Sewing equipment and using method thereof

An equipment and sewing technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve problems such as affecting the sewing effect, unable to automatically collect fabrics, and unable to realize the continuity of the process of mechanized grabbing of fabrics and conveying materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

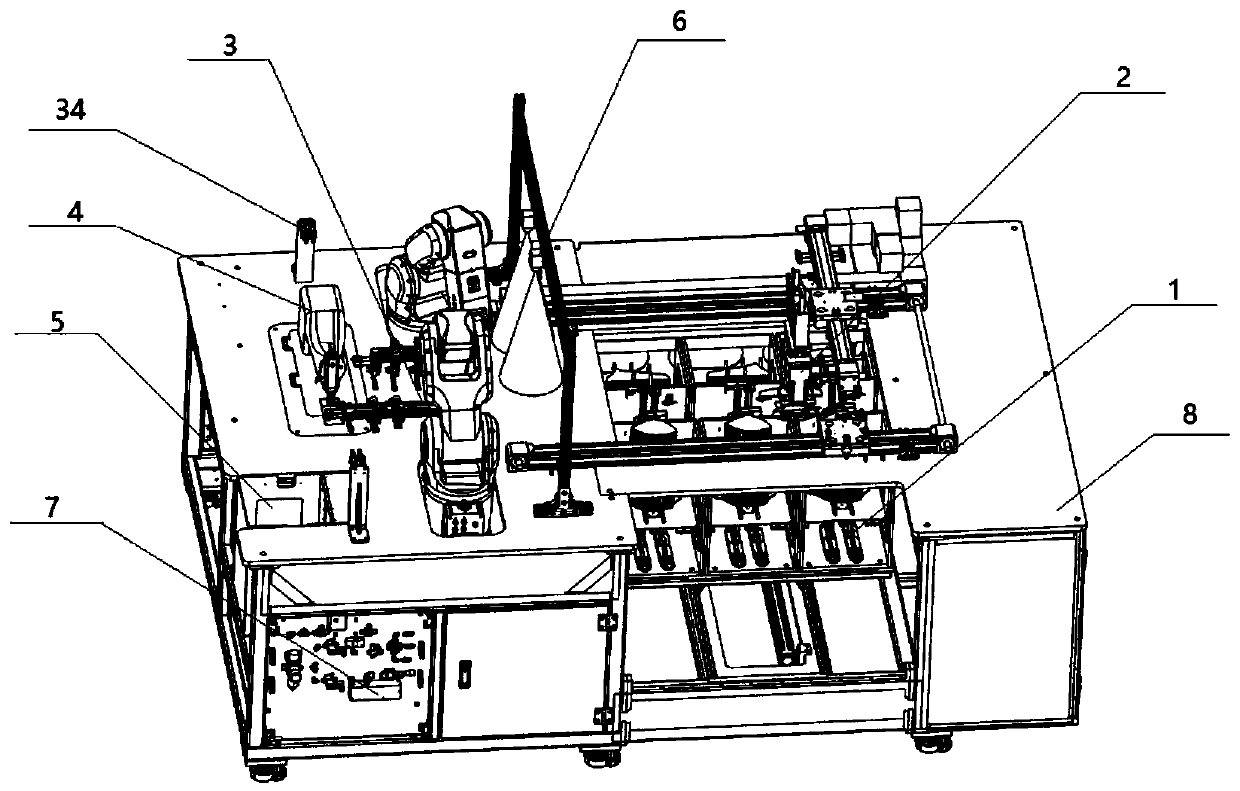

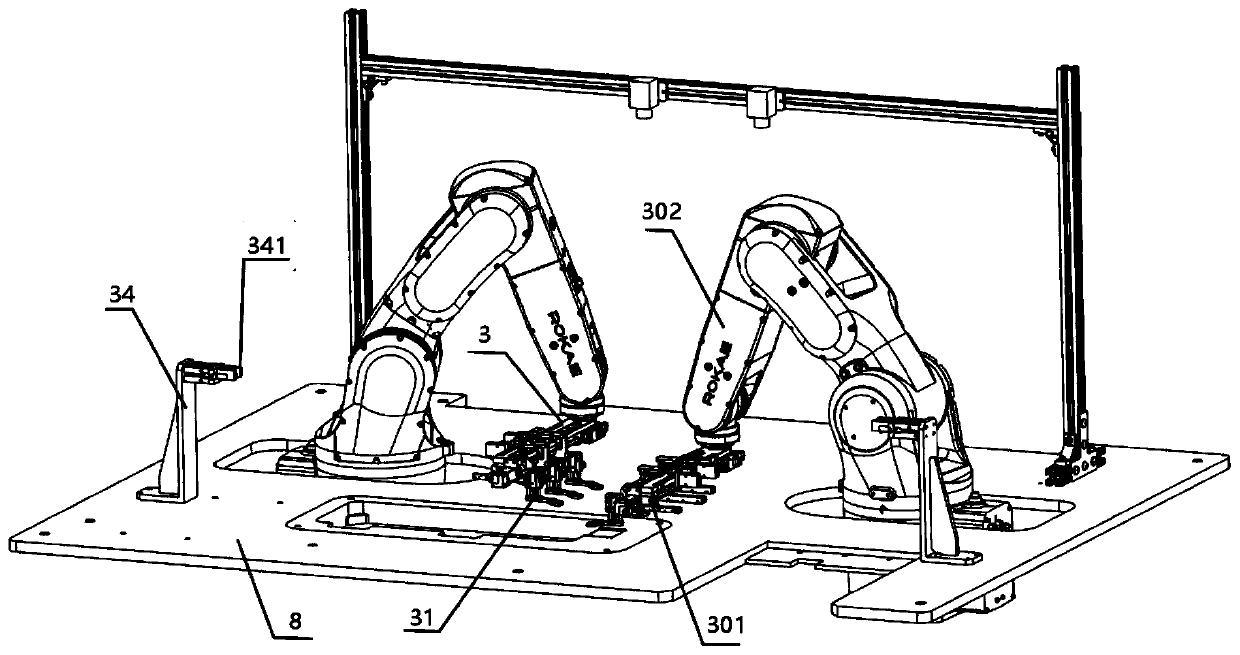

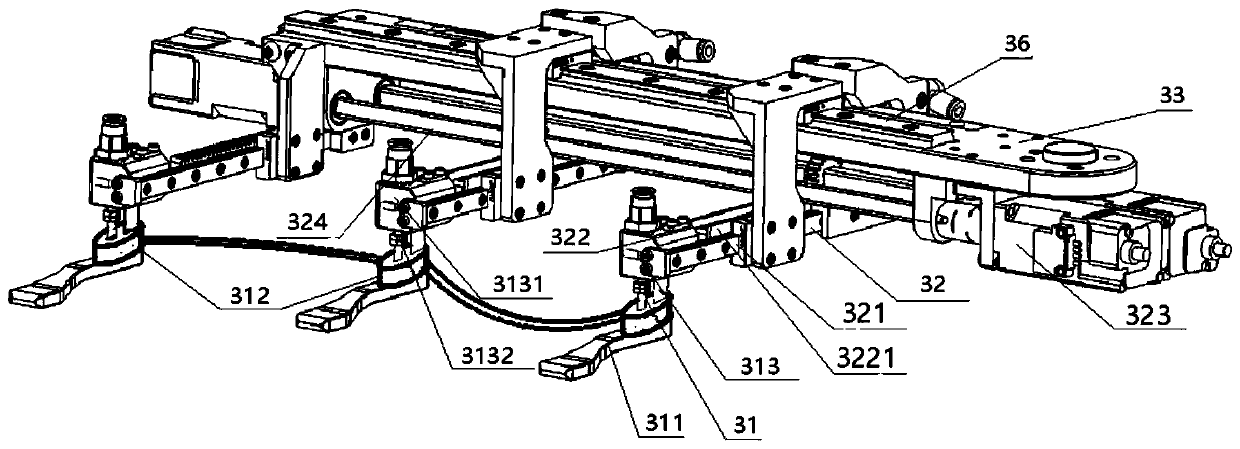

[0069] Such as figure 1As shown, the present invention relates to a sewing device, which includes a workbench 8 and a grasping device 3, a sewing device 4, a visual recognition device 6 and a control system 7 respectively arranged on the workbench 8, and the control system 7 is connected with the grasping device respectively The fetching device 3, the sewing equipment 4 and the visual recognition device 6 are signal-connected and controlled to work. The visual recognition device 6 recognizes the shape of the cloth, and feeds back the shape and size of the cloth to the control system 7. The control system 7 controls the grab device 3 to adjust the grip After taking the angle, the cloth is transported to the sewing equipment 4, the number of grasping devices 3 is greater than or equal to 2, the cloth is transported to the sewing equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com