Infrared optical lens component bidirectional transverse alignment processing method and equipment

A technology of infrared optical lens and processing equipment, which is applied in the direction of optical elements, optical elements, optics, etc., can solve the problems of inability to adjust the coaxial ideal optical axis of the two sphere centers, and the inability to observe the images of the two sphere centers of the optical parts at the same time, etc. Achieve the effect of wide applicability and high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

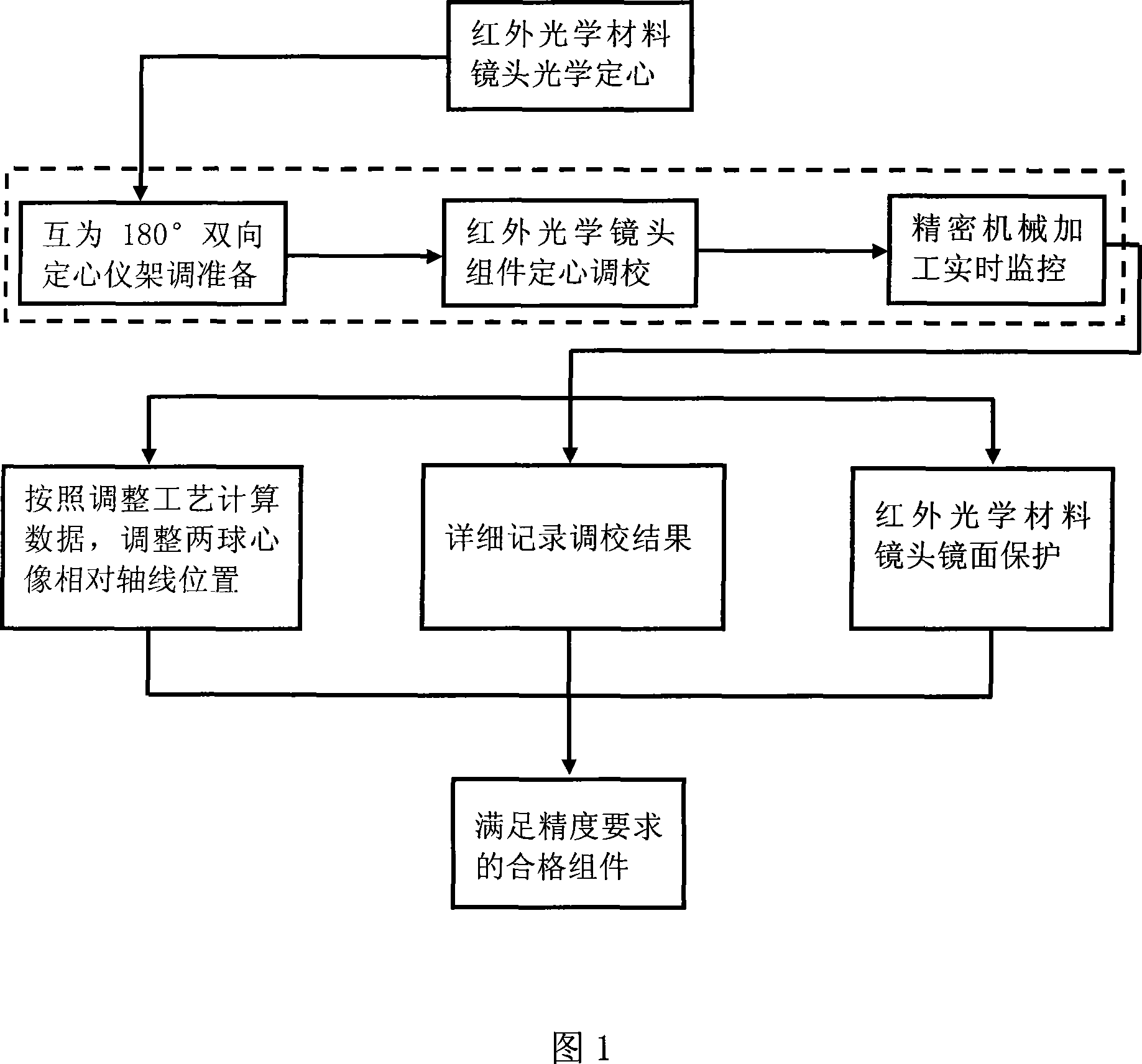

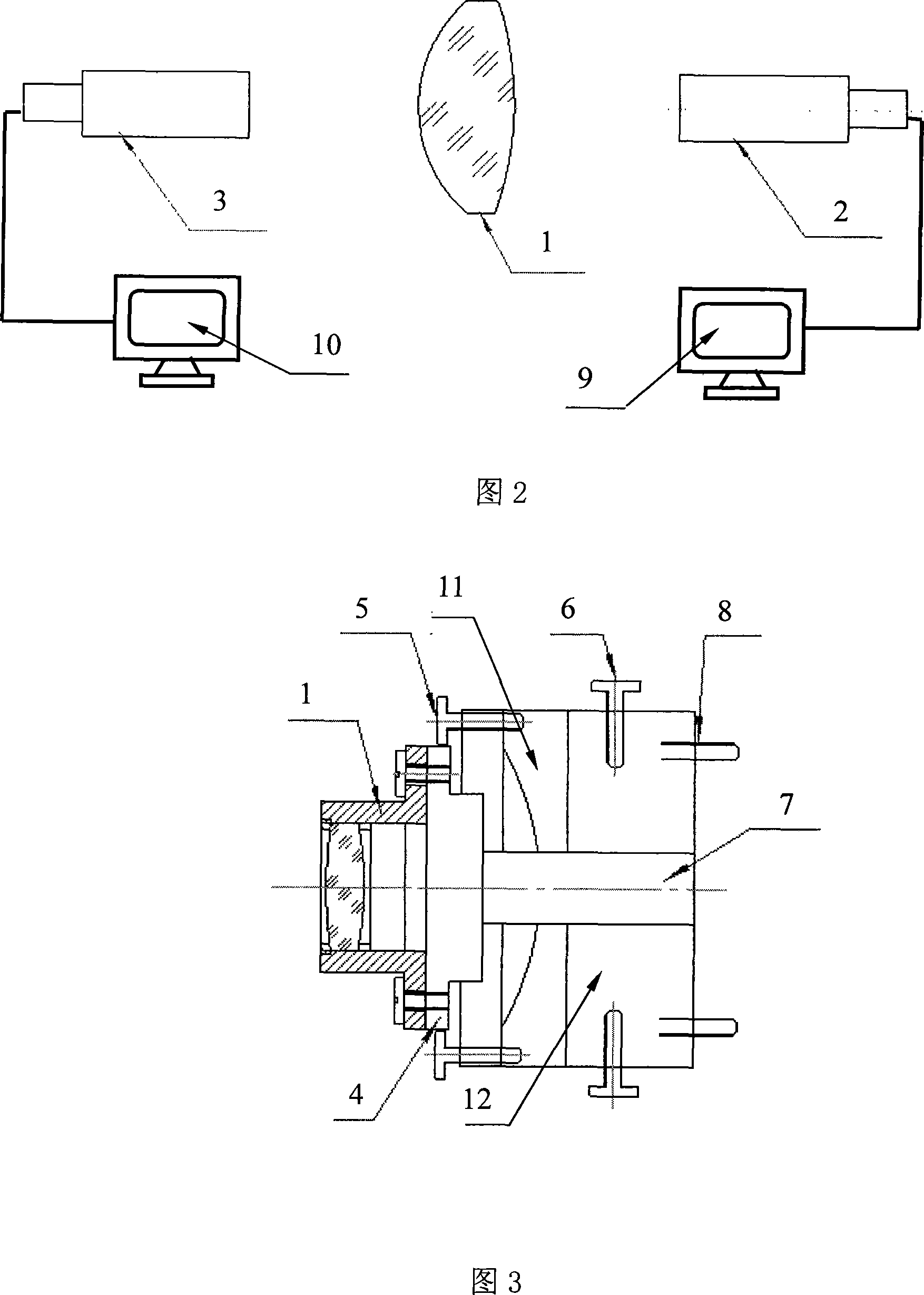

[0025] The processing flow chart of the present invention is shown in Fig. 1, comprises the following steps: install a second centering instrument 3 on the lathe main shaft left side, install a first centering instrument 2 on the lathe tailstock, adjust the second centering instrument 3 and the first Make sure that the desired objects 2 are opposite to each other; install the tooling chuck on the lathe spindle through the lathe spindle connecting screw 8, and fix the infrared optical lens assembly 1 that needs to be optically centered; observe the two balls of the infrared optical lens assembly 1 at the same time Center deviation is adjusted by the main tuner according to the observation information (repeated adjustment is required), and the relative axis of the two ball centers meets the coaxial design requirements; according to the technical requirements mentioned in the drawings, precision machining is carried out to semi-finished products. When adjusting the eccentricity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com