Auxiliary remover for rivet with head

A headed rivet and rivet technology, applied in the field of headed rivet auxiliary remover, can solve the problems of reduced fatigue capacity, aircraft skin damage, low disassembly efficiency, etc., to reduce the problem of oblique drilling, easy quality assurance, and reduced dismantling. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

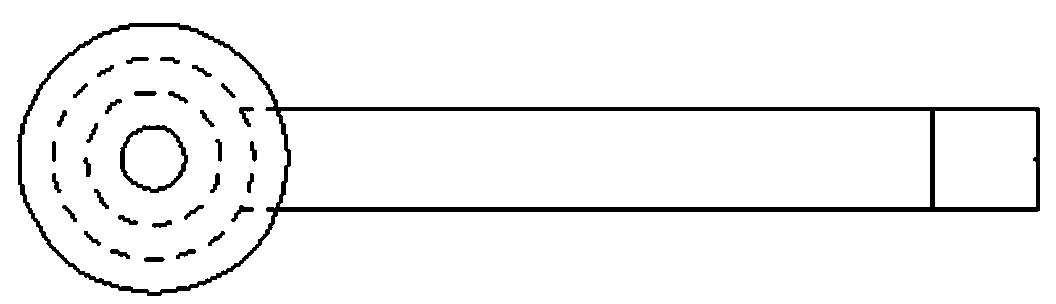

[0031] A headed rivet generally refers to a rivet with a rivet head, its shape is regulated, and its coaxiality with the rivet shaft is very high. The amount of round head rivets used on aircraft is very large, and a large number of hollow rivets are also used. From a wide-area perspective, the half-round head rivet is relatively the most widely used rivet at present.

[0032] Such as Figure 4 The shown rivet head 7 is a typical half-round head rivet head structure, and the other end of the corresponding rivet is the forming head of an automatic rivet machine, and the shape is not very consistent. Therefore, the removal is based on the removal of the rivet head 7 .

[0033] The nominal diameter of the rivet head 7 is greater than that of the rivet rod, so the diameter of the hole drilled by the drill bit is slightly smaller than or equal to the nominal diameter of the rivet rod.

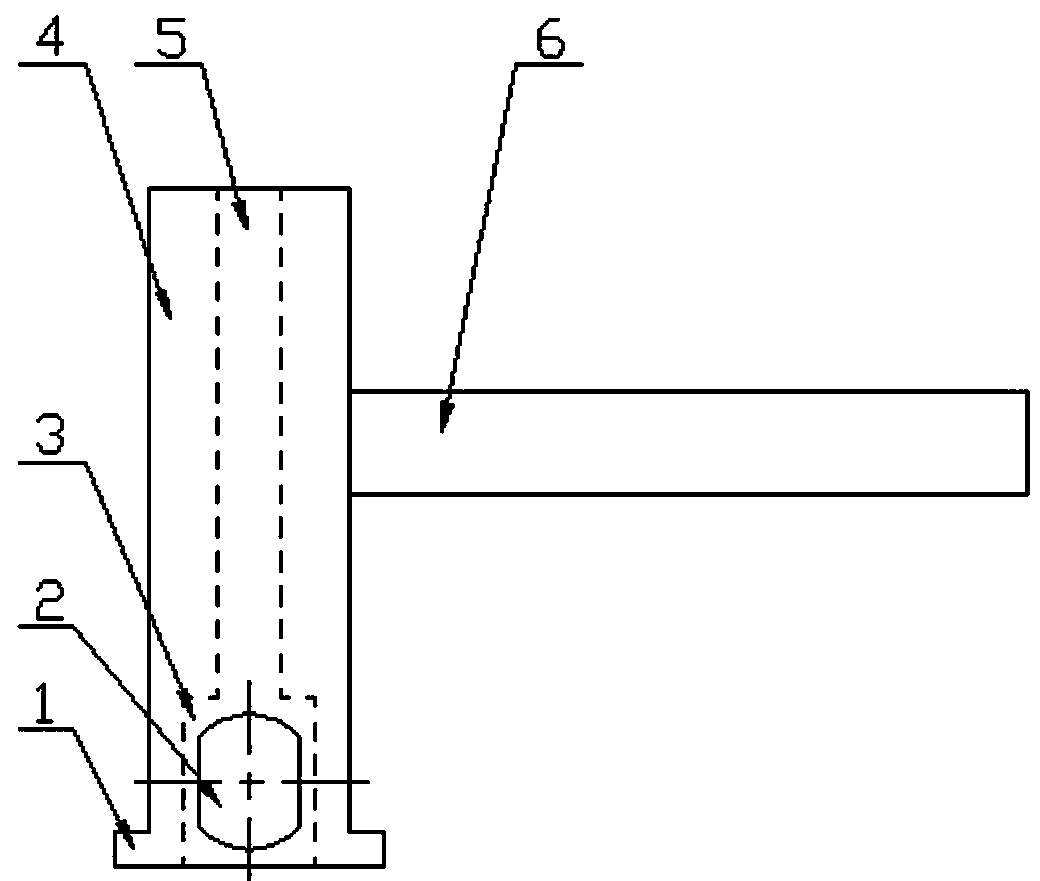

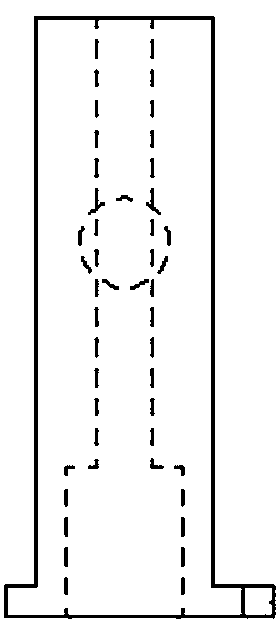

[0034] In view of this, refer to the attached figure 1 And attached figure 2 , a head rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com