Two-stage lifting two-tail vehicle with two swinging ends for material piling and taking machine

A two-stage, reclaimer technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of rapid changes in the cylinder lever arm, high energy consumption of ground belt conveyors, and high positions of moving parts, and achieves continuous bulk material transportation. The effect of protecting the working environment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

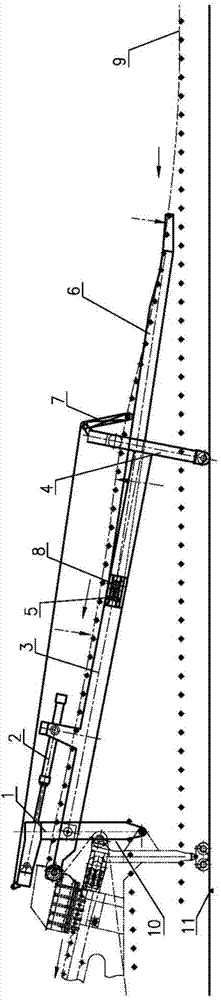

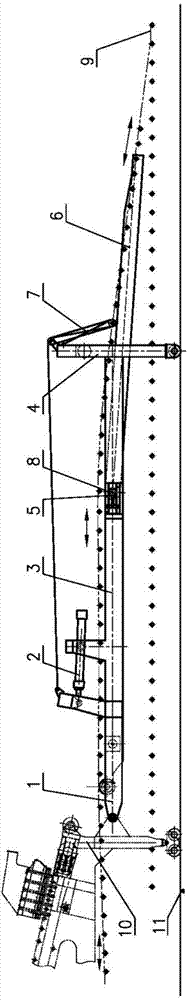

[0011] figure 1 and figure 2 It is a schematic diagram of the stacking state and the straight-through and return reclaiming states of a two-stage lifting two-tailed car with two ends of the stacker and reclaimer swinging at both ends of the present invention.

[0012] The two-stage lifting two-tail car that swings at both ends of this stacker-reclaimer is provided with an L-shaped swing beam 1, and the end of the long arm of the L-shaped swing beam 1 is hinged with the middle part of the main tail car 10 legs to form The middle part of arm is hinged with the middle part of the transverse long arm front end of T-shaped swing tailgate beam 3. The jib end of the L-shaped swing beam 1 is provided with a steering ring 12, and one end of the wire rope 13 is connected with the hydraulic cylinder 2 piston rod ends hinged on the vertical jib of the T-shaped swing tail beam 3 through the steering ring 12. The rear end of the transverse long arm of the T-shaped swing tail beam 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com