Coating technology of water-based coating for thick steel plate

A coating process, water-based paint technology, applied in the direction of surface coating liquid devices, coatings, pre-treated surfaces, etc., can solve the problems of inapplicability, and achieve the effects of cost saving, pollution reduction, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

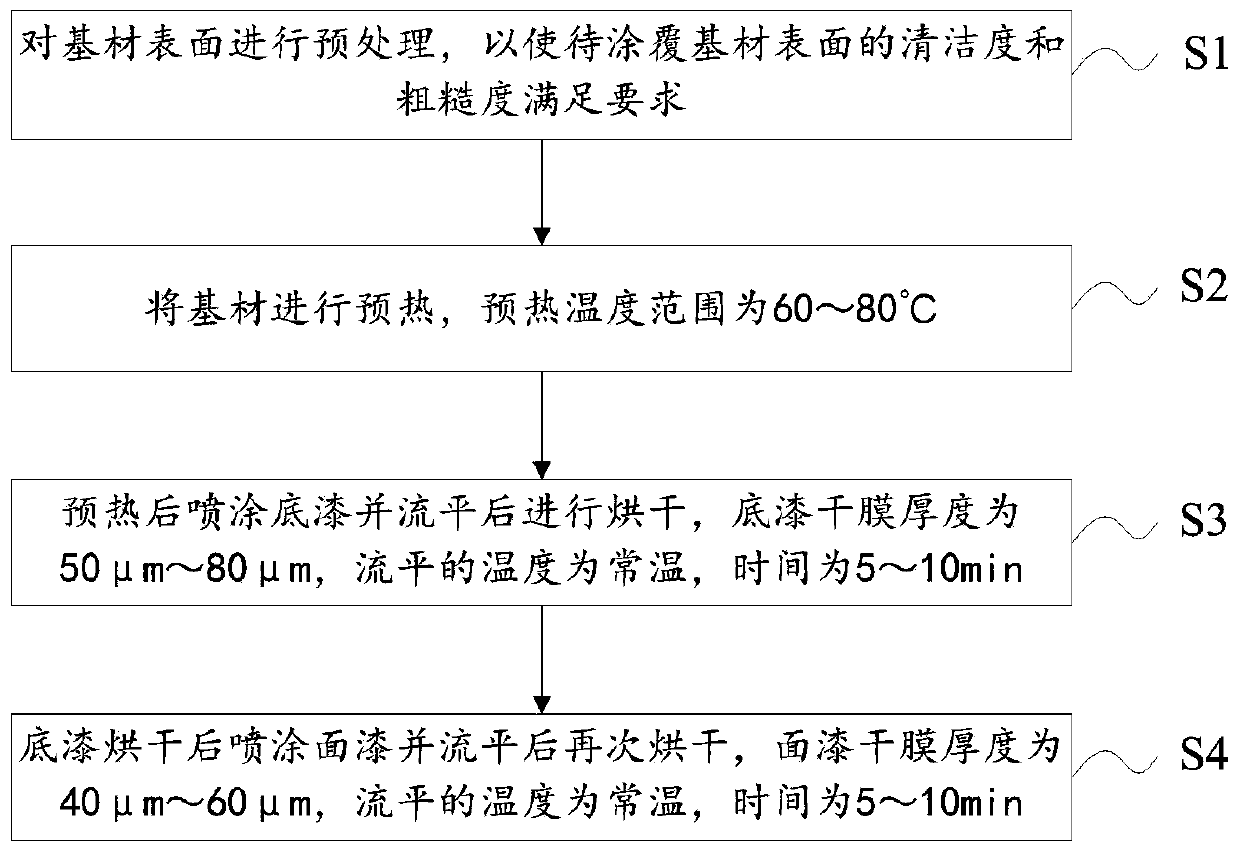

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the water-based coating process of thick steel plate comprises the following steps:

[0043] S11: Perform mechanical surface treatment on the substrate and clean it with a solvent to remove dust, oil, rust, scale, water-soluble salt, welding residue, flash and burrs on the surface of the substrate.

[0044] S12: Preheat at 60-80°C for 30 minutes.

[0045] S13: Under the condition that the construction environment temperature is 10°C and the relative humidity is 85%, spray the primer on the pretreated substrate, the spraying method is air spraying, the diameter of the spray gun is 2.0mm, and the distance between the nozzle of the spray gun and the substrate 300mm, span 1 / 3, gun speed 500mm / s, gun pressure 0.35MPa. Leveling for 5 minutes after spraying, and then drying at 60°C for 45 minutes, with a dry film thickness of 50 μm.

[0046] S13: Spray the topcoat after the primer paint film is dry. The spraying method is air spraying. The diameter of the...

Embodiment 2

[0048] In this embodiment, the water-based coating process of thick steel plate comprises the following steps:

[0049] S21: Perform mechanical surface treatment on the substrate and clean it with a solvent to remove dust, oil, rust, scale, water-soluble salt, welding residue, flash and burrs on the surface of the substrate.

[0050] S22: Preheat at 60-80°C for 30 minutes.

[0051] S23: Under the condition that the construction environment temperature is 40°C and the relative humidity is 50%, spray the primer on the pretreated substrate, the spraying method is air spraying, the diameter of the spray gun is 2.0mm, and the distance between the nozzle of the spray gun and the substrate 200mm, span 1 / 2, gun speed 300mm / s, gun pressure 0.55MPa. The surface paint film was leveled for 10 minutes after spraying, and then dried at 80°C for 30 minutes, and the dry film thickness was 80 μm.

[0052] S24: Spray the topcoat after the primer paint film is dry. The spraying method is air s...

Embodiment 3

[0054] In this embodiment, the water-based coating process of thick steel plate comprises the following steps:

[0055] S31: Perform mechanical surface treatment on the substrate and clean it with a solvent to remove dust, oil, rust, scale, water-soluble salt, welding residues, flash burrs, etc. on the surface of the substrate.

[0056] S32: Preheat at 60-80°C for 30 minutes.

[0057] S33: Under the condition that the construction environment temperature is 10°C and the relative humidity is 85%, spray the primer on the pretreated substrate. The spraying method adopts high-pressure airless spraying, the diameter of the spray gun is 2.5mm, and the distance between the nozzle of the spray gun and the substrate The minimum distance is 300mm, the span is 1 / 3, the gun speed is 500mm / s, and the spray gun pressure is 15MPa. Leveling for 5 minutes after spraying, and then drying at 60°C for 45 minutes, with a dry film thickness of 50 μm.

[0058] S34: Spray the topcoat after the prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com