Micro-plasma arc welding gun

A plasma arc and welding torch technology, which is applied in the field of arc welding equipment, can solve the problems of base metal collapse, increase the workload of plastic processing, and large diffusion angle, etc., and achieve the effects of reducing heat conduction stroke, improving cooling effect, and high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

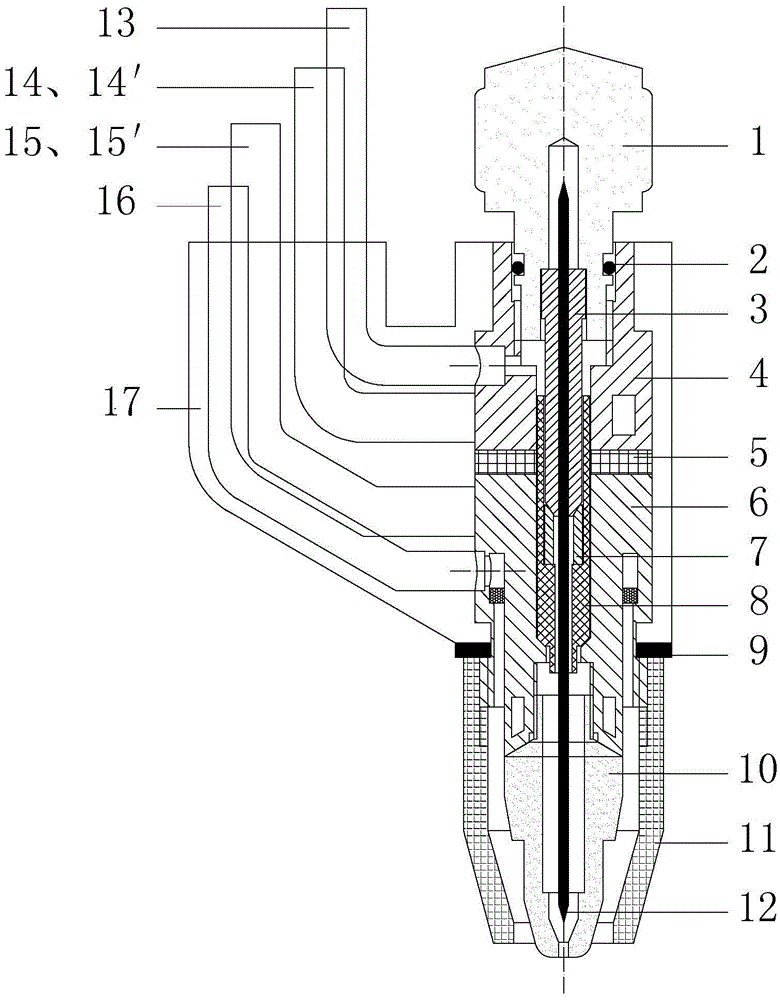

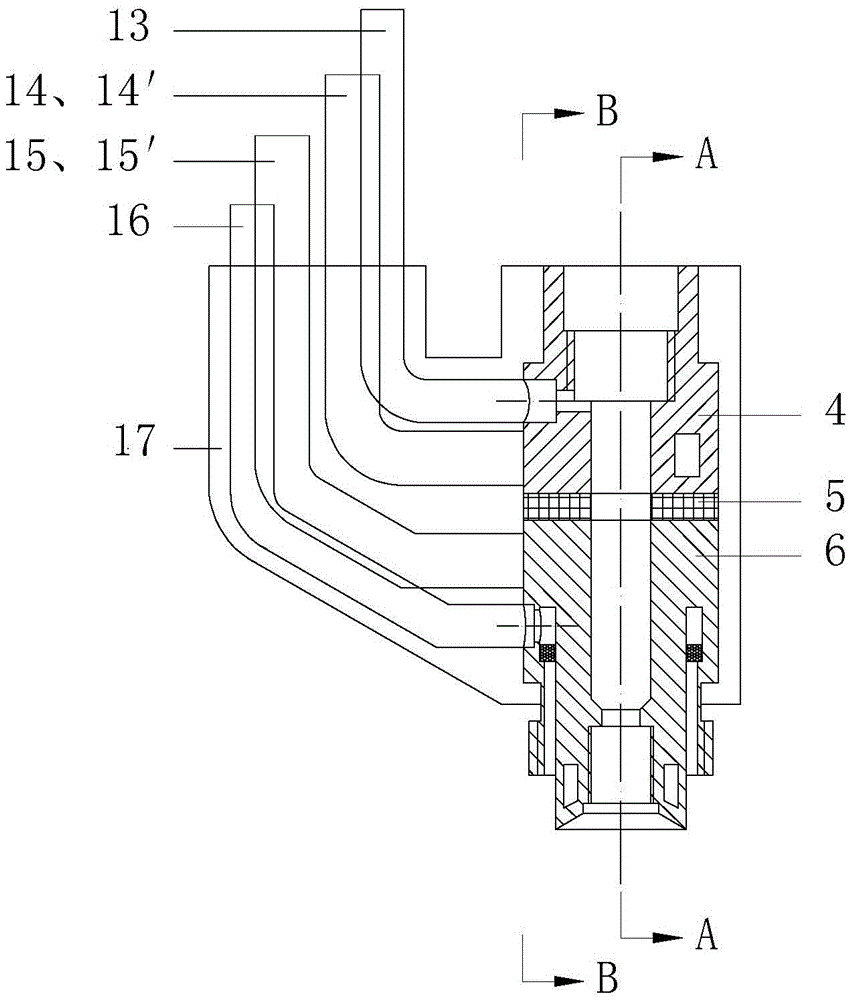

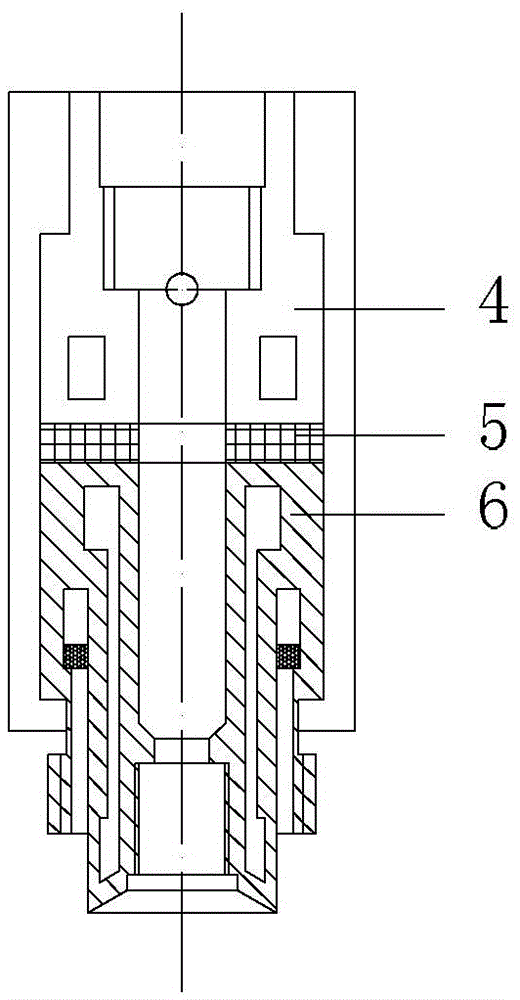

[0034] The micro-beam plasma arc welding torch provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] like figure 1- As shown in Figure 8, the micro-beam plasma arc welding torch provided by the present invention includes: tungsten indenter 1, sealing ring 2, tungsten clamp 3, upper gun body 4, insulator 5, lower gun body 6, centering top column 7 , centering sleeve 8, gun mouth 10, shielding gas cap 11, tungsten pole 12 and handle 17; Wherein upper gun body 4 is made up of upper gun body body 4-1 and upper gun body body 4-2, upper gun body body 4-1 is cylindrical, with a central hole at the center of the axis, and the outer diameter of the middle and upper parts is greater than that of the lower part; the outer body 4-2 of the upper gun body is ring-shaped, and is sleeved on the middle and lower parts of the inner body 4-1 of the upper gun Externally, a C-shaped upper gun body cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com