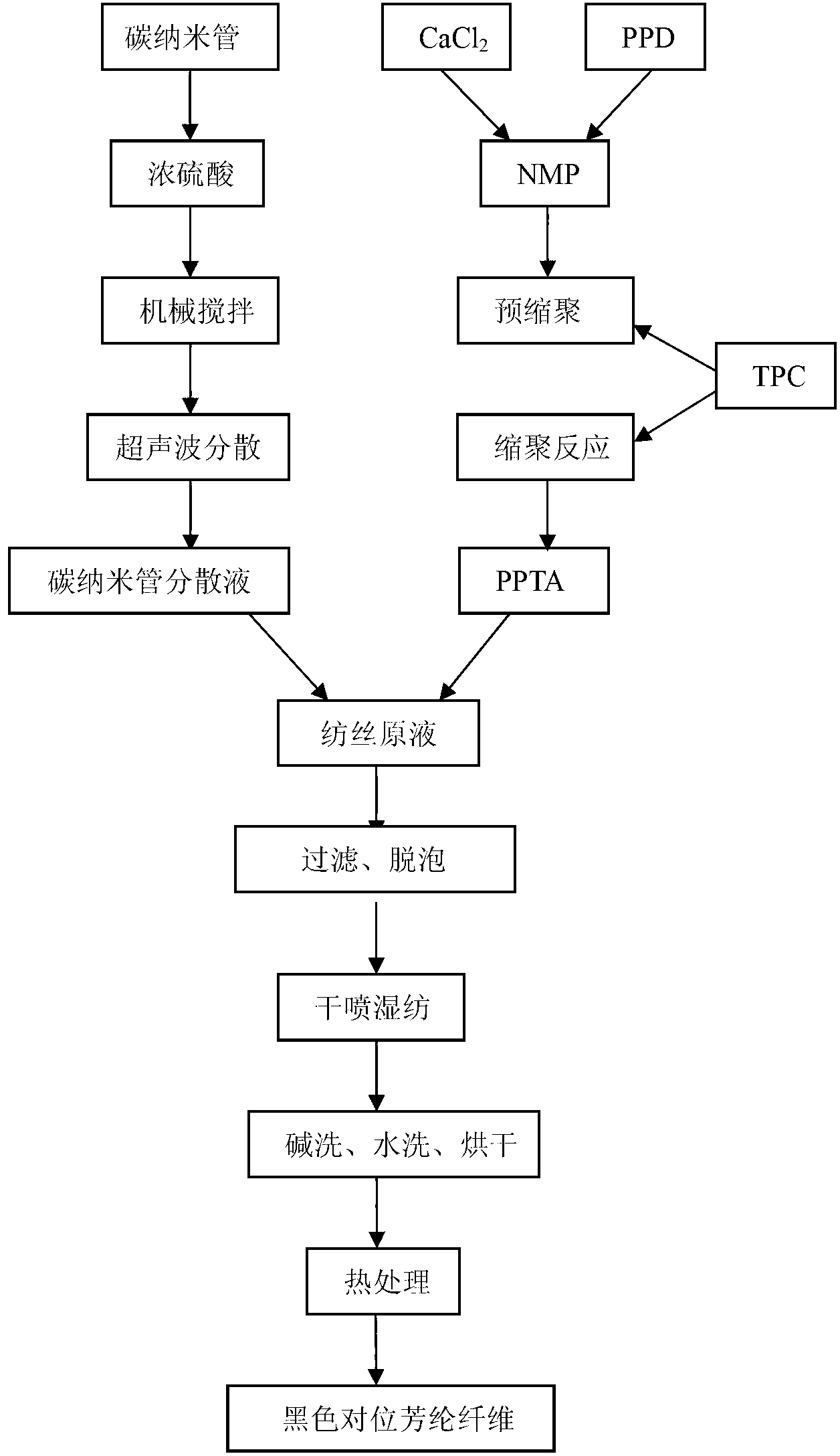

Method used

Image

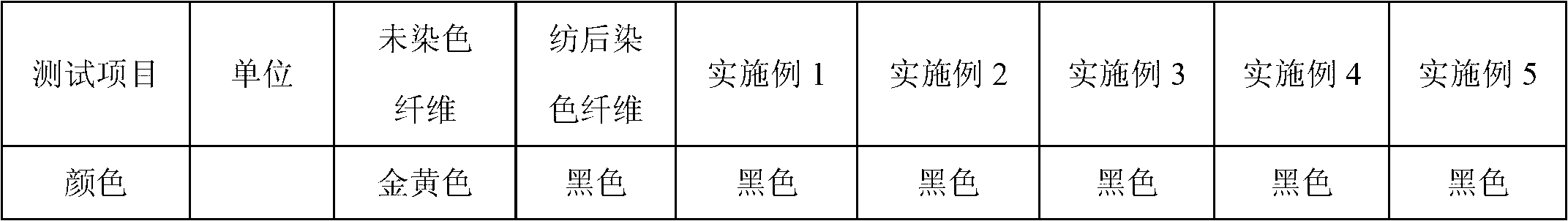

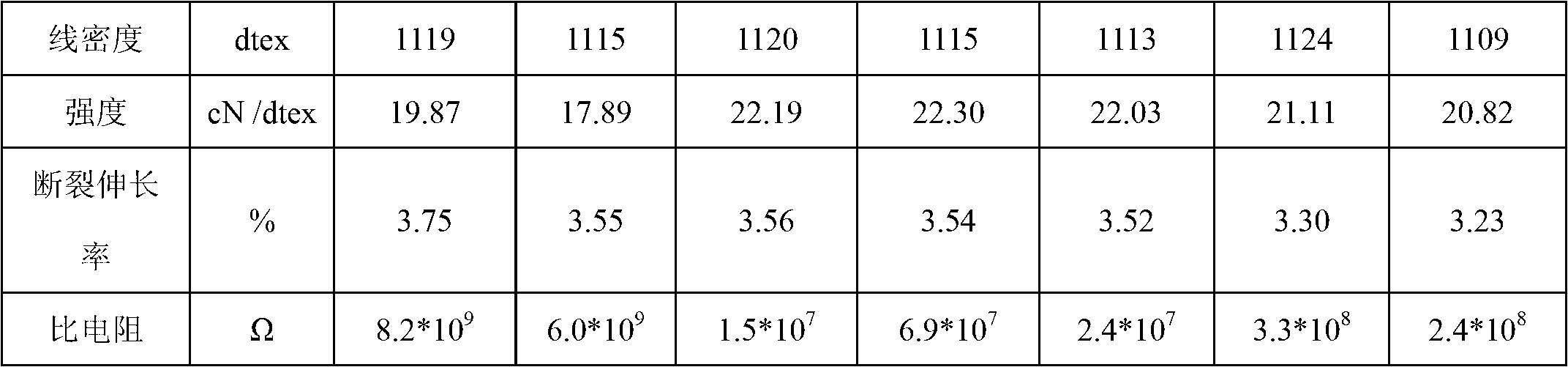

Examples

Embodiment 1

[0030] Get average diameter is 3nm, average length is 15 μ m, average number of walls is 5, unmodified multi-walled carbon nanotube 1.0kg is placed in 500kg 100% mass percentage concentrated sulfuric acid, at first with the stirring speed of 1000rpm stirring 2.0 hours, Then, it was ultrasonicated for 4.0 hours with a power of 60 kHz to form a uniform dispersion of carbon nanotubes;

[0031] Weigh 125 kg of PPTA with an intrinsic viscosity of 7.5 dL / g, and dissolve the PPTA in the carbon nanotube dispersion obtained above through a twin-screw extruder to obtain a spinning stock solution;

[0032] After the spinning dope is filtered and defoamed, the spinneret with a hole diameter of 0.07mm and a hole number of 667 is used for dry spraying and wet spinning, and then alkali washing, water washing, drying and heat treatment to obtain black para-aramid fiber , the heat treatment temperature is 200°C.

[0033] Above-mentioned PPTA is made through the following steps:

[0034] 1. A...

Embodiment 2

[0038]Take 1.0 kg of unmodified multi-walled carbon nanotubes with an average diameter of 3 nm, an average length of 15 μm, and an average number of walls of 4 and place them in 400 kg of 98% by mass concentrated sulfuric acid, and first stir for 1.0 hour at a stirring speed of 1000 rpm , and then ultrasonically sonicate for 3.0 hours with a power of 100kHz to form a uniform carbon nanotube dispersion;

[0039] Weigh 100kg of PPTA with an intrinsic viscosity of 6.5dL / g, and dissolve the PPTA in the carbon nanotube dispersion obtained above through a twin-screw extruder to obtain a spinning stock solution;

[0040] After the spinning dope is filtered and defoamed, the spinneret with a hole diameter of 0.07mm and a hole number of 667 is used for dry spraying and wet spinning, and then alkali washing, water washing, drying and heat treatment to obtain black para-aramid fiber , the heat treatment temperature is 200°C.

[0041] Above-mentioned PPTA is made through the following st...

Embodiment 3

[0046] Take 1.0 kg of unmodified multi-walled carbon nanotubes with an average diameter of 1 nm, an average length of 20 μm, and an average number of walls of 2 and place them in 300 kg of 98% by mass concentrated sulfuric acid, and first stir for 1.0 hour at a stirring speed of 1000 rpm , and then ultrasonically sonicate for 12 hours with a power of 50 kHz to form a uniform dispersion of carbon nanotubes;

[0047] Weigh 75kg of PPTA with an intrinsic viscosity of 6.5dL / g, and dissolve the PPTA in the above-mentioned obtained carbon nanotube dispersion through a twin-screw extruder to obtain a spinning stock solution;

[0048] After the spinning dope is filtered and defoamed, the spinneret with a hole diameter of 0.07mm and a hole number of 667 is used for dry spraying and wet spinning, and then alkali washing, water washing, drying and heat treatment to obtain black para-aramid fiber , the heat treatment temperature is 200°C.

[0049] The preparation method of above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com