Harmonic reducer with lubricating function

A harmonic reducer, functional technology, applied in the direction of gear lubrication/cooling, control of mechanical energy, casing/cover/support, etc. The effect of ensuring normal meshing and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

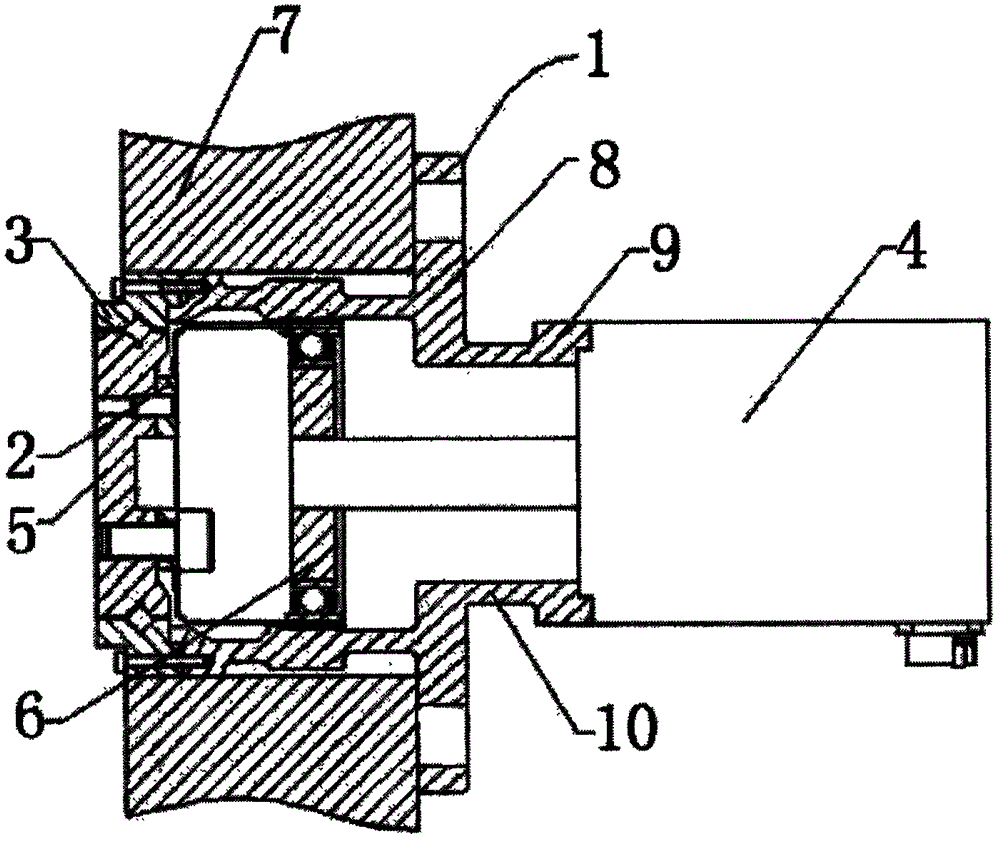

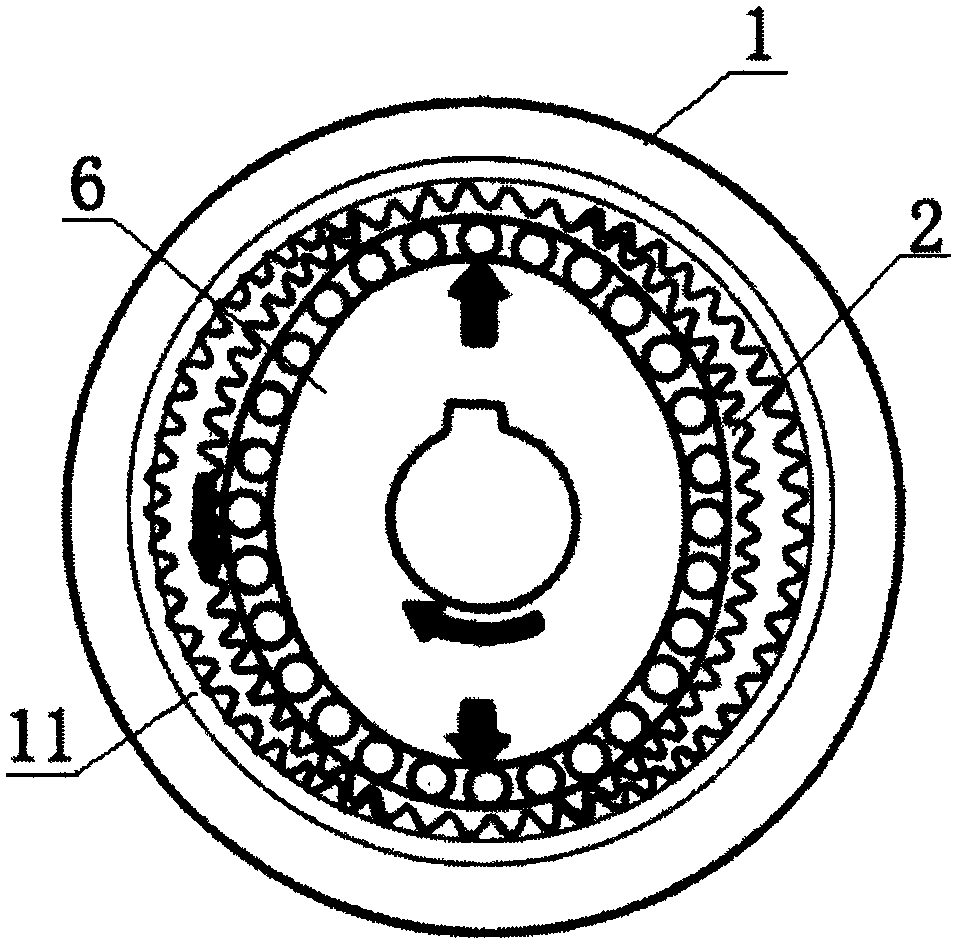

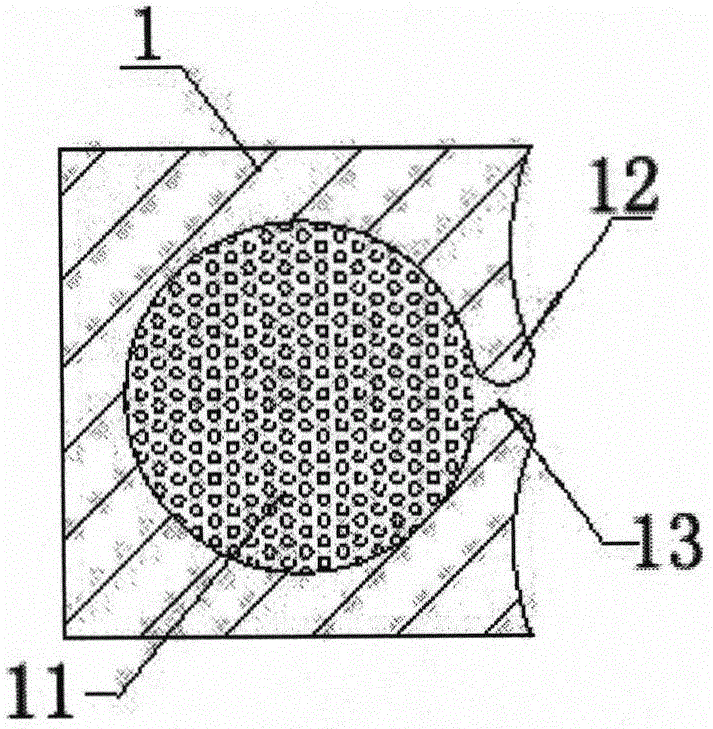

[0016] Such as figure 1 , figure 2 As shown, a harmonic reducer with a lubricating function includes a rigid wheel 1, and a flexible wheel 2 is connected to the rigid wheel 1. One end of the rigid wheel 1 is fixedly connected to a bearing holder 3, and the other end is connected to a servo motor 4. One side of the rigid wheel 1 is provided with a reducer fixing seat 7, and the bearing fixed frame 3 is connected with an output flange 5 for rotation, and the output flange 5 is fixedly connected with the flexible wheel 2, and the bearing fixed frame 3 is connected to the output method through the cross roller bearing. Lan 5 is connected to the drive, and the flexible wheel 2 is connected with a harmonic generator 6 for rotation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com