Automatic blade sharpening device with continuous guidable sharpening track and sharpening method

A blade and sharpening technology, which is applied in the direction of grinding frame, grinding bed, grinding slide, etc., can solve the problems of non-standard cutting edge size, unusable production line, serious physical injury, etc., and achieve high sharpening efficiency , Efficiency improvement, and the effect of high sharpening precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

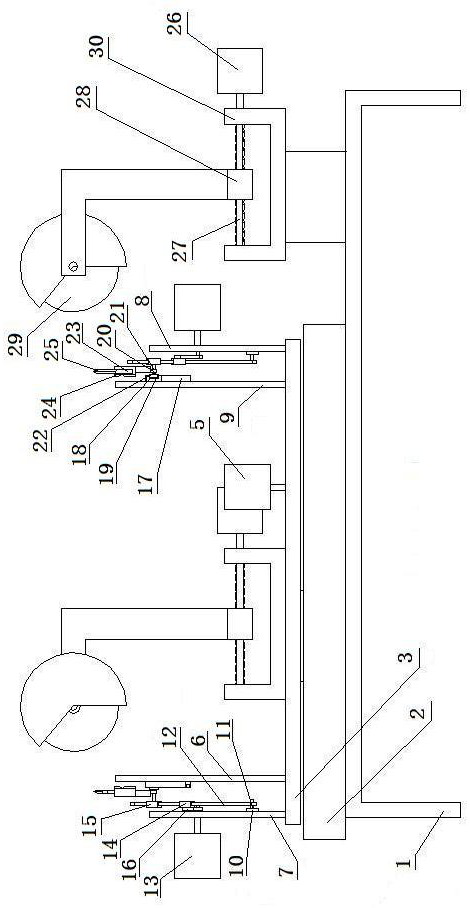

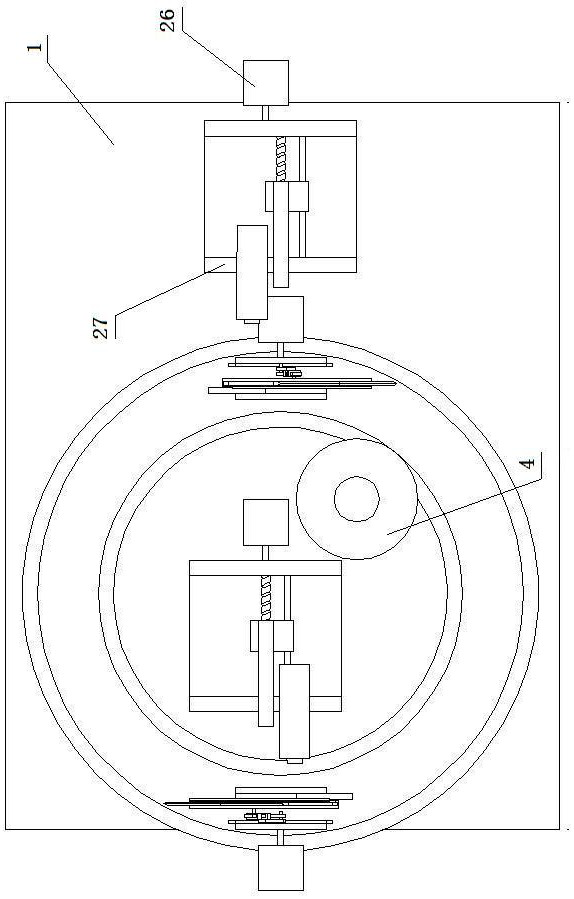

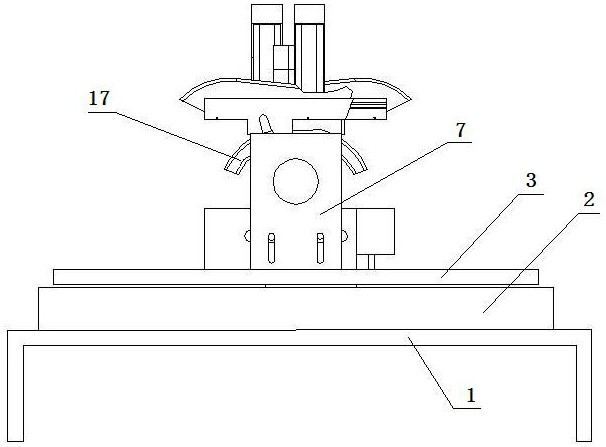

[0032] An automatic blade sharpening device with a continuous guide sharpening track, which consists of: a base frame 1, the upper plane of the base frame has 2 cylindrical protrusions, and are respectively installed on the cylindrical protrusions There is a grinding wheel device, a rotating platform frame 2 is installed on the base frame, and a rotating platform 3 is installed on the rotating platform frame, which can rotate around the rotating platform frame along the Z axis. The inner ring of the rotating platform is connected to the The gear 4 is engaged, and the upper plane of the rotating platform is fixed with the outer vertical plate A7, the inner vertical plate A6, the inner vertical plate B9, the outer vertical plate B8, the outer vertical plate A, and the outer vertical plate B. A crank slider device is respectively installed, and its main purpose is to provide power and realize the size of the crank at two limit positions, which can also be realized by a crank rocke...

Embodiment 2

[0035] According to the automatic blade sharpening device with a continuous guide sharpening track described in Embodiment 1, the crank slider device includes an adjustment piece 10, and the adjustment piece is installed under the outer vertical plate A, which can Move up and down along the Z axis for adjustment, and connect with the rocker 12 through the rotating shaft 11, wherein the rocking rod can only rotate along the rotating shaft A, and the motor A13 is installed on the outer vertical plate A and is connected to the crank 16 through the connecting shaft. One end is connected, and the other end of the crank is connected with the slider A14 through a rotating shaft to realize mutual rotation. The slider A and the slider B15 are respectively sleeved on the rocker and move linearly relative to the rocker.

Embodiment 3

[0037]According to the automatic blade sharpening device with a continuous guide sharpening track described in Embodiment 1, the sharpening track groove device includes a track groove 17, and the track groove is fixed on the inner vertical plate A, and the Guide wheel A18, guide wheel B19 are respectively installed in the track groove, can roll along the track of groove, described guide wheel A, described guide wheel B, guide block 20 are connected by rotating shaft B 22, described guide block It is connected with the rotating shaft A21 and can rotate around the rotating shaft A, and the rotating shaft A is fixed on the sliding block B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com