Shaping mechanism and shaping method

A connecting rod mechanism and frame technology, which is applied in the field of automation equipment and lithium battery manufacturing equipment, can solve the problems of complex structure, high equipment cost, and low efficiency, and achieve the effect of good shaping quality, high shaping efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

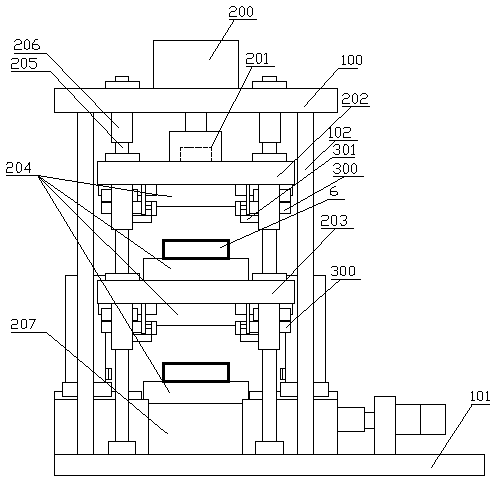

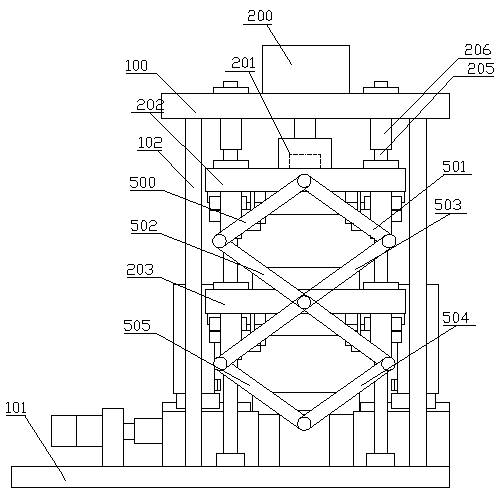

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0024] Coordinates are used in the following descriptions: figure 1 Middle, left, and right are left and right, the direction vertical to the inside of the paper is the back, and vice versa is the front.

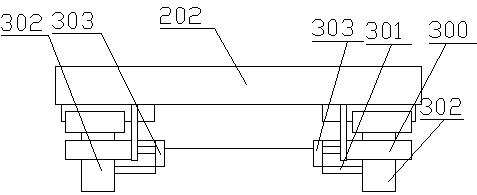

[0025] The main mechanisms included: frame, main pressure mechanism, connecting rod mechanism, side pressure mechanism, and discharge auxiliary mechanism.

[0026] The frame mainly includes a top plate 100, a bottom plate 101 and a support column 102 connecting the top plate 100 and the bottom plate 101. In the embodiment, there are four support columns 102, the lower end of which is fixed on the bottom plate 101, and the upper end is fixedly connected with the top plate 100.

[0027] The main pressure mechanism mainly includes: main pressure driving device 200 (electric cylinder or booster cylinder is used in the embodiment), main pressure sensor 201, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com