Bearing ring shaping device and method

A bearing ring and shaping device technology, which is applied in the field of bearing manufacturing, can solve the problems of large wall thickness changes, difficulty in molding or mold deformation, complex structure, etc., and achieve high shaping efficiency, meet the needs of shaping, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

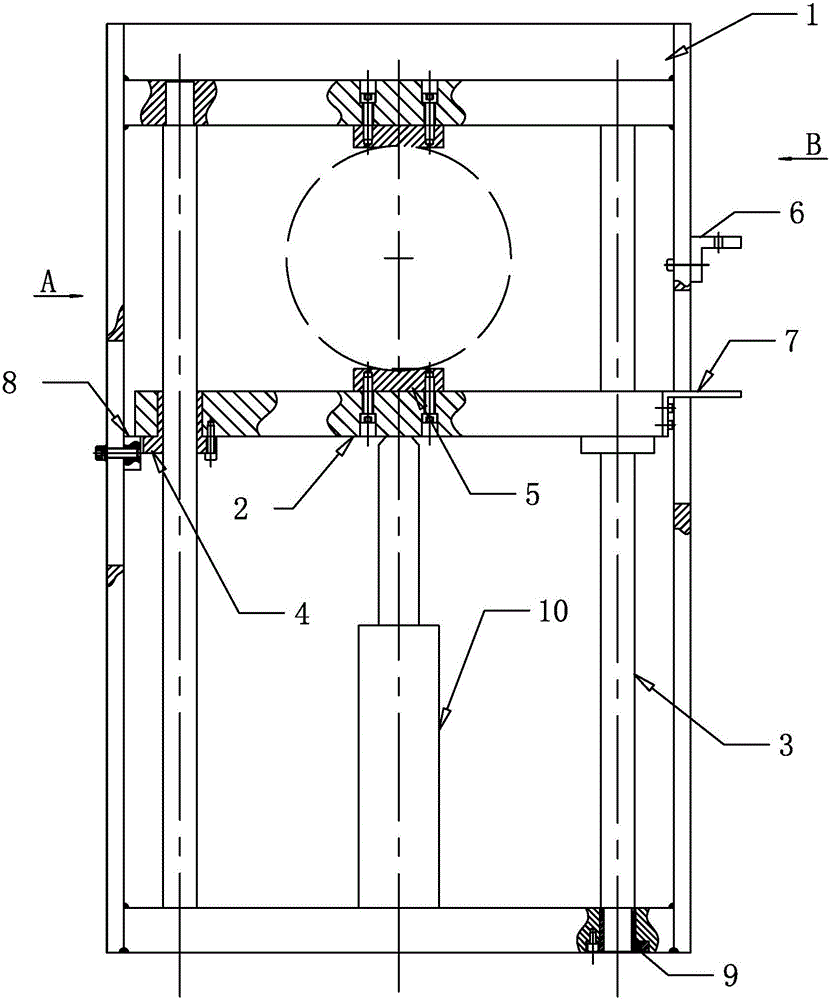

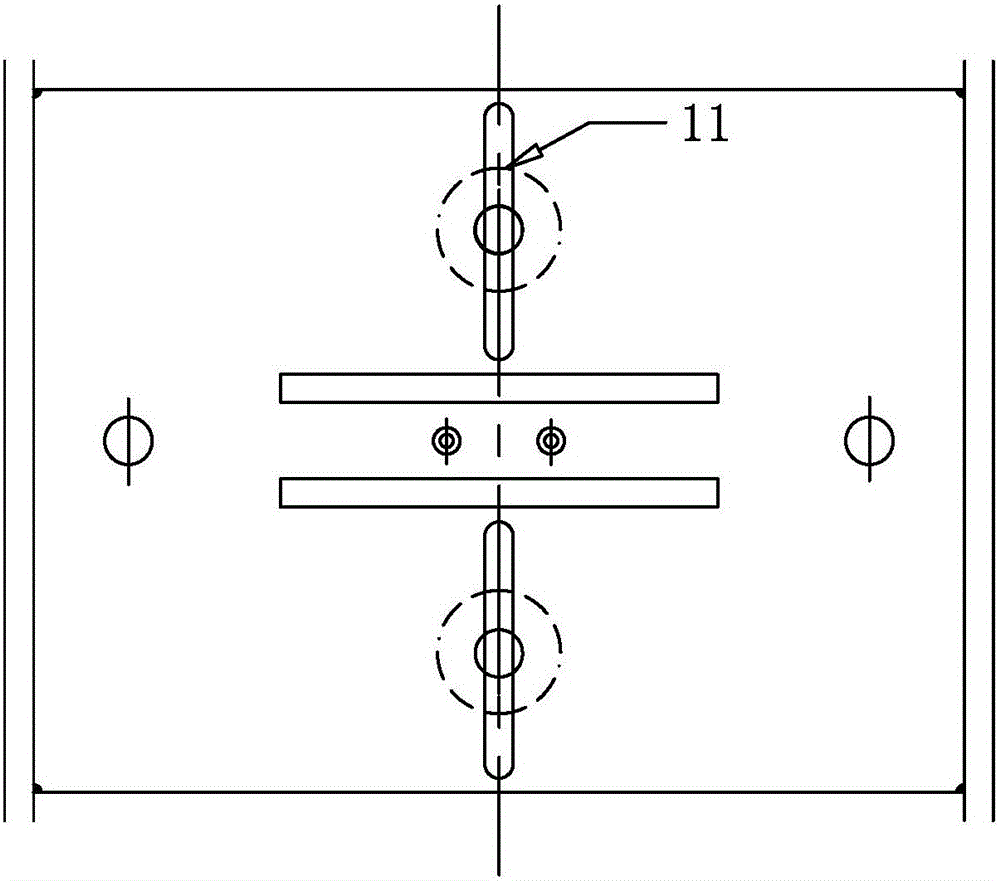

[0018] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a bearing ring shaping device described in this embodiment includes a main body frame 1, a lifting beam 2, two guide columns 3, two guide sleeves 4, two fixed pads 5, an instrument seat 6, a positioning Platform 7, limit block 8, jack 10 and two adjustable columns 11, two guide columns 3 are installed vertically side by side in the main frame 1, and the upper ends of the two guide columns 3 are fixedly connected with the main frame 1, and the lifting The beam 2 is horizontally arranged in the main frame 1, and one end of the lifting beam 2 is slidably connected to a guide column 3 through a guide sleeve 4, and the other end of the lifting beam 2 is slidably connected to another guide column 3 through another guide sleeve 4, The jack 10 is arranged at the bottom in the main body frame 1, and the piston rod of the jack 10 is connected with the middle part of the lower surface of the ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, a bearing ring shaping device described in this embodiment also includes a positioning bolt 9 and a limit block 8, the limit block 8 is installed on the inner side wall of the main body frame 1 through the positioning bolt 9, and the limit block 8 is located below the lifting beam 2. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the specific steps of a bearing ring shaping method described in this embodiment are as follows:

[0021] Step 1: Measure the ellipticity of the bearing ring 12 after quenching with an instrument, and mark the two points where the ellipse deformation of the bearing ring 12 is maximum;

[0022] Step 2, placing the marked bearing ring 12 between the two fixed blocks 5, and making the two points with the largest elliptical deformation of the bearing ring 12 contact with the surfaces of the two fixed blocks 5 respectively;

[0023] Step 3, drive the jack 10 to exert pressure on the maximum elliptical deformation of the bearing ring 12, and read out the size of the plastic size through the measuring instrument arranged on the instrument base 6 during the force application process;

[0024] Step 4: After the shaping is completed, the bearing ring 12 is removed from between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com