Motor stator coil reshaping method and device

A technology of motor stator and coil, applied in the field of motor stator coil shaping and equipment, can solve the problems of affecting the qualified rate of stator installation and use, easily damaged wire insulation layer, and large roundness of the outer diameter of the coil, etc., achieving small roundness and improving shaping Qualified rate, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

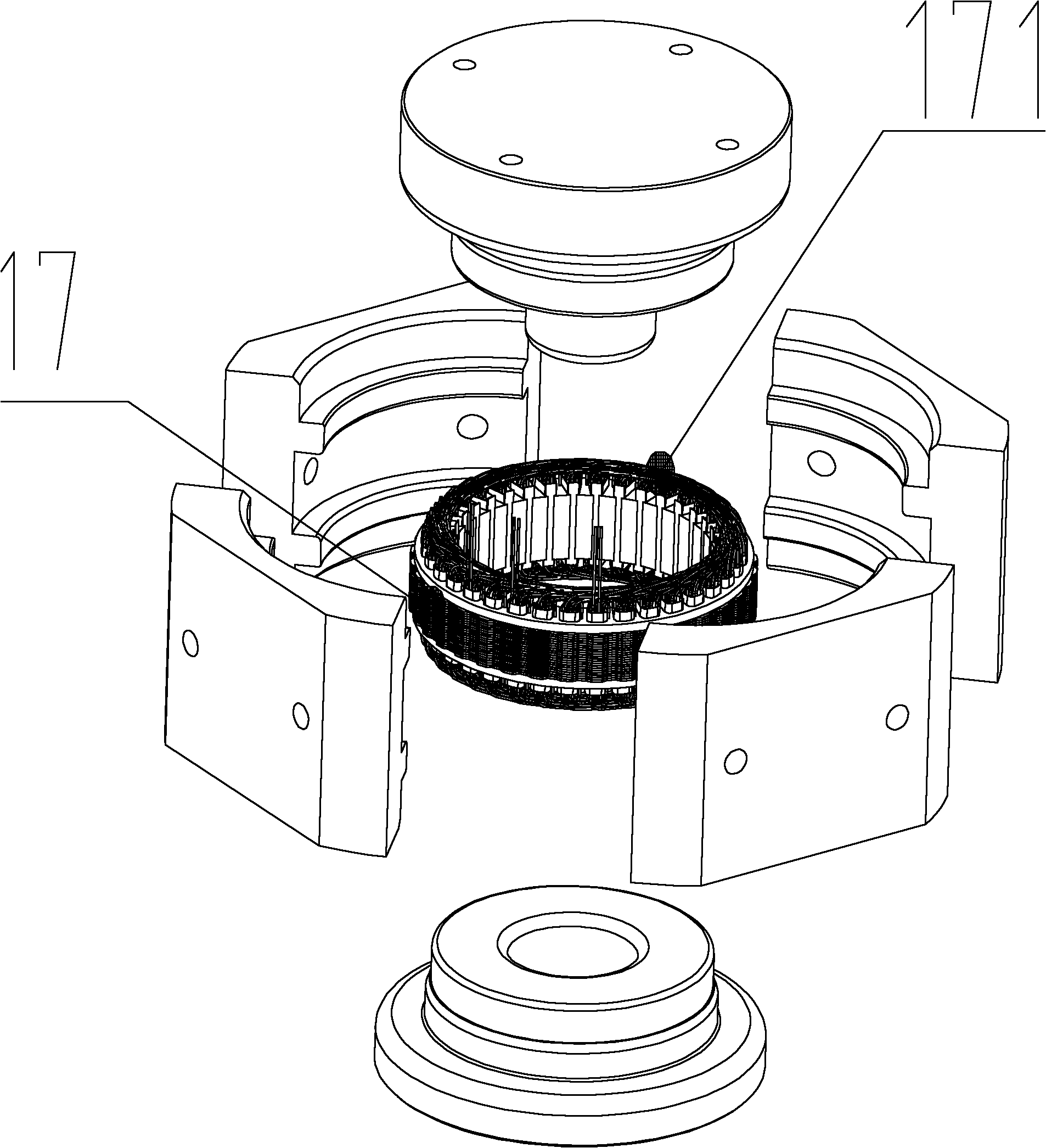

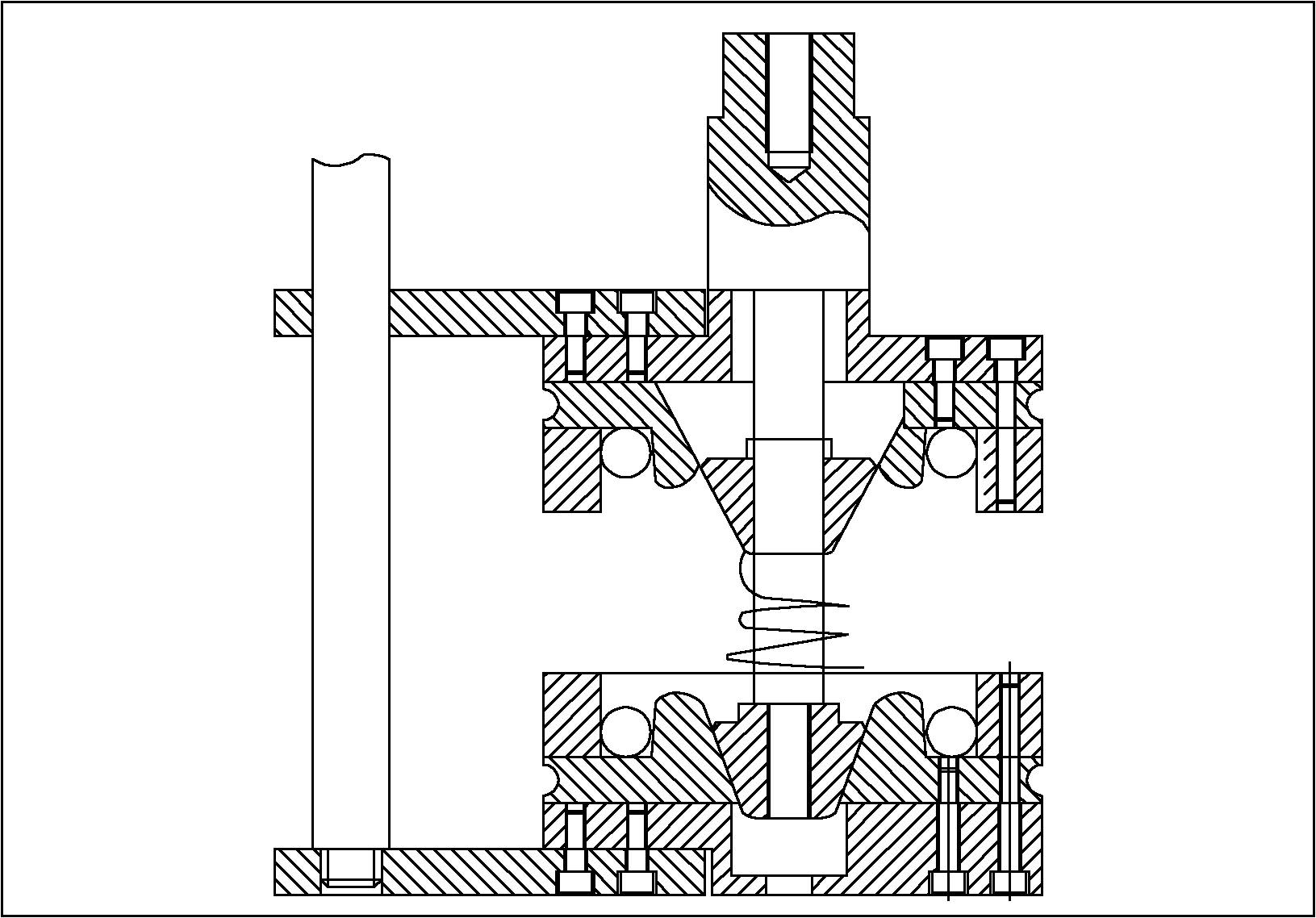

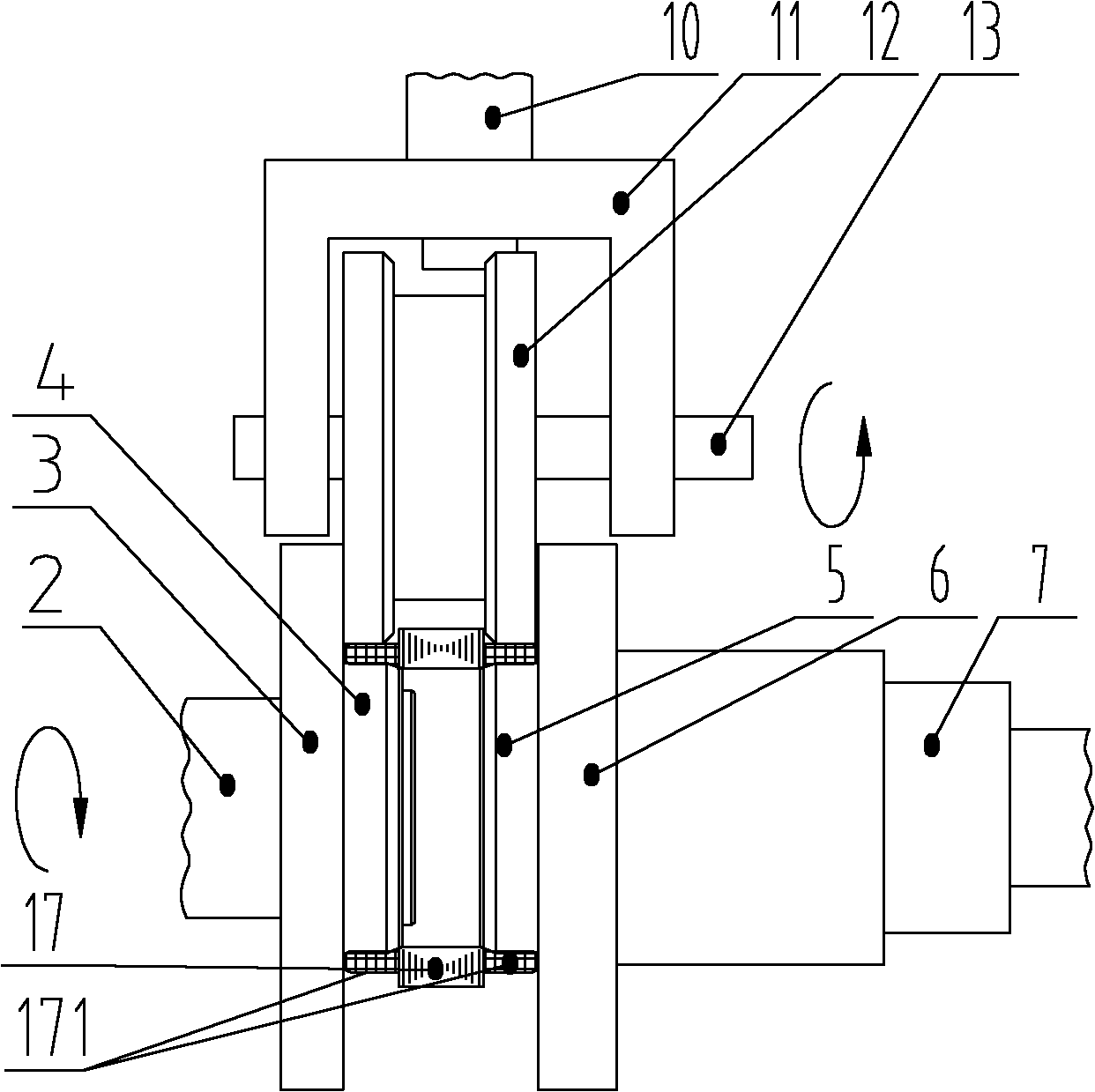

[0035] Such as image 3 , 4 As shown, the motor stator coil shaping device includes a driving motor 16 with a reducer 1, a cylinder 8 of a lateral movement mechanism, a cylinder 9 of a longitudinal movement mechanism, a control switch 14 and a shaping fixture.

[0036] The above-mentioned shaping jig includes a left flange 3, a squeeze wheel 4, a positioning mandrel 5, a right flange 6, a roller 12, a roller shaft 13 and a roller bracket 11. The extrusion wheel 4 is bolted to the left flange 3, the left flange 3 is rigidly connected to the reducer shaft 2, the fixed mandrel 5 is bolted to the right flange 6, the right flange 6 is set on the cylinder shaft 7, and the roller 12 passes through the roller Axle 13 is contained on the roller support 11, and roller support 11 is contained on the cylinder axle 10 of cylinder 9, and roller axle 13 is vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com