Semiconductor laser array fast and slow axis beam rearrangement device and manufacturing method

A laser array and laser beam technology, applied in the application field of laser technology, can solve the problems of difficult assembly, difficult adjustment, and poor shaping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

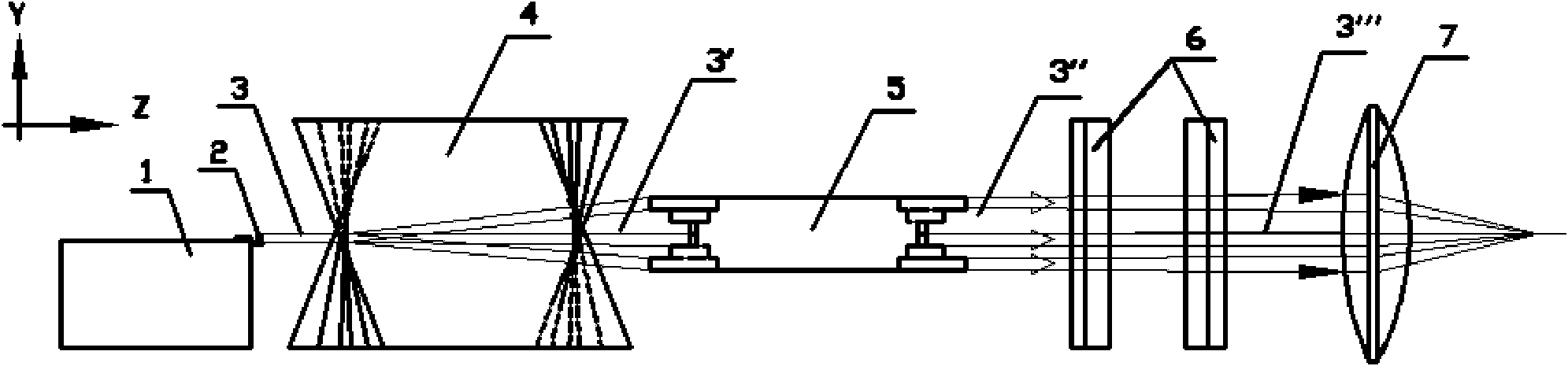

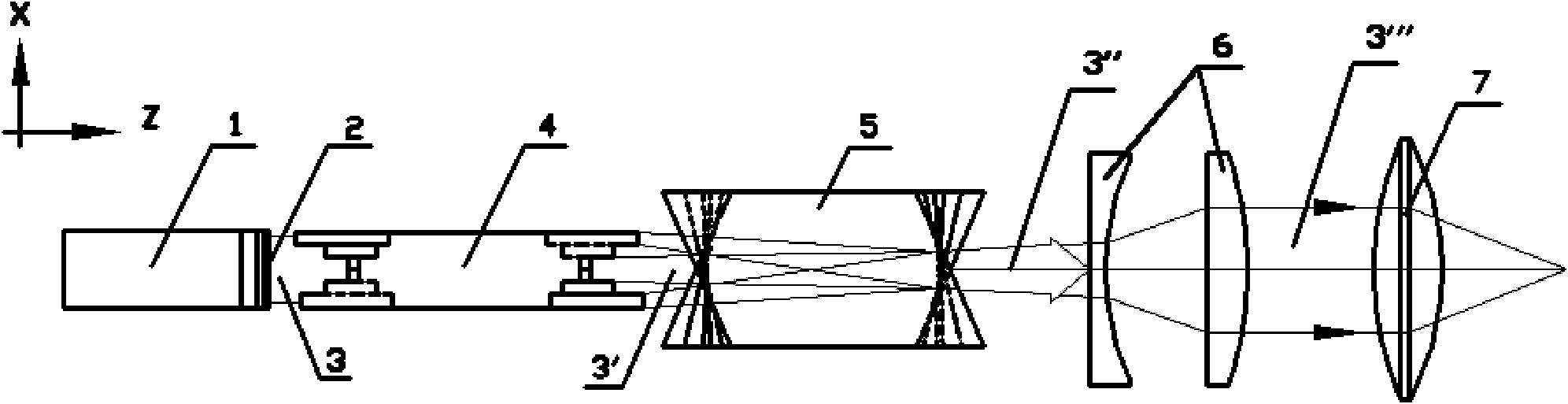

[0048] For one-dimensional semiconductor laser array, the device includes one-dimensional semiconductor laser array 1, fast and slow axis collimating microlens array 2, shaping optical element, 4, shaping optical element 5, slow axis beam expanding collimating cylindrical lens group 6 and spherical surface Focus lens 7, such as figure 1 , figure 2 Shown. In the figure, the x direction is the slow axis direction of the one-dimensional semiconductor laser array, the y direction is the fast axis direction of the one-dimensional semiconductor laser array, and the z direction is the beam transmission direction of the one-dimensional semiconductor laser array.

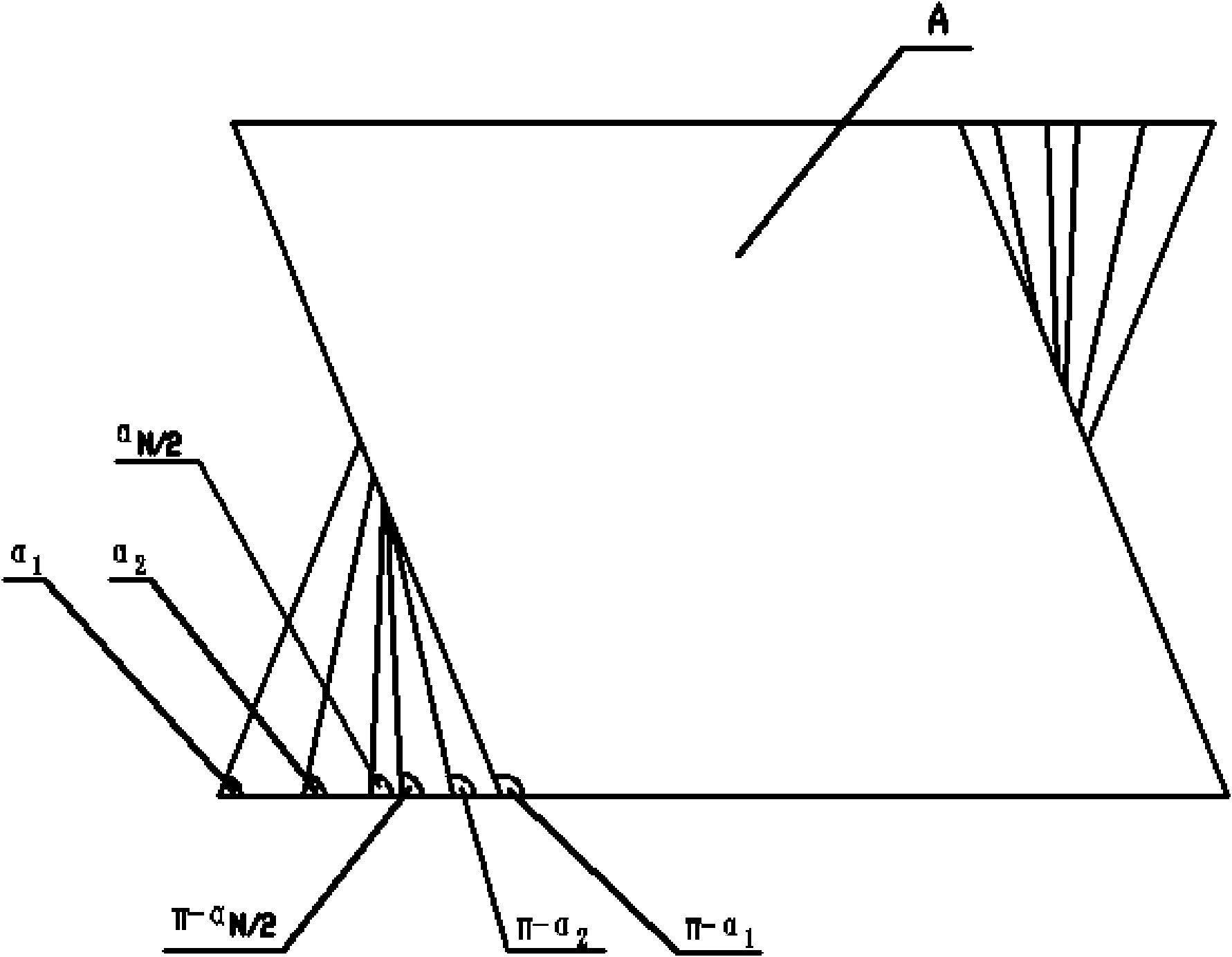

[0049] The light emitted by the one-dimensional array of semiconductor lasers is a stripe spot 3, such as Figure 7 Shown in. Through the divergence angle and spot size of the fast and slow axis of the semiconductor laser one-dimensional array, the fast axis beam quality BPP can be calculated according to the calculation form...

Embodiment 2

[0052] For the semiconductor laser two-dimensional close-packed array, the device includes a semiconductor laser two-dimensional close-packed array 8, a fast and slow axis collimating microlens array 2, a cylindrical lens group for compressing the size of the fast axis 9, a shaping optical element 4, Shaping optical element 5, slow axis beam expanding collimating cylindrical lens group 6 and spherical focusing lens 7, such as Picture 9 , Picture 10 Shown. In the figure, the x direction is the slow axis direction of the semiconductor laser two-dimensional close-packed array, the y direction is the fast axis direction of the semiconductor laser two-dimensional close-packed array, and the z direction is the beam transmission direction of the semiconductor laser two-dimensional close-packed array.

[0053] The light emitted by the two-dimensional close-packed array of semiconductor lasers is a strip-shaped spot 10, such as Picture 11 Shown in. Through the divergence angle and spot...

Embodiment 3

[0056] For the semiconductor laser two-dimensional non-close-packed array, the device includes a semiconductor laser two-dimensional non-close-packed array 11, a fast and slow axis collimating microlens array 2, a shaping optical element 4, and k shaping optical elements 5 closely arranged vertically ( k is the number of bars in the two-dimensional non-close-packed semiconductor laser array), the slow axis beam expanding collimating cylindrical lens group 6 and the spherical focusing lens 7, such as Picture 12 , Figure 13 Shown. In the figure, the x direction is the slow axis direction of the two-dimensional non-closed array of semiconductor lasers, the y direction is the fast axis direction of the two-dimensional non-closed array of semiconductor lasers, and the z direction is the beam transmission of the two-dimensional non-closed array of semiconductor lasers. direction.

[0057] The light emitted by the two-dimensional non-close-packed array of semiconductor lasers is k str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com