Machining method for improving coaxiality accuracy of opposite holes of part

A processing method and coaxiality technology, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problem that the comprehensive error cannot meet the processing needs, the hole error of the other side is processed, and two holes cannot be bored on one side. Holes and other problems, to achieve the effect of simple and convenient processing method, improve processing accuracy, and improve processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

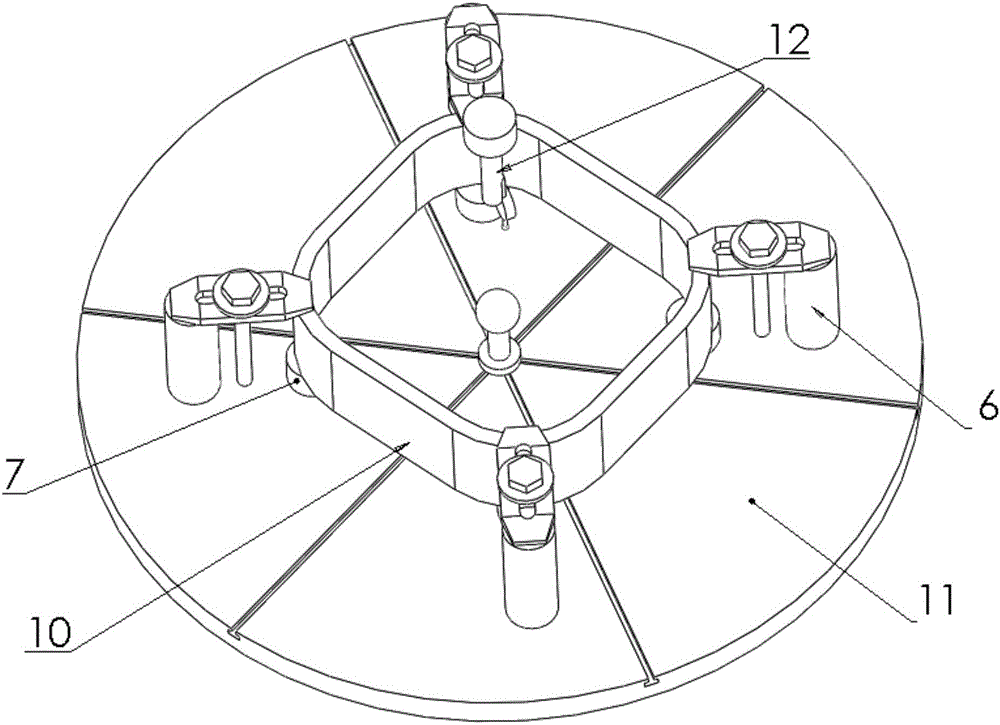

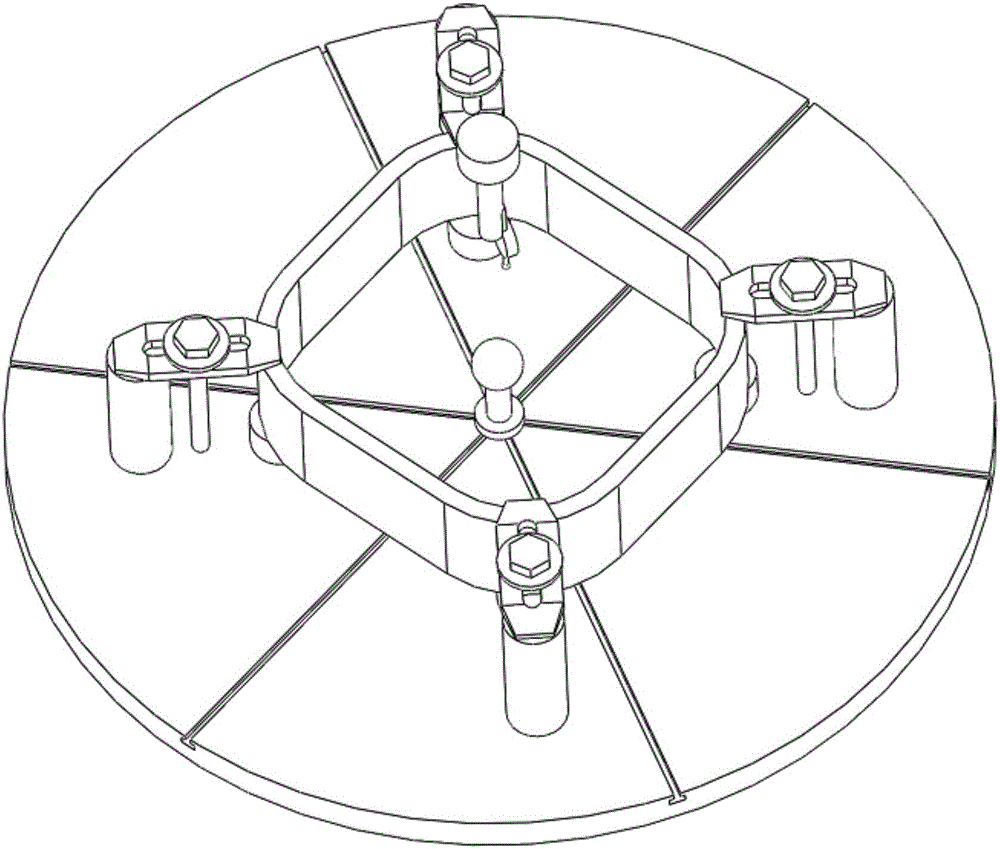

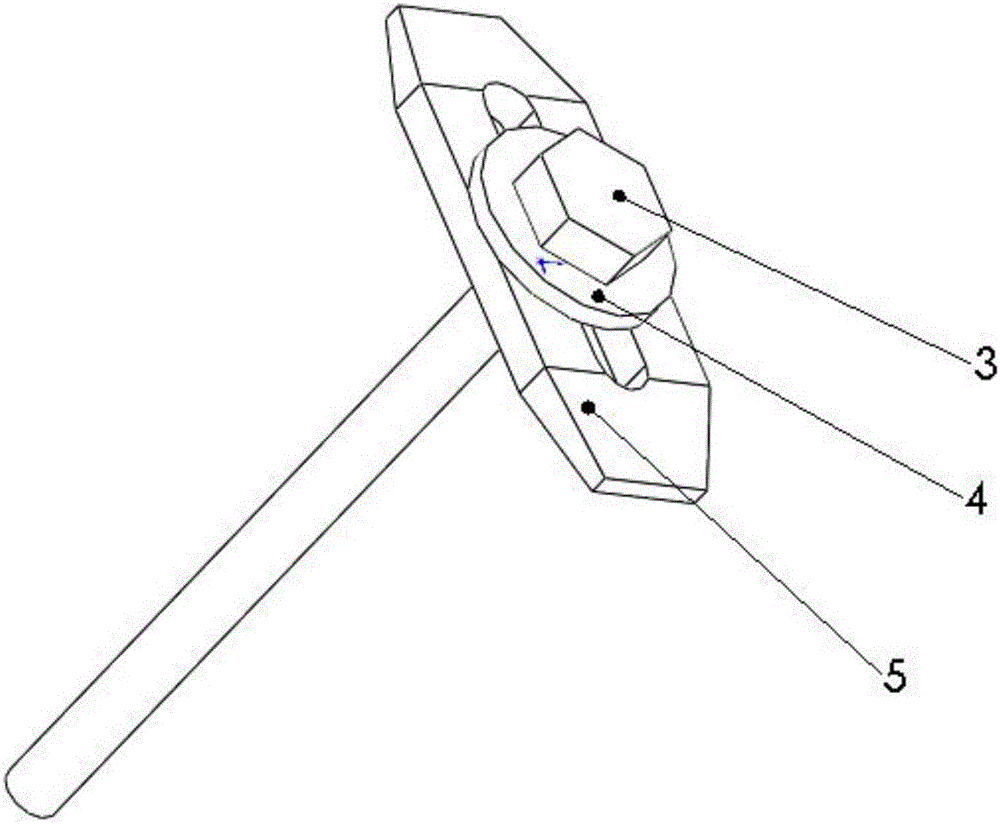

[0051] Such as figure 1 , 2 As shown, in the present embodiment, the part 10 to be processed is a frame structure, and the pressing plate assembly, the equal height block 6 and the spacer 7 are four, and the materials of the equal height block 6 and the spacer 7 are all chrome-manganese steel, and the calibration assembly The material is quenched stainless steel.

[0052] The four pads 7 are located symmetrically on the workbench 11, the positions of the four platen assemblies and the four equal-height blocks 6 correspond to the positions of the four pads 7, and they are symmetrically located on the workbench 11, wherein the height of the pads 7 is 150mm, The height of the equal height block 6 is 242mm, the height of the calibration assembly is 310mm, the height of the part 10 to be processed is 92mm, and a circular hole is respectively processed on the four side walls of the part 10 to be processed.

[0053] The processing accuracy of the parts in this embodiment is improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com