Micro-nano machining method and device for laser composite ejection liquid beam

A composite jet liquid and micro-nano processing technology, which is applied in laser welding equipment, metal processing equipment, nanotechnology, etc., can solve the problems of low processing efficiency of jet liquid beam, low processing efficiency, difficult removal of abrasive flow, etc., to achieve High-efficiency and high-precision processing effects, elimination of heat-affected zones, and effects of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

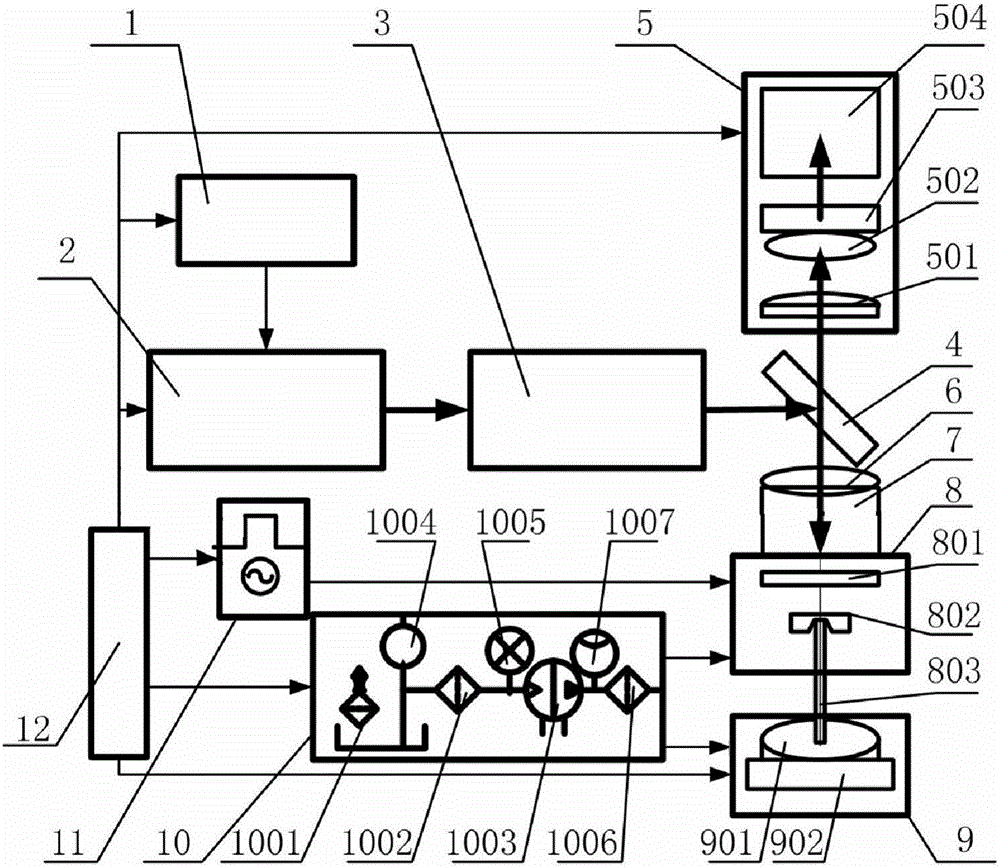

[0073] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0074] The principle of the laser composite jet liquid beam micro-nano processing method of the present invention is as follows:

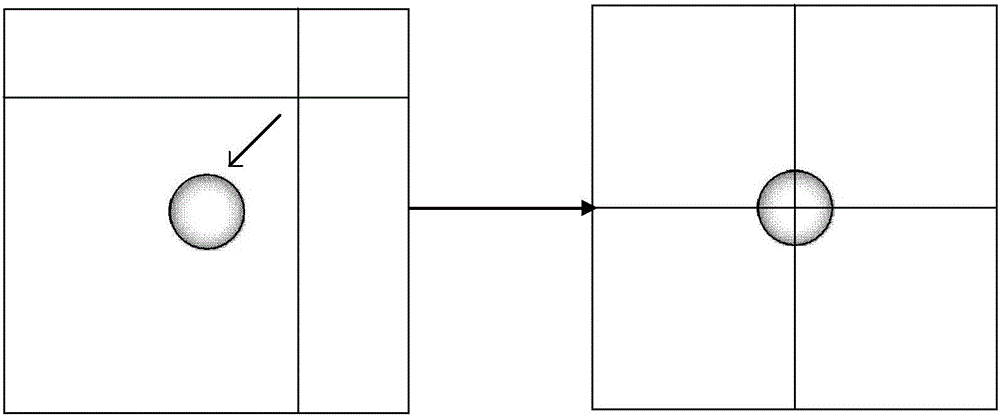

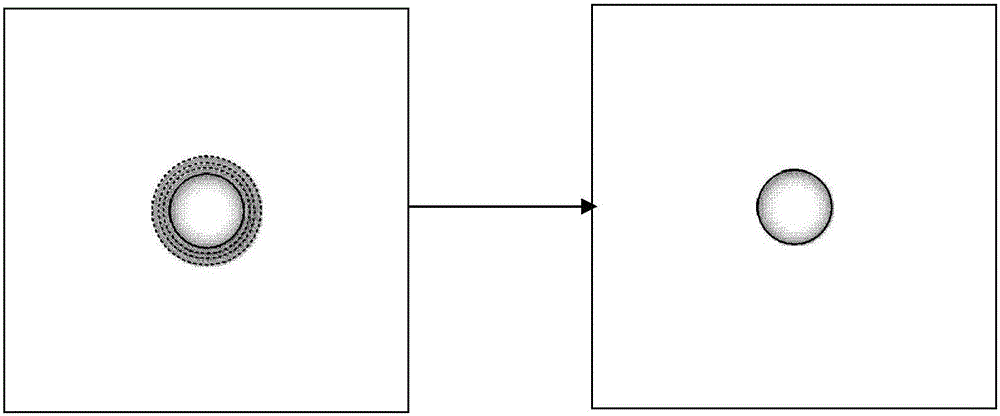

[0075] The advantages of laser processing and jetting liquid beam processing are effectively combined. The laser beam generated by the laser system 2 uses the liquid beam jetted by the jetting device 8 as the medium to process the large aspect ratio micro-nano structure on the workpiece. The function is to remove materials, and the function of jet liquid processing is to "online" eliminate the recast layer, microcracks and residual stress generated during laser processing in the processing area. Because laser processing belongs to gasification processing, although the heat-affected zone is basically eliminated, there are still micro-cracks on the surface. On the basis of laser processing combined with jet li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com