Clamping and cooling device for manual sharpening of external turning tool

A technology of an external turning tool and a cooling device, which is applied to grinding/polishing safety devices, accessories of tool holders, tools used in lathes, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

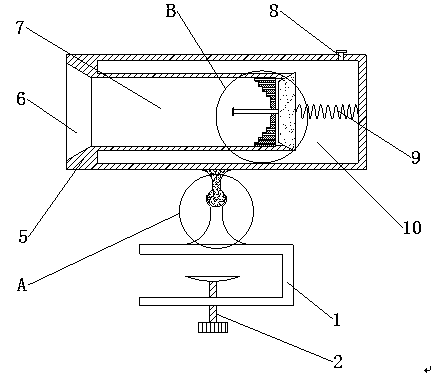

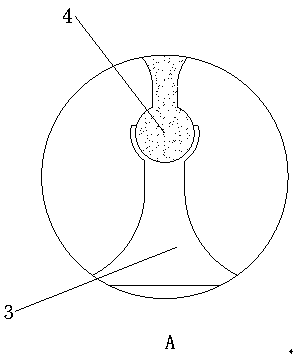

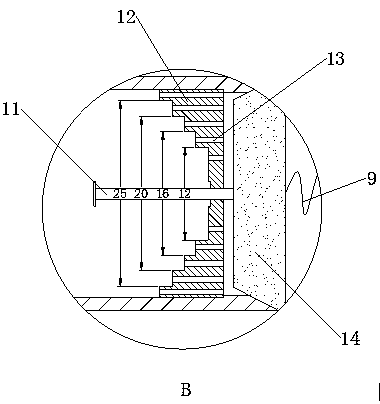

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The present invention provides a clamping and cooling device for manually sharpening outer turning tools, which includes a U-shaped clamp 1, a clamping bolt 2, a supporting column 3, a connecting column 4, a clamping sleeve 5, an opening 6, a cavity 7, Filling port 8, spring 9, liquid storage chamber 10, push rod 11, fixing seat 12, through hole 13, sealing plug 14, outer circle turning tool 15, fixing ring 16, clamping block 1601, elastic layer 1602, clamping Hole 1603, the lower end of U-shaped clamp 1 is threadedly connected with clamping bolt 2, the top of U-shaped clamp 1 is fixedly connected with support column 3, the top of support column 3 is rotatably connected with connecting column 4, and the top of connecting column 4 is fixedly connected with The clamping sleeve 5 is provided with a cavity 7 and a liquid storage chamber 10 inside the clamping sleeve 5. One end of the cavity 7 is provided with an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com