Automatic knife sharpening device and automatic knife sharpening system

A technology for automatic knife sharpening and knife sharpening, which is applied in the direction of grinding automatic control device, grinding drive device, grinding machine parts, etc., to achieve the effect of uniform degree, low energy consumption and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

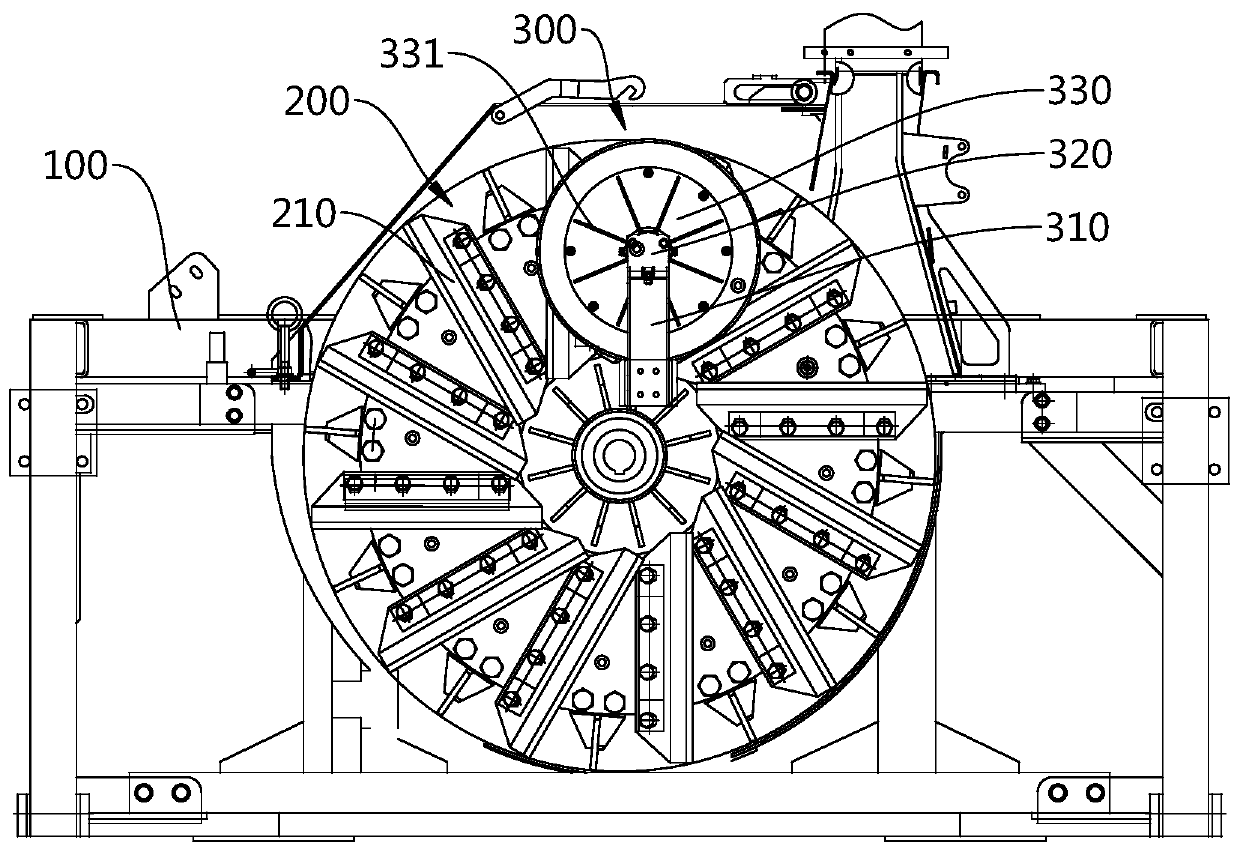

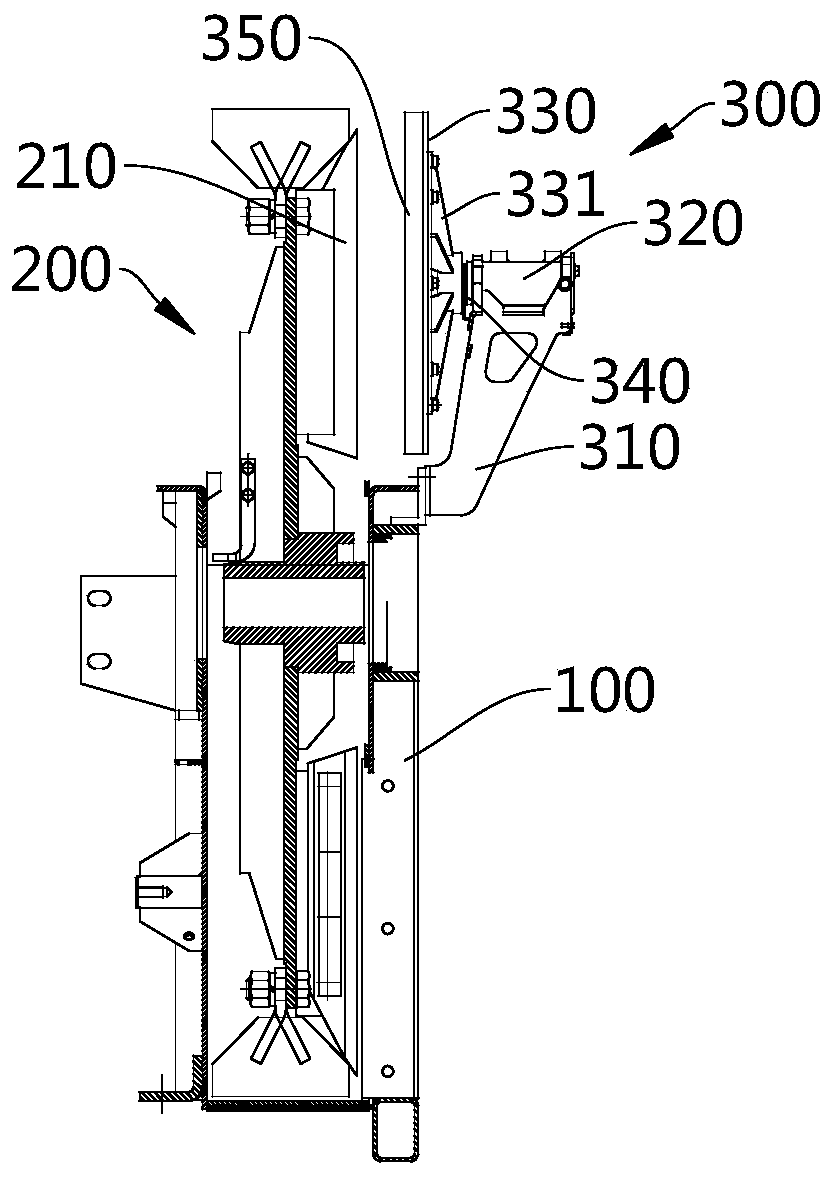

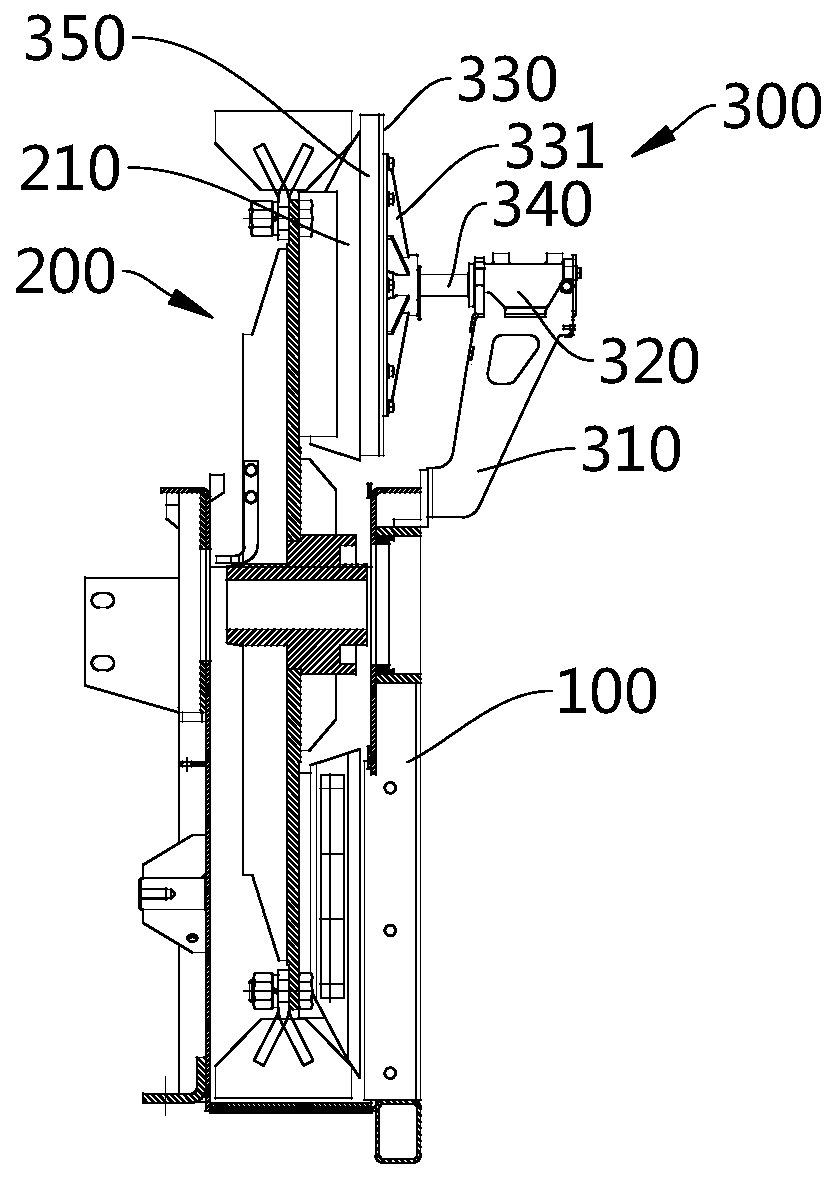

[0038] When the silage harvester harvests silage such as corn stalks, it will use the wheel cutter 200 chopper to chop it. After the silage harvester has been working for a period of time, the moving blade 210 of the wheel cutter 200 will wear to a certain extent, and the moving The sharpness of the blade 210 directly affects the chopping quality of the silage, and when the movable blade 210 is not sharp, the energy consumption of the wheel cutter 200 shredder is relatively high. In order to keep the moving blades 210 of the wheel cutter 200 sharp, the worn moving blades 210 are often disassembled one by one, manually sharpened one by one and then installed back. The existing sharpening method is inefficient, and the degree of grinding of each movable blade 210 on the wheel cutter 200 may be inconsistent, which may cause more or less grinding of individual movable blades 210, and the cutting edges are not on the same working plane, and some movable blades 210 The chopping work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com