Sharpening assembly

A component and grinding wheel technology, which is applied to the parts of grinding machine tools, grinding machines, grinding drives, etc., can solve the problems of reduced tool life, unfavorable on-site installation, and reduced cutting quality, so as to prolong the service life and reduce the cost of equipment. Effect of cost and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

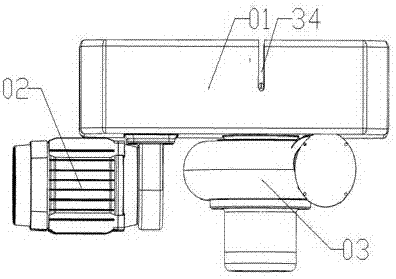

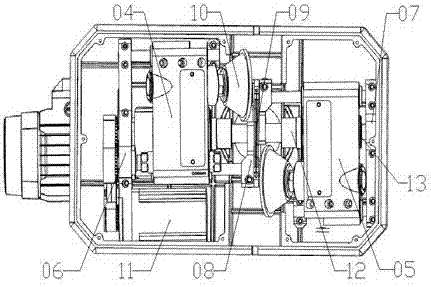

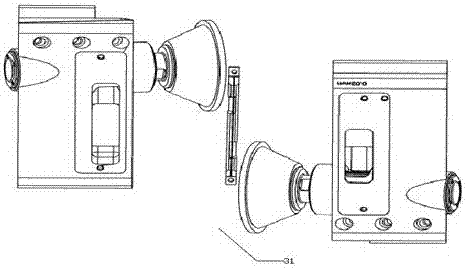

[0024] Refer to attached Figure 1-8 , a sharpening assembly, which includes a sharpening back plate 01, a sharpening mechanism 31, a driving mechanism 32, and an adjustment mechanism 33; the sharpening mechanism 31 includes a left housing 04, a right housing 05, a left housing 04, a right The casing 05 is arranged in the sharpening backboard 01, and is located at both ends of the sharpening backplane 01. The center of the left casing 04 and the right casing 05 is symmetrical, and the left casing 04 and the right casing 05 are respectively provided with a sharpening wheel 10 , a knife sharpening box 09 is arranged between the two knife sharpening wheels 10; knife grooves 34 are arranged on both sides of the knife sharpening back plate 01, and the knife grooves 34 are located at the same horizontal position as the knife sharpening box 09; the drive mechanism 32 includes a driving motor 02, fixedly installed on the sharpening backboard 01, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com