Variable copying tool sharpener

A knife sharpening machine and profiling technology, which is applied in the direction of grinding frame, grinding bed, grinding slide plate, etc., can solve the problems of cumbersome and different production processes, and the curvature of the blade is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

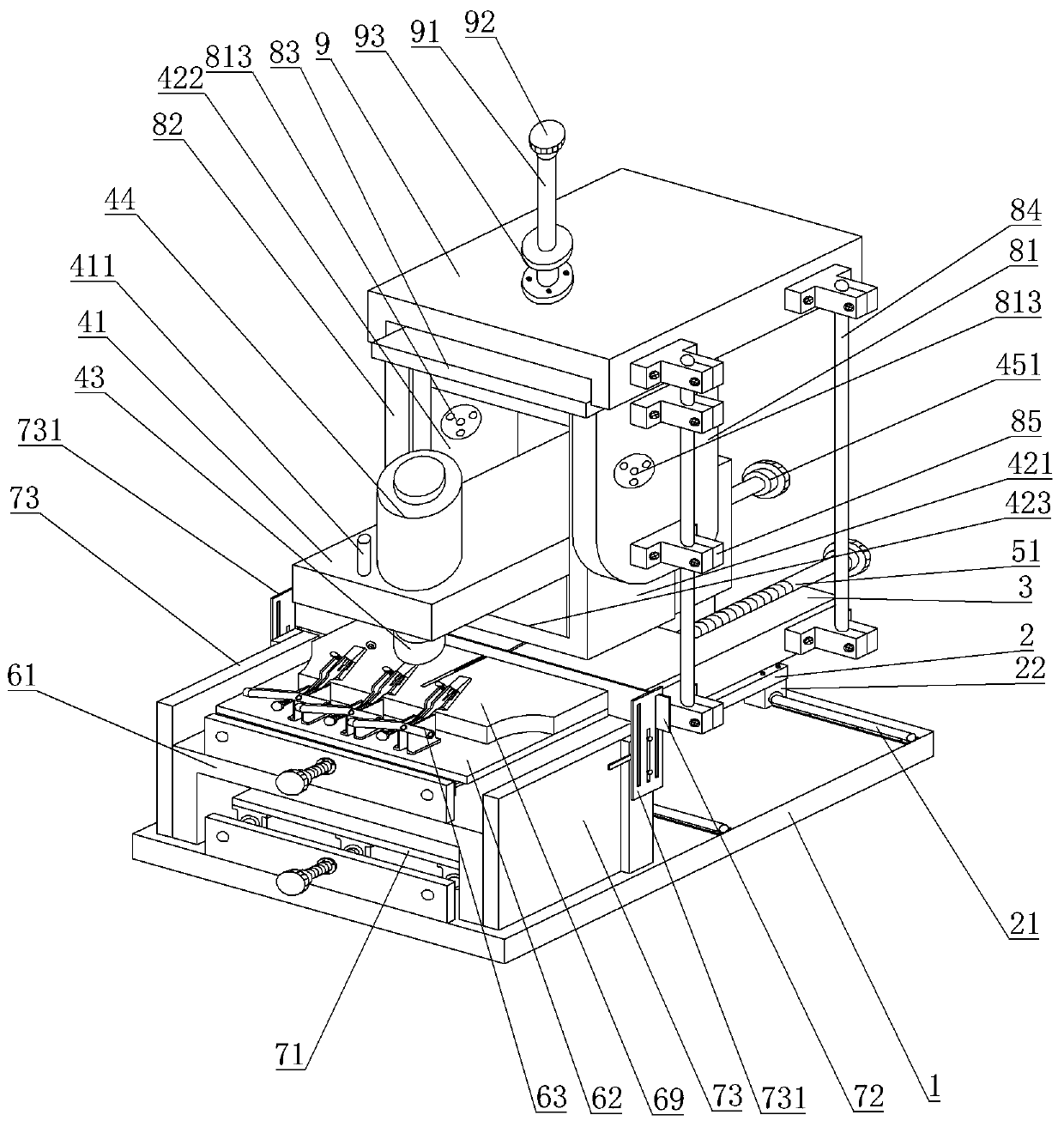

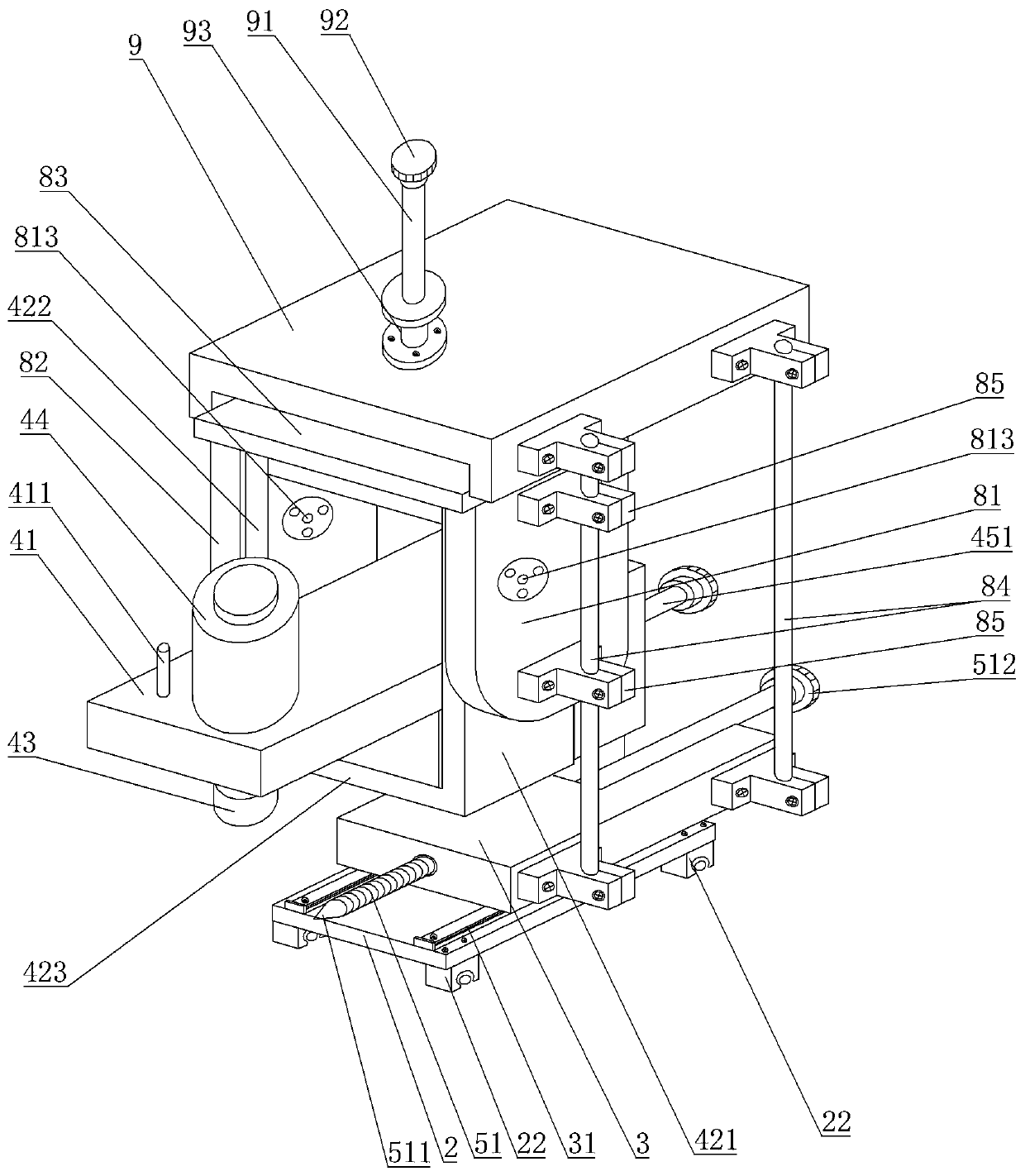

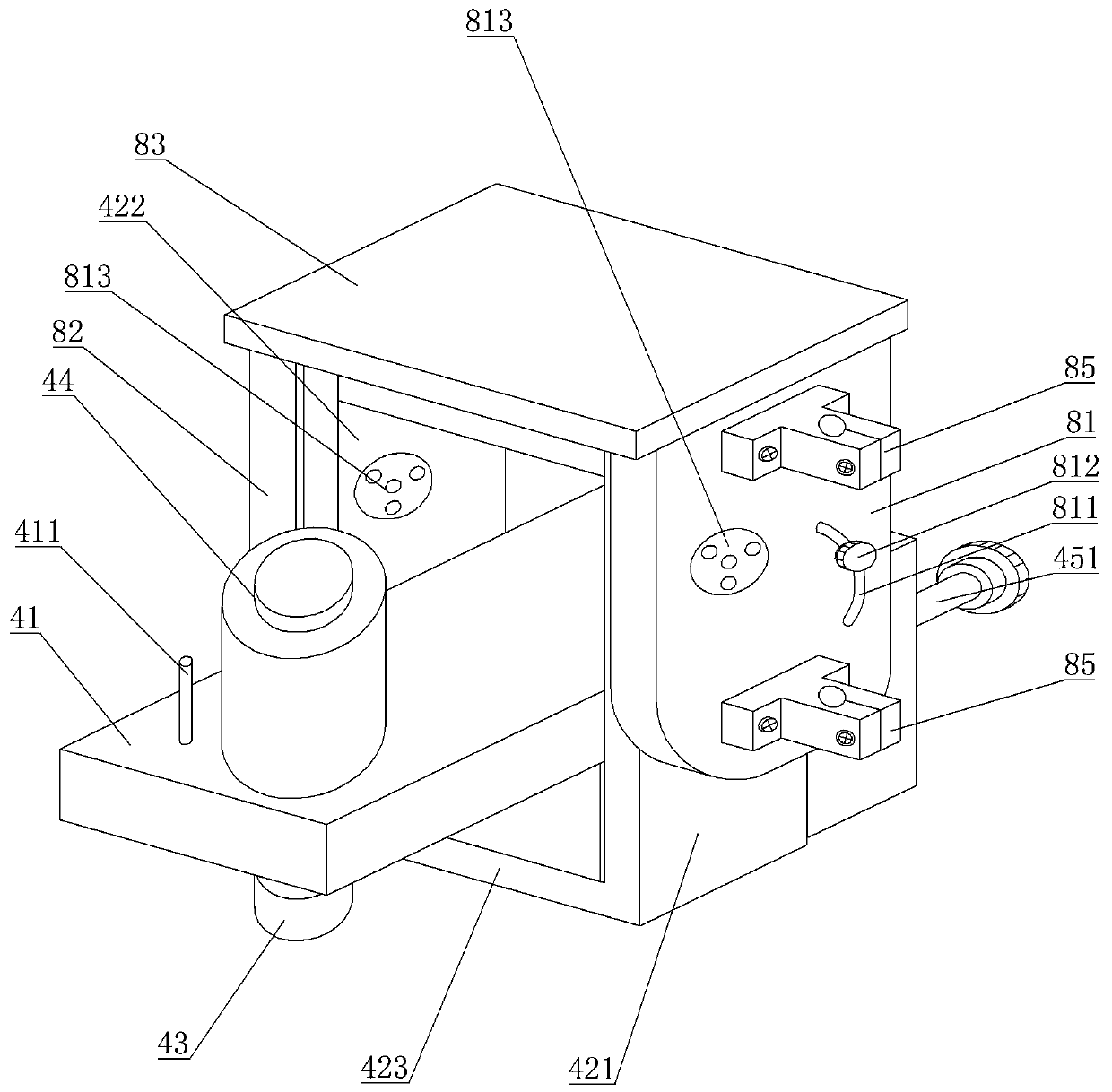

[0028] Embodiment 1: as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 5 , attached Image 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 and Figure 10 As shown, the variable profile sharpening machine includes a frame 1, one end of the frame 1 is provided with a reciprocating sliding first sliding seat 2, and the first sliding seat 1 is provided with a reciprocating sliding first sliding seat 2. Two sliding seats 3, the second sliding seat 3 is provided with a grinding device and a guiding device, the other end of the frame is provided with a pressing device, and a guiding device is arranged between the pressing device and the guiding device Matching profiling device. The pressing device is used to press the tool to be ground, the grinding device is used to grind the tool, the guide device is used to guide the direction of the grinding device, the first sliding seat and the second sliding seat can slide along the direc...

Embodiment 2

[0042] Embodiment 2: as Figure 4 As shown, the guide device includes a master guide pin 51, and the two ends of the second sliding seat 3 are respectively provided with a first through groove 52 and a second through groove 53, and the first through groove 52 is provided with a second through groove. Three chute 54, the third chute 54 is matched with a first slide 55, one end of the master guide pin 51 passes through the first slide 55 and is threadedly connected with the first slide 55, so The other end of the master guide pin 51 passes through the second through slot 53 . The length of the cam guide pin 51 can be adjusted by rotating itself, and the horizontal position of the first sliding plate 55 can be adjusted by fluctuating the position of the third chute 54, so that the horizontal position of the cam guide pin can be adjusted. In this embodiment, other parts are the same as those in Embodiment 1 and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com