A light beam shaping apparatus

A beam shaping and beam technology, applied in optics, optical components, instruments, etc., can solve the problems of short working distance, large divergence angle, and insufficient utilization of beam, and achieve the effect of reducing loss and improving shaping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. However, the present invention can be implemented in many different forms, and the present invention should not be construed as being limited to the specific embodiments set forth herein. On the contrary, these embodiments are provided to explain the principle of the present invention and its practical application, so that other skilled in the art can understand various embodiments of the present invention and various modifications suitable for specific anticipated applications.

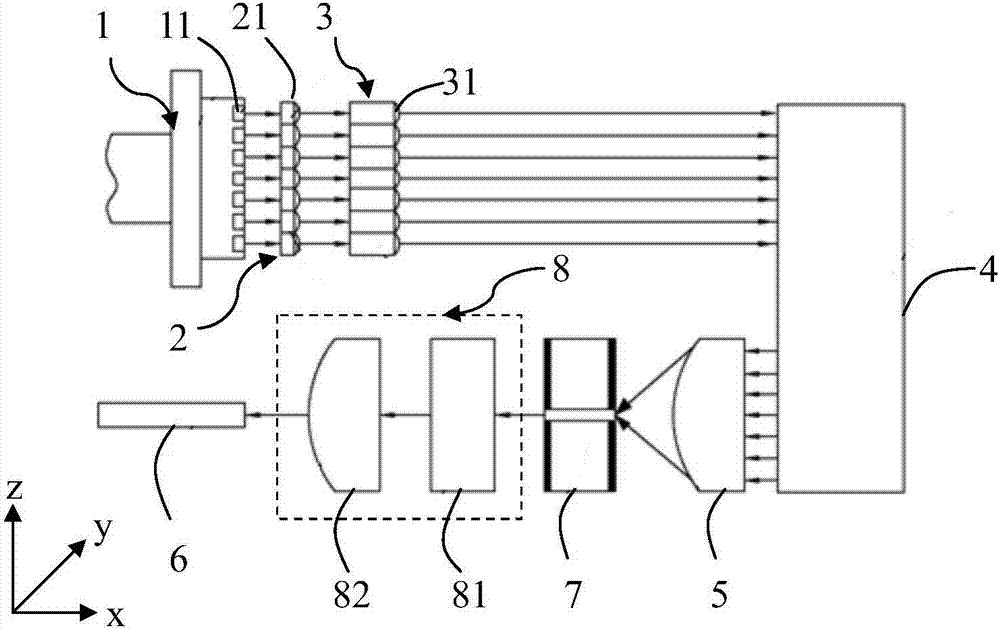

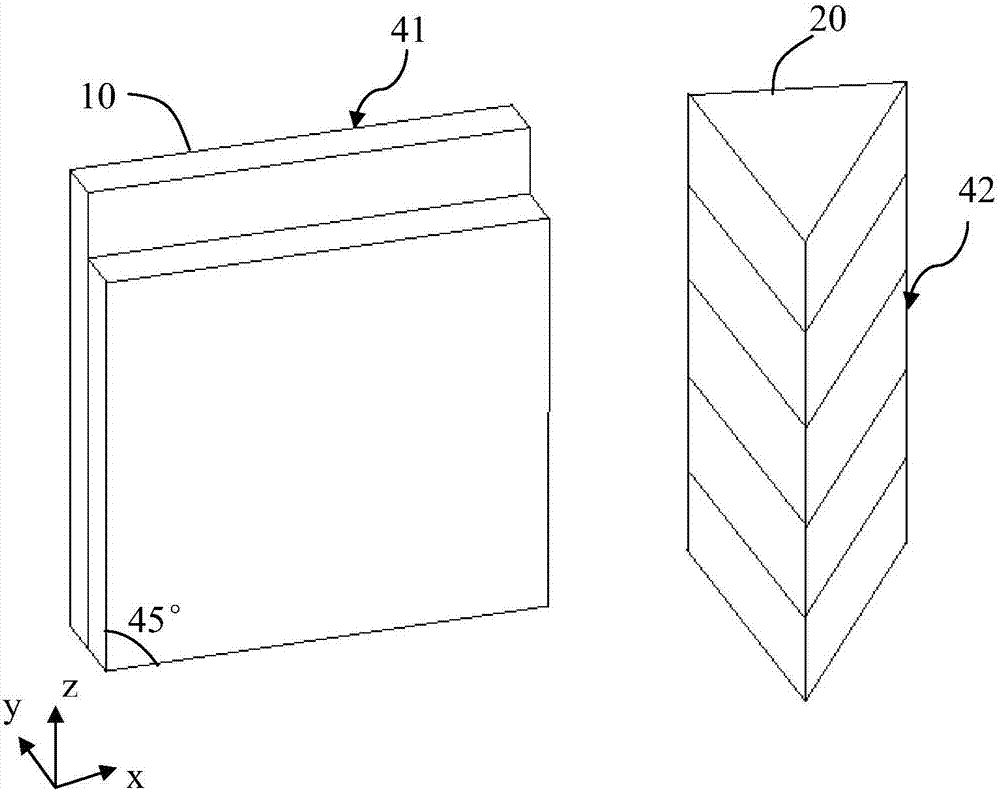

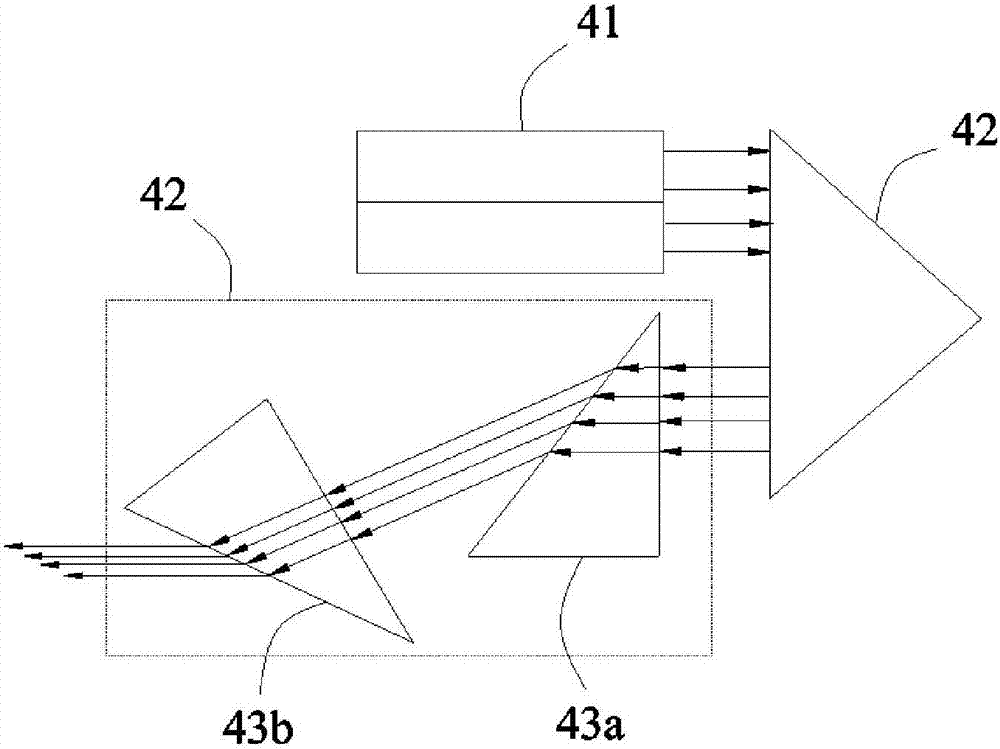

[0023] Reference figure 1 , The beam shaping device provided in this embodiment includes a light source 1, an exit light path (e.g., figure 1 In the x direction), the first lens array 2, the second lens array 3, the beam shaper 4, the beam concentrator 5, and the first optical fiber 6. The light source 1 includes a plurality of semiconductor lasers 11 arranged in an array, and the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com