Concentricity jig of flange mounting hole

A flange mounting and coaxiality technology, applied in the direction of manufacturing tools, workpiece clamping devices, electrical components, etc., can solve the problems of difficult coaxiality, no tools, and a high probability of errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

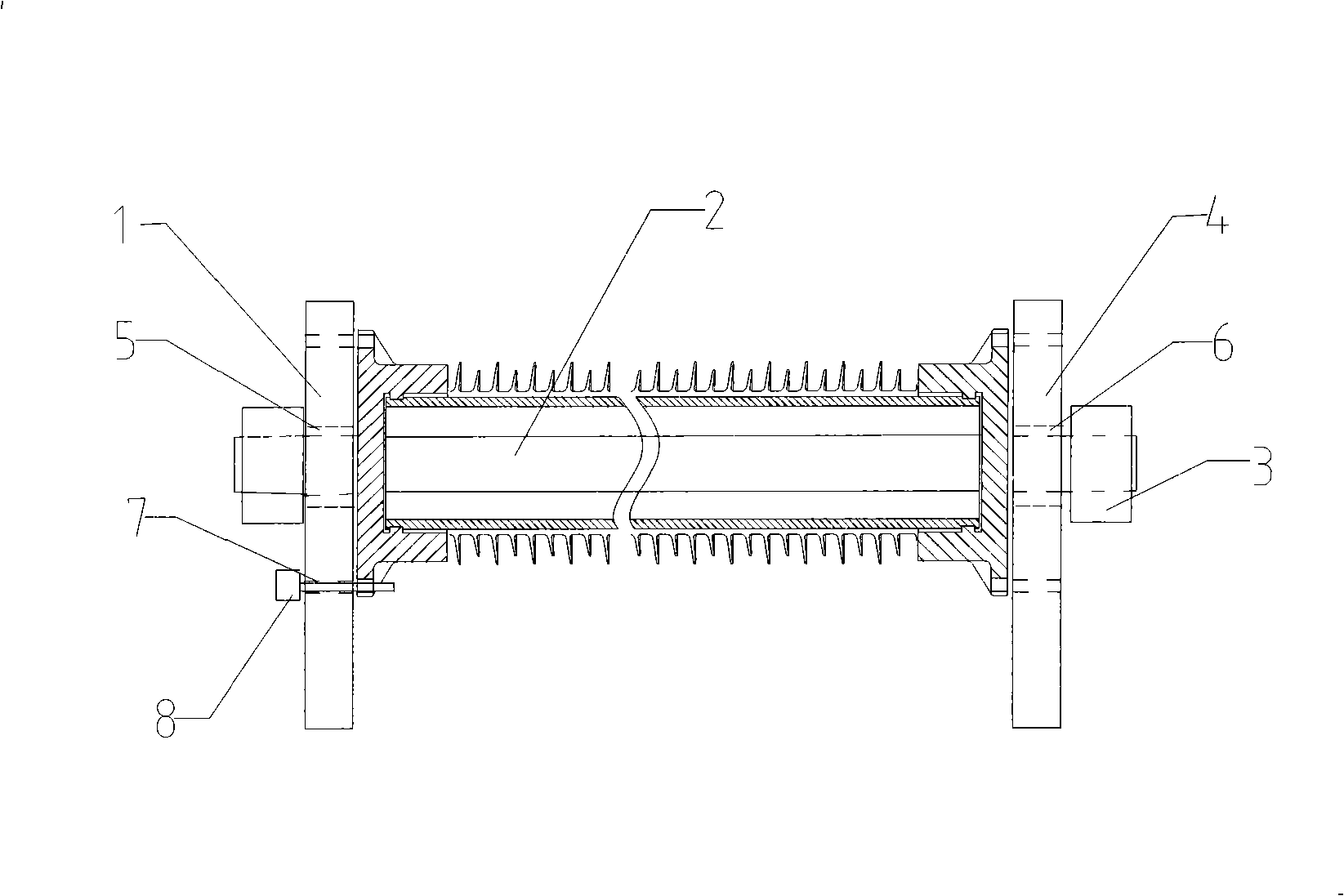

[0008] As shown in the figure, the present invention consists of two pressing plates 1, 4, pull rod 2, and nut 3.

[0009] Two pressure plates 1,4 are identical in shape and structure, both are semicircular, and have holes 5,6 respectively on the same horizontal plane on the two pressure plates 1,4, and pull rod 2 passes through in these holes 5,6.

[0010] Several holes 7 are distributed on the pressure plates 1 and 4, and the positions of the holes 7 are at the same position as the mounting holes of the flange.

[0011] When the flange is glued to the insulator, the pressure plates 1 and 4 are respectively pressed on the outside of the two flanges, the holes 7 on the pressure plates 1 and 4 are bolted to the corresponding flange mounting holes with bolts 8, and then the pull rod 2 is used to pass through the insulator Fasten with nuts 3 on the outside of the pressure plates 1 and 4 to ensure that the two pressure plates 1 and 4 are coaxial. In this way, through the coaxialit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com