Independent arm wheel type movement mechanism of tunnel cable inspection robot

A technology for inspection robots and tunnel cables, which is applied in motor vehicles, manipulators, transportation and packaging, etc. It can solve problems such as short circuits and dangers of wires, and achieve the effects of increasing static friction, increasing stability, and improving stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides a one-armed wheeled motion mechanism of a tunnel cable inspection robot. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

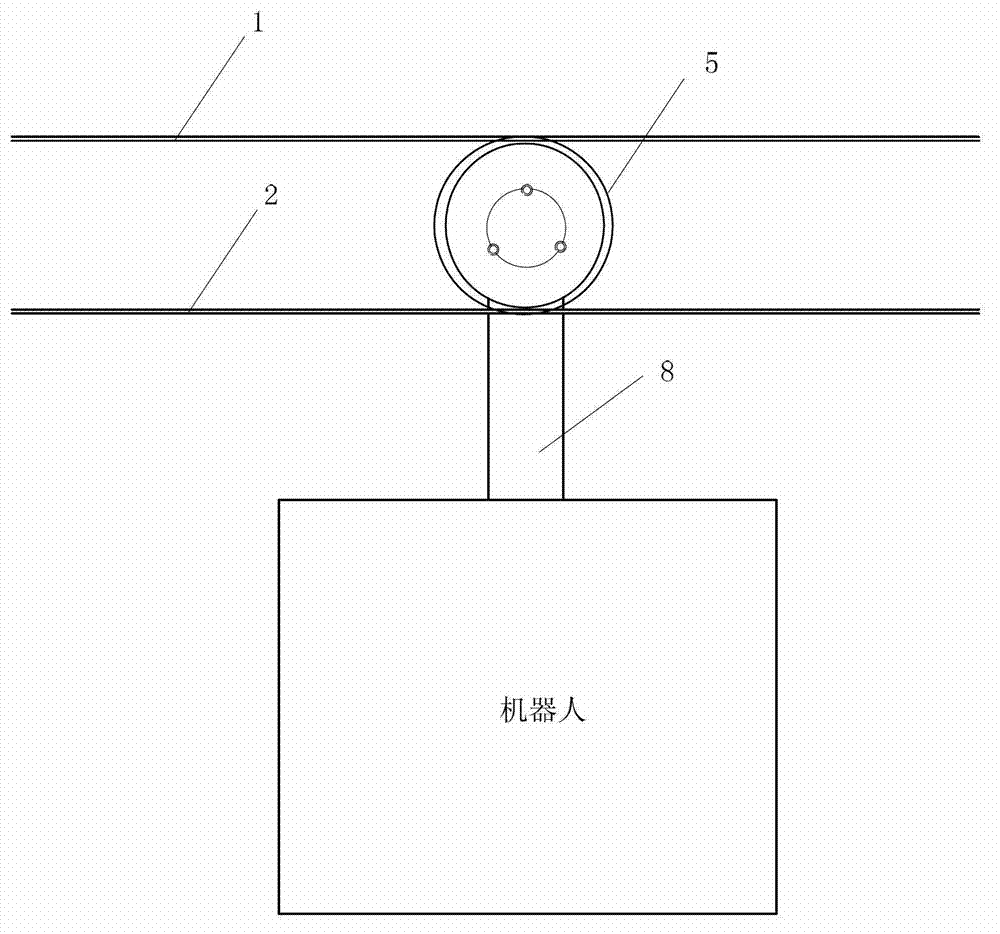

[0033] figure 1 It is a schematic diagram of the motion mechanism and track including the tunnel cable inspection robot, in which the one-armed wheel mechanism and the motor part constitute the head part of the robot, and the wheels are clamped between the upper track 1 and the lower track 2 for movement. The main body part is connected by groove type connecting arm 8.

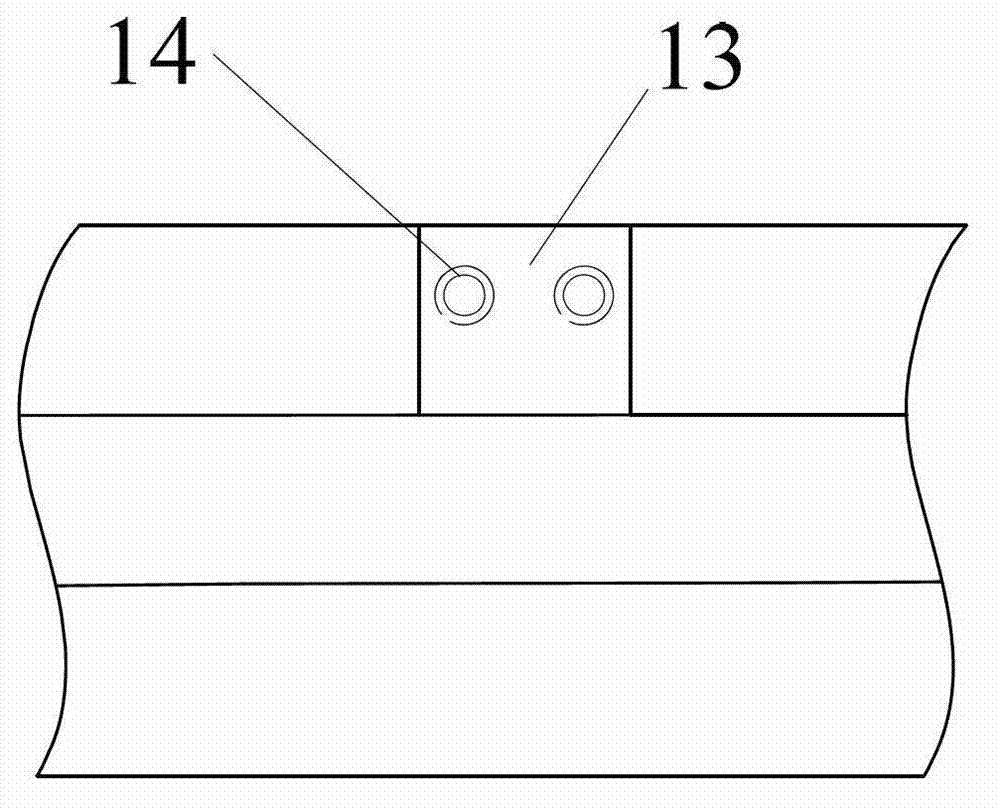

[0034] Figure 2 is the front view and cross-sectional view of the track: due to the limited weight of the robot, light aluminum profiles are used as the material of the guide rail, which reduces the burden of installation and transportation while ensuring the mechanical strength. Considering the smooth operation of the robot, the gap left by the wheel 5 after sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com