Turning chatter suppression device based on piezoelectric ceramic driver

A piezoelectric ceramic driving and suppressing device technology, which is applied in the direction of automatic control devices, turning equipment, feeding devices, etc., can solve the problems of the limitation of the vibration absorption effect of the passive vibration absorber and the continuous change of the natural frequency, and achieve good turning effect and response The effect of fast speed and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

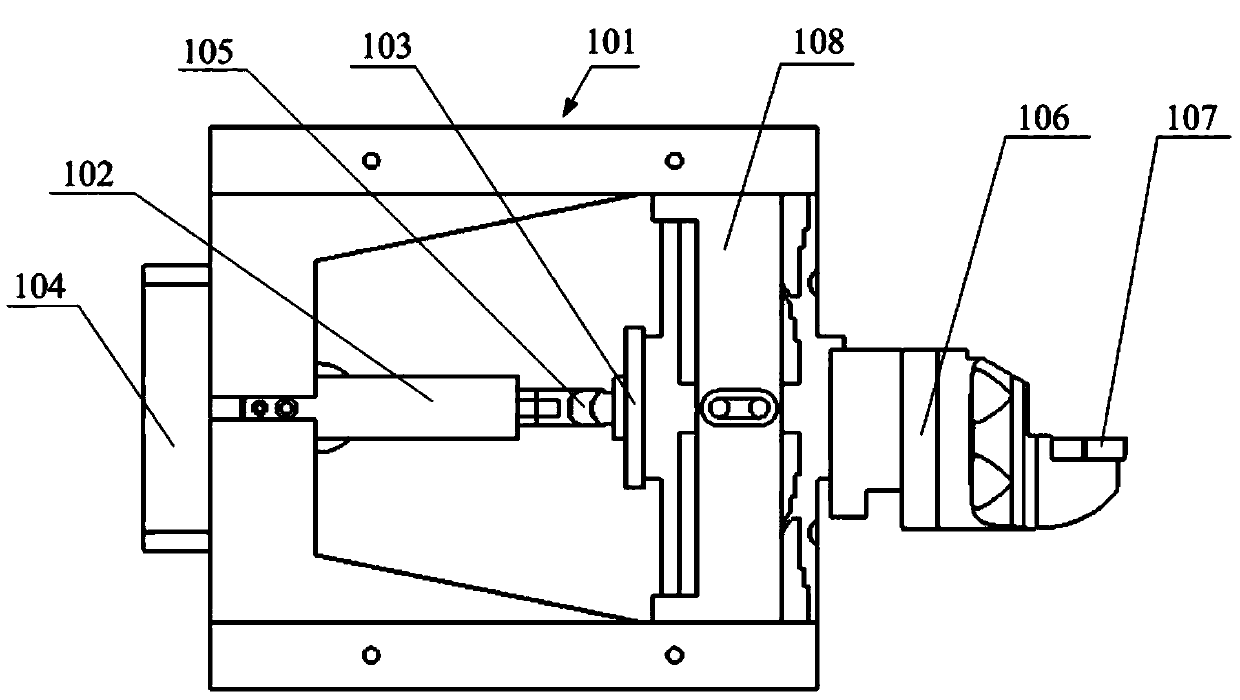

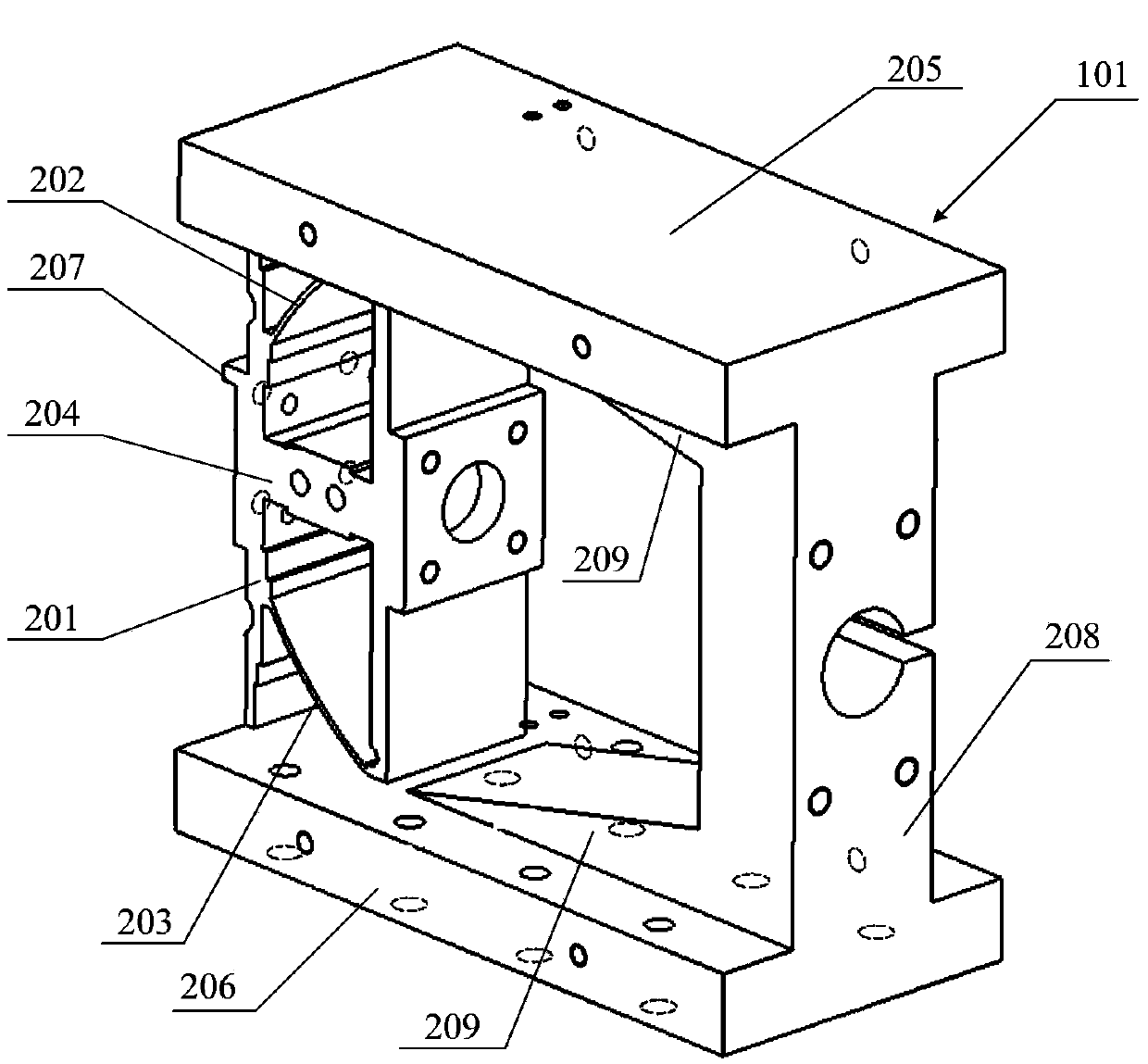

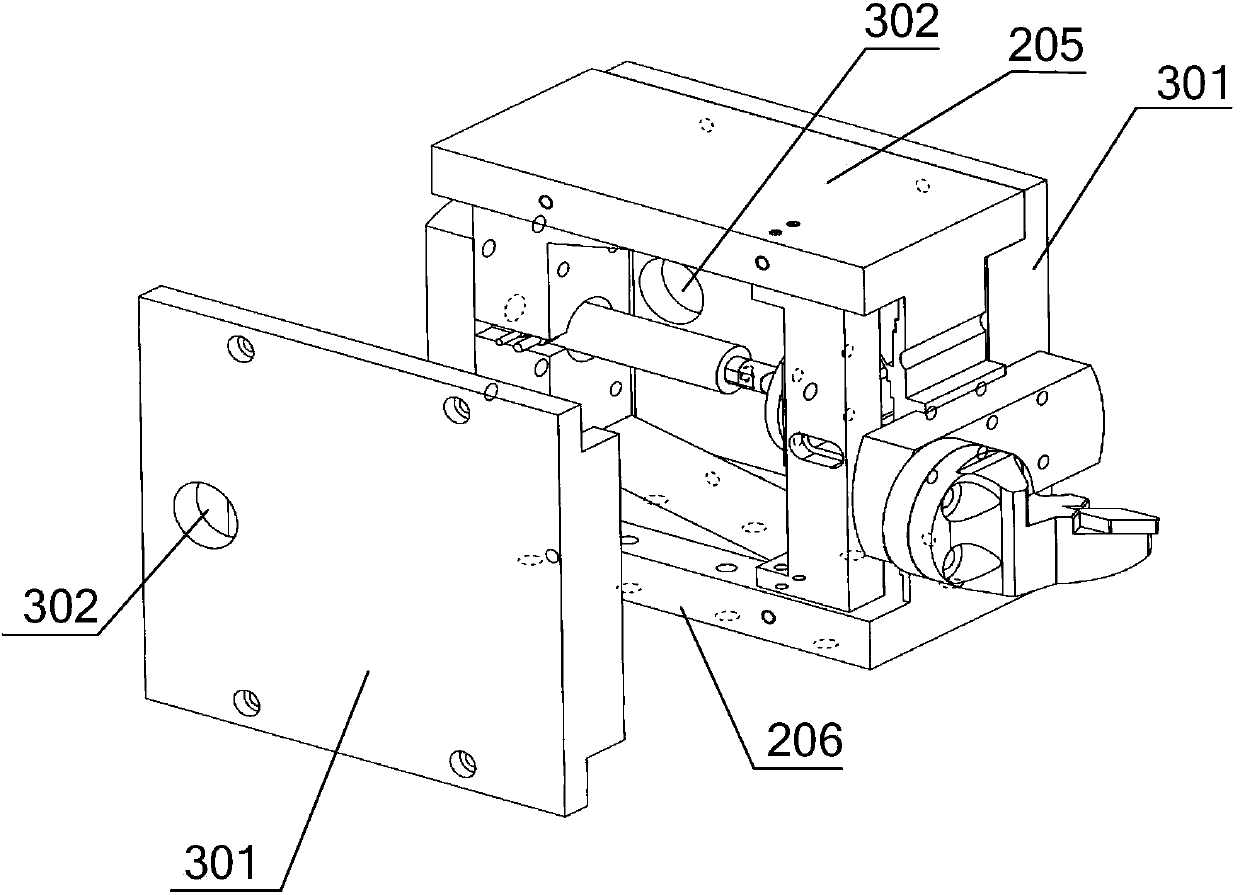

[0030] Such as figure 1 As shown, a turning chatter suppression device based on piezoelectric ceramic drive, including a tool holder 101, a piezoelectric ceramic driver 102, a front flange 103, a rear flange 104, a flexible connector 105, and a tool adapter 106, cutter 107, vibration sensor and controller. Wherein, the tool holder 101 includes a peripheral frame. The front end of the piezoelectric ceramic driver 102 is connected to the rear end of the front flange 103 through a flexible connector 105, and the front end of the front flange 103 is fixedly connected to the front end of the tool holder 101; the rear end of the piezoelectric ceramic driver 102 passes through The rear flange 104 is fixedly connected to the rear end of the tool holder 101 .

[0031] The front flange 103 is also provided with a first positioning hollow cylindrical sleeve, the front end cylindrical surface of the first positioning hollow cylindrical sleeve cooperates with the mounting hole at the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com